Фітынгі для гідраўлічных шлангаў выкарыстоўваюцца для злучэння гідраўлічныя шлангі, трубы і шлангі да помпаў, клапанаў, цыліндраў і іншых кампанентаў гідраўлічнай сістэмы. Існуе мноства тыпаў, формаў, матэрыялаў, разьб і варыянтаў ушчыльнення для гідраўлічных шлангавых муфт. Выбар няправільнай муфты можа знізіць эфектыўнасць усёй гідраўлічнай сістэмы і нават стварыць праблемы бяспекі. Калі вы не ўпэўненыя ў тыпах гідраўлічных шлангавых фітынгаў, вы можаце звярнуцца да нашага кіраўніцтва, каб даведацца, як выбраць найбольш прыдатныя фітынгі для вашых гідраўлічных работ.

Што такое гідраўлічныя фітынгі?

Гідраўлічная арматура — гэта механічныя дэталі, якія выкарыстоўваюцца для злучэння розных частак гідраўлічнай сістэмы (напрыклад, труб, шлангаў і шлангаў). Яны дазваляюць вадкасці бесперашкодна цячы па ўсёй сістэме, тым самым дасягаючы аптымальнай функцыянальнасці.

Фітынгі выпускаюцца ў розных формах і памерах, каб вытрымліваць высокі ціск і ваганні тэмпературы. Да розных тыпаў гідраўлічных шлангавых фітынгаў адносяцца каленныя, прамыя, трайнікавыя і крыжападобныя фітынгі, і кожны тып фітынга мае сваё спецыфічнае прымяненне ў сістэме.

Гідраўлічны шланг у зборы — выберыце гідраўлічныя фітынгі для абціскання

Падчас працэсу зборкі шланга неабходна вырашыць, які тып гідраўлічных фітынгаў выкарыстоўваць. Абціскныя фітынгі - гэта найбольш распаўсюджаны метад зборкі гідраўлічных шлангаў. Як выбраць адпаведныя фітынгі для зборкі шланга? Перад пачаткам зборкі любога шланга неабходна пацвердзіць пяць асноўных праблем, звязаных са штампам раздыма шланга (памер, тэмпература, прымяненне, матэрыял/асяроддзе і ціск)Пасля таго, як гэта будзе вызначана, тэхнікі па зборцы шлангаў могуць пачаць працэс абціскання гідраўлічнага шланга і фітынгаўДык як жа выканаць абцісканне гідраўлічнага шланга і фітынгаў? Гэты працэс можа адрознівацца ў залежнасці ад мадэль абціскной машыны, але звычайна тэхнікі адзначаюць глыбіню ўстаўкі на шлангу, наносяць змазку на фітынгавы стрыжань, уціскаюць яго ў канец шланга, а затым устаўляе яго ў абціскальную форму. Нарэшце, тэхнікі прыкладаюць ціск, запускаючы сілавую прыладу абціскальнай машыны, каб канчаткова зафіксаваць раз'ём на шлангу. Тэхнікі па зборцы шлангаў могуць дапамагчы вам знайсці найлепшыя гідраўлічныя фітынгі і адказаць на любыя вашы пытанні.

Тып матэрыялу фітынгаў шланга

Матэрыял, які выкарыстоўваецца для фітынгаў гідраўлічных шлангаў, вызначае іх характарыстыкі. Найбольш распаўсюджаныя фітынгі вырабляюцца са сталі, нержавеючай сталі, латуні або пластыка.

Сталёвыя фітынгі і фітынгі з нержавеючай сталі вырабляюцца з жалеза і іншых металаў, што робіць іх больш трывалымі і паляпшае іх цеплаўстойлівасць.

напрыклад, фітынгі з вугляродзістай сталі выраблены з сумесі жалеза і вугляроду, можа вытрымліваць тэмпературы ад -65°F да 500°F.

Фітынгі з нержавеючай сталі можа выкарыстоўвацца ў дыяпазоне рабочых тэмператур ад -425°F да 1200°F.

Яны ідэальна падыходзяць для асяроддзяў з высокай рызыкай карозіі. Як правіла, іх намінальны ціск можа дасягаць 10 000 фунтаў на квадратны дюймНекаторыя спецыяльна распрацаваныя Фітынгі з нержавеючай сталі маюць намінальны ціск да 20 000 фунтаў на квадратны дюйм.

Латуневыя фітынгі маюць меншую трываласць і даўгавечнасць у параўнанні з нержавеючай сталі. Але яны таксама могуць працаваць без уцечак і адпавядаць стандартам SAE, ISO, DIN, DOT і JIS. Тэмпературны дыяпазон латуневых фітынгаў складае ад -65°F да 400°F. Яны могуць вытрымліваць ціск да 3000 psi, але звычайна рэкамендуецца выкарыстоўваць больш нізкі дыяпазон ціску.

Пластыкавыя фітынгі менш папулярныя ў гідраўлічных прыладах. Звычайна яны лічацца больш устойлівымі да карозіі, але маюць меншую трываласць і даўгавечнасць. Таму, нягледзячы на іх нядорагасць, з-за больш высокага намінальнага ціску металічных фітынгаў яны больш папулярныя ў гідраўлічнай прамысловасці.

Алюмініевыя фітынгі значна лягчэйшыя за сталёвыя і больш устойлівыя да карозіі. Дзякуючы сваёй невялікай вазе яны шырока выкарыстоўваюцца ў аўтамабільнай прамысловасці.

Тыпы фітынгаў для гідраўлічных шлангаў

Два асноўныя тыпы:

Пастаянныя абціскныя фітынгі (абціскныя фітынгі) - найбольш распаўсюджаны тып фітынгаў. Для гэтых фітынгаў патрабуецца абціскны станок для мацавання шланга да фітынга.

Прымацоўваецца ў палявых умовах (фітынгі з націскным замкам) - Калі вы не можаце выкарыстоўваць абціскальныя інструменты, а ваш шланг сумяшчальны з "фітынгамі, якія падключаюцца ў палявых умовах", то яны - выдатны выбар.

Тыпы фітынгаў і раздымаў, як паказана ніжэй:

Гідраўлічныя кампаненты маюць розныя тыпы канцоў і раздымаў, такія як фланцавыя канцы, разьбовыя злучэнні для труб і канічныя разьбовыя злучэнні. Выбар кожнага тыпу залежыць ад канкрэтных патрабаванняў гідраўлічнай сістэмы.

Разуменне гэтых тыпаў раздымаў мае вырашальнае значэнне для падтрымання бяспечных і эфектыўных гідраўлічных аперацый.

Фітынгі ORFS маюць канструкцыю з ушчыльняльным кольцам высокага ціску, што забяспечвае высокую бяспеку працы.

Паколькі яны могуць вытрымліваць высокі ціск і моцныя ўмовы вібрацыі, яны шырока выкарыстоўваюцца ў гідраўлічных прыборах.

Прыклады ORFS ўключаюць:

Прамое разьбовае ўшчыльняльнае кольца (STO): вядомае сваім трывалым і надзейным механізмам ушчыльнення, яно дасягае выдатнай герметычнасці дзякуючы выкарыстанню прамой разьбы і ўшчыльняльных кольцаў. Каленавыя аксэсуары ORFS, трохбаковыя аксэсуары ORFS і крыжаваныя аксэсуары ORFS.

Гэтыя кампаненты адпавядаюць стандарту BSP і часта выкарыстоўваюцца ў гідраўлічных сістэмах высокага ціску дзякуючы сваёй здольнасці забяспечваць герметычнасць у экстрэмальных умовах.

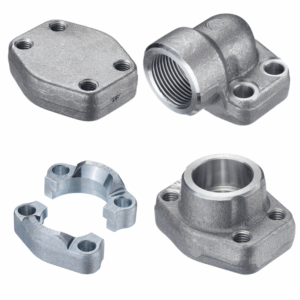

Фланцавыя фітынгі

Гэтыя фітынгі спецыяльна распрацаваны для гідраўлічных прымяненняў высокага ціску і лёгка ўсталёўваюцца і здымаюцца. Яны асабліва падыходзяць для буйных прымяненняў, якія патрабуюць больш высокага ціску. Фланцавыя фітынгі могуць размеркаваць нагрузку на падшыпнік па большай плошчы, тым самым забяспечваючы надзейнае злучэнне і вытрымліваючы высокі ціск і вялікія нагрузкі.

Раз'ёмы для трубнай разьбы

Гэта найбольш распаўсюджаны тып гідраўлічнага кампанента ў сістэмах сярэдняга і нізкага ціску. Раз'ём з трубнай разьбой утварае герметычнае ўшчыльненне за кошт дэфармацыі самой разьбы. Яны бываюць розных тыпаў і памераў, каб задаволіць патрабаванні розных гідраўлічных сістэм.

Канічныя разьбовыя злучальнікі

Гэтыя злучэнні падобныя да раз'ёмаў з трубнай разьбой, але разьба мае канічную форму. Канічная форма дазваляе разьбе ўтвараць герметычнасць пры зацягванні, і яны звычайна выкарыстоўваюцца ў гідраўлічных сістэмах сярэдняга і высокага ціску.

Як выбраць правільныя гідраўлічныя фітынгі

Тып ушчыльнення і тып разьбы

Калі вы карыстаецеся Фітынгі з трубнай разьбой NPT (National Pipe Thread), будзьце вельмі асцярожныя. Нягледзячы на тое, што выкарыстанне такіх фітынгаў для рамонту ўцечак здаецца простым, дастаткова проста зацягнуць фітынгі, але гэта можа павялічыць рызыку паломкі фітынга. Паўторная замена (адкручванне і паўторнае зацягванне фітынга) часцей узнікае. Каб прадухіліць выпадковыя ўцечкі, выкарыстоўвайце эластычныя ўшчыльняльныя кольцы, якія адпавядаюць такім стандартам, як DIN 2353, SAE J1453 і г.д., і пераходзьце на неканічныя фітынгі JIC. Калі вы выкарыстоўваеце эластычныя ўшчыльняльныя кольцы, падтрымлівайце тэмпературны рэжым у рэкамендаваным дыяпазоне. На жаль, нават адзін перагрэў можа пашкодзіць усе ўшчыльняльныя кольцы і выклікаць множныя ўцечкі.

Узровень ціску

Гідраўлічнае абсталяванне звычайна працуе з больш высокім рабочым ціскам. Каб адаптавацца да высокага працоўнага ціску, усё больш кліентаў аддаюць перавагу выкарыстоўваць ушчыльняльныя кольцы. Яны больш устойлівыя да расколін. Ушчыльняльныя кольцы таксама могуць перацягвацца і ўцякаць. Што тычыцца матэрыялу, то фітынгі для шлангаў з нержавеючай сталі маюць найвышэйшы намінальны ціск.

Вібрацыя

Вібрацыя можа паўплываць на гідраўлічныя шлангі, што можа прывесці да зменаў крутоўнага моманту і стомленасці матэрыялу. Абавязкова праверце на наяўнасць уцечак або пашкоджанняў у месцах са значнай вібрацыяй.

Температура

Тэмпературны дыяпазон фітынга шланга вызначаецца трыма фактарамі: матэрыялам, пакрыццём і ўшчыльненнем (калі выкарыстоўваецца). Каб дасягнуць безуцечнай працы, калі дазваляе рабочая тэмпература, выкарыстоўвайце ўшчыльняльнае кольца. Калі ласка, звярніцеся да табліцы ніжэй, каб зразумець тэмпературныя дыяпазоны найбольш распаўсюджаных фітынгаў і ўшчыльняльных матэрыялаў. Калі вам патрэбныя гідраўлічныя шлангі і фітынгі для працы пры экстрэмальных тэмпературах, мы прапануем спецыяльныя варыянты. Звяжыцеся з намі для атрымання дадатковай інфармацыі.

Хімічная сумяшчальнасць і рабочая вадкасць

Зыходзячы з вопыту, унутраная трубка, вонкавая абалонка, фітынгі і ўшчыльняльныя кольцы шланга павінны быць хімічна сумяшчальныя адзін з адным. Пры выбары шлангаў для газавых прымяненняў варта быць асабліва асцярожнымі, асабліва ў выпадках, калі ёсць верагоднасць уцечкі, каб пазбегнуць выбухаў, пажараў і ўздзеяння таксічных газаў. Абавязкова пракансультуйцеся з вытворцам, каб пацвердзіць хімічную сумяшчальнасць гідраўлічнага шланга і фітынгаў гідраўлічнай сістэмы. Акрамя таго, звярніце ўвагу на сумяшчальнасць ушчыльненняў з тыпам гідраўлічнага алею, які выкарыстоўваецца ў сістэме.

Зручнасць выкарыстання

Усё ішло гладка, пакуль вам не спатрэбілася замяніць дэталі. Цыкл пастаўкі складае ўсяго некалькі тыдняў, і яны патрэбныя вам зараз. Звычайна большасць дэталяў NPT і JIC ёсць у наяўнасці ў дастатковым аб'ёме, і ёсць розныя канфігурацыі на выбар. Таму, калі вы выкарыстоўваеце якія-небудзь канкрэтныя дэталі з доўгім цыклам пастаўкі, калі ласка, выбірайце тыя, якія лягчэй знайсці або маюць большы запас.

Калі вы шукаеце надзейныя гідраўлічныя фітынгі — Синопульс тут, каб дапамагчы. І калі вы хочаце атрымаць бясплатныя ўзоры або даведацца больш пра тыпы гідраўлічных фітынгаў, калі ласка звяжыцеся з намі.