Фитинги за маркучи are key components in hydraulic systems, used to connect hoses to equipment and ensure the efficient and safe flow of fluids. The hose fittings type is important to system performance, reliability, and maintenance requirements. Two main types of hose fittings are used in hydraulic systems: two-piece and one-piece hose fittings.

Each type has its unique advantages and potential drawbacks, depending on the application.

One-piece vs. two-piece hydraulic fittings: What's the difference? This blog post explores the key distinctions between these fitting types, helping you choose the right one for your hydraulic system. Learn about assembly, reliability, cost, and applications, helping you make an informed decision for your specific application.

Two-piece and one-piece hose fittings: How to choose?

The choice between two-piece and one-piece hose fittings depends on the specific requirements of the hydraulic system, including working pressure, environmental conditions, as well as factors such as flexibility and ease of assembly.

Two-piece hose fittings offer greater adaptability and easier assembly in complex or customized systems, making them suitable for scenarios that require frequent adjustments or customization.

On the other hand, one-piece couplings provide a sturdy and leak-proof solution and are ideal for high-pressure applications or environments that require a safe and reliable connection.

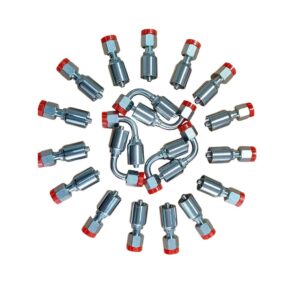

Two-Piece Hose Fittings

The Two-piece fittings is a type of гідраўлічная арматура, consisting of two separate components: the fittings body and the ferrule. Unlike the one-piece fittings, in which the ferrule is permanently connected, in the two-piece hose fittings, the ferrule is an independent component that needs to be installed on the hose first and then connected to the fitting body.

This design provides flexibility in choosing the hose, as the same fitting body can be paired with different ferrules to adapt to various types of hoses and sizes.

The Two-piece hose fittings consists of a stem and a ferrule. It is a widely used and highly adaptable solution in hydraulic systems. The stem part is designed to be inserted into the hose, while complemented by the ferrule, which is crimped around the hose to secure the stem firmly in place.

This assembly method guarantees a robust connection, can be tailored to accommodate a wide variety of hose types and sizes, making two-piece fittings a universal choice for diverse hydraulic applications.

The construction of two-piece hose fittings is such that it allows for a significant degree of flexibility in terms of hose compatibility. Whether dealing with high-pressure scenarios or systems requiring specific hose materials, the two-piece design facilitates a secure and reliable connection.

Moreover, the design of two-piece fittings lends itself well to field assembly and disassembly. This is particularly advantageous in situations where hydraulic systems need to be modified or repaired on-site, offering a practical solution that minimizes downtime and enhances operational efficiency.

While two-piece fittings require a more involved assembly process compared to one-piece fittings, they provide versatility and can be a cost-effective solution for many hydraulic applications.

They are commonly used in situations where a variety of hose types and sizes are needed or where frequent changes to the hydraulic system are required. However, proper assembly is crucial with two-piece fittings to ensure a reliable and leak-free connection.

Перавагі

The main advantage of the two-piece hose fittings lies in its unique design flexibility. The separate piston and ferrule ring components enable various combinations to be achieved, ensuring compatibility with various types of hoses and different sizes of hoses.

This flexibility is particularly important in custom or highly specialized hydraulic systems, as standard connectors may not meet the requirements in such systems.

Another significant advantage is that the assembly process of these accessories is very simple, even in the most complex or space-constrained system configurations. Its two-piece structure allows for adjustments and installations in confined spaces, thus demonstrating unparalleled flexibility in system design.

Недахопы

Potential for Leaks

However, the two-piece design is not without its drawbacks. The presence of multiple components in a single fitting can increase the risk of leaks, especially if not assembled with precision. Ensuring a leak-proof connection requires meticulous attention to detail and proper crimping techniques, which may not always be feasible in fast-paced or field conditions.

Longer Assembly Time

Additionally, the assembly process for two-piece fittings, while flexible, can be more time-consuming compared to one-piece alternatives. This increased assembly time can impact project timelines, especially in large-scale installations or when time is of the essence.

Balancing the benefits of customization and flexibility against the potential for increased labor time is a critical consideration in the selection of hose fittings.

One-Piece Hose Fittings

The One-piece fittings, таксама вядомы як а permanently attached or crimped fittings, is a type of гідраўлічная арматура. Its sealing sleeve is part of the fitting body. This means that the ferrule responsible for gripping the hose is not an independent component but is permanently connected to the main body during the manufacturing process.

This integrated design simplifies the assembly process because there are fewer components to handle, and it reduces the risk of ferrules mismatch, which is more common in two-piece pipe joints.

The One-piece hose fittings is designed as a single, closely connected unit, providing a simple and robust solution for hydraulic connections. Their monolithic structure aims to eliminate potential weak links caused by the assembly of multiple components, which is different from the situation of two-piece pipe fittings.

This design significantly improves the integrity and reliability of the connection, making one-piece fittings a preferred choice for high-pressure applications and environments where durability is paramount.

The construction of one-piece hose fittings is inherently simpler, with no separate ferrules or stems to manage. This simplicity results in a stronger connection between the hose and the fitting, thereby reducing the likelihood of leakage and loosening under pressure. The unified design also helps maintain stable fluid flow and reduces turbulence and resistance that could affect system performance.

The inherent design of the integrated connector makes it particularly suitable for high-pressure applications, as reliable and leak-free connections are crucial in these applications.

Since the sealing ring is already fixed, the assembly process is usually faster and less prone to errors, thereby improving manufacturing and maintenance efficiency. Although they may have less flexibility in hose selection compared to two-piece connectors, their ease of use and reliability make them a popular choice in various hydraulic systems.

Приложения

One-piece hose fittings are particularly suitable for hydraulic systems that require high reliability and ease of maintenance. Their robust design makes them ideal for high-pressure applications, including mobile hydraulic systems, industrial machinery, and heavy equipment.

The inherent strength and leak-proof performance of integral pipe fittings also make them the preferred choice in harsh environments, as these environments often face extreme pressure, high temperatures, and corrosive substances.

These fittings are especially useful in applications where assembly time needs to be minimized and potential leakage situations reduced as much as possible, such as in production lines, aerospace, and the automotive industry.

The simplicity and reliability of integral fittings ensure that hydraulic systems can operate continuously and remain efficient, while minimizing downtime during maintenance or repairs.

Перавагі

The One-piece fittings simplify the installation process, making the installation procedure faster and reducing the possibility of errors. This efficiency can significantly save labor costs and downtime, especially in large-scale operations or when frequent system modifications are not required.

Its simple design means that the required specialized tools or skills are lower, thereby further reducing the time and cost needed for installation.

The single-piece design of these fittings significantly reduces the risk of leaks, which is a common problem in multi-component connection methods.

By eliminating the connection points between individual independent components, one-piece fittings provide a more secure seal, ensuring that hydraulic fluid is contained within the system under all operating conditions.

Недахопы

The rigid nature of one-piece fittings can pose challenges during installation, particularly in tight or complex spaces.

The inability to adjust the components separately means that the hose and fitting must align perfectly, which may not always be feasible in constrained environments. This can lead to difficulties in routing hoses or necessitate changes in system design to accommodate the fittings.

The main drawback of one-piece hose fittings is their limited flexibility when it comes to customization.

The monolithic design, while robust, does not allow for the same level of adaptability as two-piece fittings, making them less suitable for systems requiring specific configurations or frequent modifications.

Key Differences

In the hydraulic fittings world, the choice between one-piece and two-piece hose fittings comes down to a series of trade-offs involving performance, installation convenience, maintenance, and cost. Understanding these differences is crucial for selecting the most appropriate fitting for a given application.

Installation and Maintenance

Maintenance Requirements: The simplicity of one-piece fittings translates into lower maintenance requirements, as fewer components could fail or require adjustments. Two-piece fittings, by nature of their design, might necessitate more frequent checks and adjustments to ensure the integrity of the connection, especially in systems subject to vibration or thermal cycling.

Ease of Installation: One-piece fittings generally offer a quicker and simpler installation process, with fewer steps involved and no need for ferrule management. This can be particularly advantageous in large-scale projects or when time is of the essence. Two-piece fittings require a more complex assembly process, which can be more time-consuming but allows for greater flexibility in fitting and hose combinations.

Long-Term Durability: Both fitting types are designed for durability, but the single-piece construction inherently offers a slight edge in environments where the connection is subjected to continuous stress. Two-piece fittings can be equally durable, provided they are correctly assembled and maintained.

Performance and Reliability

Leak Prevention: One of the most significant advantages of one-piece hose fittings is their superior leak prevention capabilities. The monolithic design minimizes potential failure points, offering a more secure and leak-resistant connection. In contrast, two-piece fittings, while highly versatile, can be more prone to leaks if not assembled correctly due to their multi-component nature.

Cost Implications

Maintenance Costs: Over the life of a hydraulic system, two-piece fittings may incur higher maintenance costs due to the potential need for adjustments or replacements. Conversely, the reduced risk of leaks and lower maintenance requirements of one-piece fittings can result in long-term cost savings.

Initial Costs: The manufacturing process for one-piece fittings is generally more complex, potentially making them more expensive upfront than two-piece fittings. However, the cost must be evaluated in the context of the entire system, considering factors like assembly time and potential for leaks.

Potential Savings: While one-piece fittings might have a higher initial cost, the potential savings in terms of reduced maintenance and downtime can offset this over time. The choice between one-piece and two-piece fittings should, therefore, be made considering both immediate and long-term financial impacts on the system.

Selecting the Right Hose Fitting for Your Application

How to Choose Two Piece Fittings and One Piece

Selecting the right hydraulic fittings is crucial for the performance, reliability, and safety of any hydraulic system. Two primary types of fittings, one-piece and two-piece, offer distinct advantages and disadvantages depending on the specific application.

Understanding these differences, from design and assembly to cost and flexibility, is essential for making informed decisions and ensuring optimal system performance. This guide will delve into the nuances of one-piece and two-piece fittings, helping you choose the best option for your needs.

1. Understand Your Application:

- Патрабаванні да ціску: One-piece fittings are generally preferred for high-pressure applications due to their inherent strength and reduced leak potential. Two-piece fittings can handle high pressures as well, but proper assembly is crucial.

- Hose Type and Size: Two-piece fittings offer greater flexibility in hose selection, accommodating a wider range of types and sizes. One-piece fittings are typically designed for specific hose types.

- Умовы навакольнага асяроддзя: Harsh environments with extreme temperatures, vibrations, or corrosive substances might favor one-piece fittings due to their robustness and fewer potential leak points.

- Сумяшчальнасць з вадкасцю: Ensure the fitting material is compatible with the hydraulic fluid being used to prevent corrosion or degradation.

2. Evaluate Assembly and Maintenance:

- Assembly Complexity: One-piece fittings are simpler and faster to assemble, reducing the risk of errors and saving time. Two-piece fittings require more steps and careful crimping to ensure a reliable connection.

- Maintenance Needs: Consider the ease of replacement and maintenance. One-piece fittings might be easier to replace as a unit, while two-piece fittings allow for individual component replacement.

- Skill Level: If the assembly will be done by less experienced personnel, one-piece fittings might be a safer choice due to their simplicity.

3. Consider Cost and Availability:

- Initial Cost: Two-piece fittings can be more cost-effective upfront. However, the long-term costs of leaks or failures due to improper assembly can outweigh this initial advantage.

- Inventory Management: Two-piece fittings offer greater flexibility in inventory management as you can stock fewer fitting bodies and more ferrules to accommodate different hose types.

- Availability: Consider the availability of both types of fittings in your region and the lead times for ordering.

4. Consult with Experts:

- Hydraulic System Designers: Seek advice from experienced hydraulic system designers or engineers who can help you choose the right fittings for your specific application.

- Fitting Manufacturers: Contact fitting manufacturers for technical support and recommendations on the best fittings for your needs.

5. Consider Future Needs:

- System Expansion: If you anticipate future expansion or modifications to your hydraulic system, consider the flexibility offered by two-piece fittings.

- Technological Advancements: Stay informed about advancements in fitting technology that might offer improved performance or cost-effectiveness.

By carefully considering these factors and consulting with experts, you can make an informed decision about whether one-piece or two-piece fittings are the best choice for your hydraulic system.

Which approach is more preferable for distributors and end-users?

We cannot simply say which one is better. Instead, we can analyze it from the following aspects:

1. The final application;

2. The role as a distributor, repair shop, equipment supplier, etc.;

3. Cost factors.

For instance, as a final user, if you are a mining company, then your requirements for the specifications of the hydraulic hose connector components needed for the relevant machines are relatively limited. Therefore, from this perspective, an integrated connector is more suitable.

If you are a distributor in the local market and your customers come from various industries, this means they will use many different hose connector standards. In such cases, it is recommended that you prepare sufficient inventory for selection. Two-piece connectors are undoubtedly the preferred option. As an after-sales maintenance service provider or equipment supplier, the factors you need to consider include: installation time, downtime, whether replacing the hose connector components can provide the same service life, and worker safety, etc.

У заключэнне

In conclusion, the key to choosing between two-piece or one-piece hose fittings lies in having a deep understanding of the requirements of the hydraulic system. We have discussed the main differences between the two, including the adaptability and customizability of the two-piece fittings versus the strength and leak-proofing of the one-piece design. Choosing the appropriate fittings is crucial for ensuring the efficiency, reliability, and durability of the system. One must weigh factors such as application pressure, environmental challenges, and the need for flexibility or simplicity. I encourage readers to carefully consider these two options based on their specific system requirements, ensuring that the chosen solution is both in line with current and long-term operational goals. Making a wise choice not only optimizes the performance of the hydraulic system but also enhances its overall productivity and durability.

Delve deeper into our knowledge base to obtain expert advice, innovative solutions, and industry-leading best practices, all of which can help improve the performance of your hydraulic system. If you have any questions or are ready to place an order, please contact us directly. Our team is more than happy to help you find the perfect solution that meets your specific needs.

Are you ready to source your hydraulic fittings? Синопульс offers a wide variety of high-quality one-piece and two-piece fittings with highly competitive wholesale prices. Please contact us immediately to discuss your needs and obtain quotations!

FAQ about hose fittings

Q1: What are the main advantages of One-piece fittings?

Answer: The One-piece fittings is simple in design, easy to install, has a low risk of leakage, and has a lower overall maintenance cost. Its design aims to provide a safe and reliable connection and complies with various industrial standards.

Q2: How are One-piece fittings different from the Two-piece fittings?

Answer: Although both have their own uses, the One-piece fittings is generally easier to install and maintain due to its integrated design. Compared to the two-piece hydraulic hose fittings, it has fewer potential failure points and is therefore a better choice in critical applications.

Q3: Which material is the most suitable for corrosive environments?

Answer: The stainless steel One-piece fittings is an ideal choice for corrosive environments due to its excellent oxidation resistance and chemical corrosion resistance. However, the specific selection may vary depending on the environmental conditions and application requirements.

Q4: What standards should be considered when purchasing hose connectors?

Answer: Select hose fittings that comply with industry standards (such as DIN, ISO, JIC and BSP). These certifications ensure that the manufacturing of the fittings meets strict quality and performance standards.

Q5: How can I ensure compatibility with my hydraulic system?

Answer: It is essential to verify the thread specifications, pressure rating and material specifications of the fitting. Consulting an experienced manufacturer of hose fittings can help you select the appropriate product based on the specific requirements of the system.