Hydraulic connections are used in hydraulic systems to connect hoses, pipes and other components, ensuring a secure and reliable connection and preventing leaks. However, there are numerous types and various sizes of hydraulic connections, making the selection of the appropriate one not an easy task. This guide will help you understand their types and how to choose them.

Змест

Пераключыць

What is Hydraulic Connection?

The hydraulic system uses the properties of pressurized fluid to transfer mechanical energy. The energy is transferred from one point to another through the fluid within the hydraulic hose, and the hydraulic hose is connected to the mechanical equipment using hydraulic fittings connectors.

The hydraulic connector must be firmly attach to the equipment and the hose, and withstand high pressure and high temperature. The connectors come in various sizes, materials, sealing types and have different temperature and pressure tolerances.

Some connectors allow fluid to flow, some prevent fluid from flowing, and some are designed to do both. The most important function of a connector is to form a tight seal to prevent fluid leakage and the entry of contaminants.

Types of Hydraulic Connection

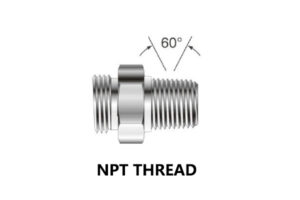

American Connections

The NPT (National Pipe Thread) pipe thread has been widely used for over 100 years. NPT is the standard for tapered threads in the United States and is used for pipes and pipe fittings. They are used for effectively sealing fluid and gas transfer. The nominal pipe diameter can be identified by measuring the thread diameter and then subtracting 1/4 inch.

available in iron or brass, and they are suitable for low-pressure applications; and there are also carbon steel and stainless steel types, suitable for high-pressure applications.

The NPTF (National Pipe Tapered Fuel) connection is widely used in fluid power systems. Its tapered thread achieve sealing through thread deformation. The method for measuring the size of the NPTF thread is: measure the thread diameter, then subtract 1/4 inch, and you will get the nominal pipe size.

The NPSM (National Pipe Straight Mechanical) connections are also commonly used in fluid power systems. The female component adopts straight threads and has a 30° seat. The male male component also uses straight threads and has a 30° internal chamfer. The seal is achieved through the compression of the 30° chamfer against the internal chamfer. This is a mechanical connection. If the NPTF male appropriate chamfering treatment, it can also achieve sealing with the NPSM female connection.

The National Fire Protection Association (N.F.P.A.) recommends the use of SAE J1926 straight thread O-ring boss (ORB) to prevent leakage in medium and high-pressure hydraulic systems. The male connection is a straight thread with an O-ring. The female port is also a straight thread and has been machined to form a smooth and flat surface (minimum spotface) as well as a chamfer where the O-ring seats. When the O-ring is compressed into the chamfer, the male connection and the female connection can be matched to achieve sealing. This is also considered a mechanical connection.

The SAE J514 JIC/37° hydraulic сувязі is very common in most fluid power systems. Both the male connector and the female connector feature a 37° seats. The seal is achieved through the contact between the male flared and female coned seat. This is also regarded as a mechanical connection.

The SAE J512 45° connections is widely used in automotive, refrigeration and truck piping systems. These connectors are typically made of brass. Both the male joint and the female joint adopt a 45° angle seats design. The sealing function make where the male flare and the female cone meet. This is a mechanical connection.

NOTE dash sizes: -02, -03, -04, -05, -08, and -10 of SAE 37° and SAE 45° have the same threads, but NOT the same seat angles. Intermixing the two different types of fittings will result in leakage, so use care in measuring seat angles.

The O-ring Face Seal connections as per SAE J1453 (ORFS) is regarded as the best for leakage control. The male connector uses straight threads and has an O-ring on its face. The female connector also uses straight threads and has a machined flat surface on its flat face. The sealing principle is achieved by pressing the O-ring onto the flat surface of the female connector, similar to a split flange connector. The threads maintain the connection mechanically.

The SAE J512 Inverted connection is commonly used in automotive systems. The male connector has a 45° flared opening inside the pipe connector, or a 42° threaded seat in a machined adapter. The female connector uses straight threads and has a 42° inverted flare opening. The connector seals at the flared surface. These threads also maintain the mechanical connection.

SAE J518 4-bolt Flange, This connection has two pressure ratings: the standard series is Code 61, and the 6000 PSI series is Code 62. The designs of the two series are the same, but the flange head diameter and bolt hole spacing of the 6000 PSI high-pressure Code 62 connection are larger.

The female port of the connection is a smooth, unthreaded port, and the four bolt holes are arranged in a rectangular pattern around the port. The male port is a head with a flange, featuring a groove for O-rings, and the flange can be split or integral, with the bolt holes matching the port. The seal is achieved by compressing the O-ring between the flange head and the port plane. The connection is fixed by threaded bolts.

*Except for bolt size, the SAE J518, JIS B 8363, ISO/DIS 6162, and DIN 20066 standards can be interchanged.

British Connections

The Брытанская стандартная труба (BSP) and BSPT (tapered) connections are similar to NPT connections, but the pitch of most sizes is different. Although the outer diameters and thread form are similar, they are not exactly the same. Sealing is achieved through the deformation of the threads. Therefore, it is recommended to use thread sealant when securing these connections.

BSPP (Parallel) The BSPP male connector is similar to the NPSM male connector, except that the pitch of most sizes is different. Its sealing method is a metal-on-metal inclined surface contact, or a combination of metal-on-metal contact with an O-ring. This connection method is very similar to the American NPSM male connector (but not interchangeable). The BSPP female connector is an tapered nose flareless swivel, and the sealing occurs on the cone seat of the male connector.

German Connections

The DIN 7631 series are common metric connectors used in hydraulic systems. The male connector uses straight threads, with a recessed cone surface at a 60° angle. The female connector also uses straight threads, with a tapered nose seat. The tapered nose surface of the male connector contacts the flareless swivel of the female connector to form a seal.

The DIN 2353/ISO 8434 series is a common male thread with three different female halves. The inclination angle of this straight metric thread external thread is 24°. Its counter-bore matches the outer diameter of the connected pipe. The female thread can be one of the following types:

tube, nut and ferrule (compression type)

tapered nose flareless swivel

tapered nose flareless swivel with a DKO style O-ring in the nose

DIN 3902: Offers various female connection options like compression and flareless swivel. The male part has a 24° angle, and some female options may include O-rings.

DIN 3852: DIN 3852 fittings are a popular choice in hydraulic applications globally, setting a standard for connector and port designs. Their versatility makes them compatible with various hose sizes and metric threads.

Japanese Connections

JIS Tapered Pipe (PT) adopts metric threads that comply with the JIS B 0203 standard. These are JIS tapered threads are comparable to the design of BSPT connections. JIS conical thread connections can be interchanged with BSPT connections.

The JIS 30° Male Inverted Seat connection is a parallel pipe thread in accordance with the JIS B 0202 standard. The JIS parallel connection is equivalent to the BSPP connection. The JIS parallel thread connection can be interchanged with the BSPP connection.

The JIS 30° Female (Cone) seat complies with the JIS B 0202 standard and belongs to the parallel pipe thread. The Japanese JIS 30° flared connection is similar to the American SAE 37° flared connection in terms of application and sealing principle. However, the angle and size of the JIS 30° flaring are different, and its thread is similar to the BSPP thread.

JIS B 8363 4-Bolt Flange connections are frequently used in fluid power systems. There are two pressure ratings for JIS B 8363 4-Bolt Flange fittings:

1) Type I Code 61 is the standard series 4-Bolt Flange

2) Type II Code 62 is the 6000 PSI series

AN Connections

AN (Army-navy)hydraulic fittings are flared fittings with a 37-degree angle to create a metal seal. This type of fitting is mainly used to connect hoses and metal pipes. It is similar to JIS hydraulic fittings and is theoretically universal, but it is not recommended and used interchangeably

ISO Connections

ISO/DIS 6162 4-bolt Flange is a common connection method in fluid power systems. This connection method has two pressure ratings: the standard series is 61 type, with PN 35/350 bar; the high-pressure series is 62 type, with PN 415 bar. Their structures are the same, but the bolt hole spacing and flange head diameter of the high-pressure series PN 415 bar are larger. These connection methods can use either imperial or metric bolts. If metric bolts are used, the port will be marked with "M". The inner port of the joint is a smooth, unthreaded port, with four bolt holes arranged in a rectangular pattern around it. The outer port is a flange head, with a groove for accommodating O-rings. The flange is available in split and integral types, and the bolt holes match the inner port. The seal is achieved by compressing the O-ring between the flange head and the port plane. The connection is fixed by threaded bolts.

ISO 6149 Port and Stud Ends with ISO 261 Threads and O-ring Seal. Although it is similar to the SAE J514 straight-thread O-ring Boss (ORB), this connection method uses metric threads. The male connector has a straight thread and an O-ring. The female port also has a straight thread, with its surface precisely machined to form a smooth, flat, and accurately located surface (minimum point surface), and it has chamfers for accommodating the O-ring. When the O-ring is pushed into the chamfer, the male joint and the female joint mate, achieving sealing. This connection method is also regarded as a mechanical connection.

How to Choose the Right Hydraulic Connector

Selecting the appropriate hydraulic connectors is of vital importance for ensuring the safety and efficiency of the hydraulic system. The following are the key factors that need to be considered. Some of these considerations are summarized as a STAMP acronym:

This refers to the памер and the thread type of the fitting. It should seamlessly match the hose or tubing you’re connecting. Common sizing standards include NPT, BSP, and metric (ISO), which are described above.

It is essential to consider both the working temperature of the system and the temperature of the environment where the joint will be used. Some materials may become brittle or lose strength at extreme temperatures.

Consider the function of the connection in the system прымяненне. It may be necessary to use a joint specifically designed to handle high-vibration environments, while quick-connect options may be suitable for easy assembly and disassembly.

Related to the application, how will the fitting be attached to the hose or tubing? Crimped fittings are permanent and durable, while reusable fittings are more flexible.

Material: The material of the joint needs to be compatible with the hydraulic oil used and be able to withstand the pressure of the system.

Pressure: The rated pressure of the joint must be greater than the maximum pressure generated by the hydraulic system. Choosing a joint with a pressure lower than the system's maximum pressure may lead to catastrophic failures.

Fluid: Different fluids have varying properties, which may affect the choice of fitting material. The fluid must be compatible with the fitting material to avoid corrosion or degradation.

By carefully evaluating these factors, you can select the most suitable hydraulic connector for your application. If you have any doubts about the selection process, it is recommended that you consult a hydraulic expert, especially in cases where the system is complex.

Hydraulic hose connection expert

Do you need assistance with гідраўлічныя раздымы? The hydraulic experts department of SINOPULSE is always available to provide support for you. Whether you need to know which connector is the most suitable for your application, or you need a complete hydraulic system design, our professionals will offer you the best solution.

We have an inventory of industrial hoses and connectors worth over one million US dollars. We produce over ten million parts per day and can meet all your needs.

Звяжыцеся з намі to learn more about our hydraulic systems, accessory services and products.