Wąż hydrauliczny jest kluczowym elementem układów hydraulicznych. Przenosi on energię hydrauliczną w maszynach i urządzeniach. Jest zaprojektowany do pracy pod ekstremalnie wysokim ciśnieniem. Może on skutecznie transportować płyny hydrauliczne między różnymi elementami, takimi jak pompy, zawory, cylindry i silniki.

Części węży hydraulicznych

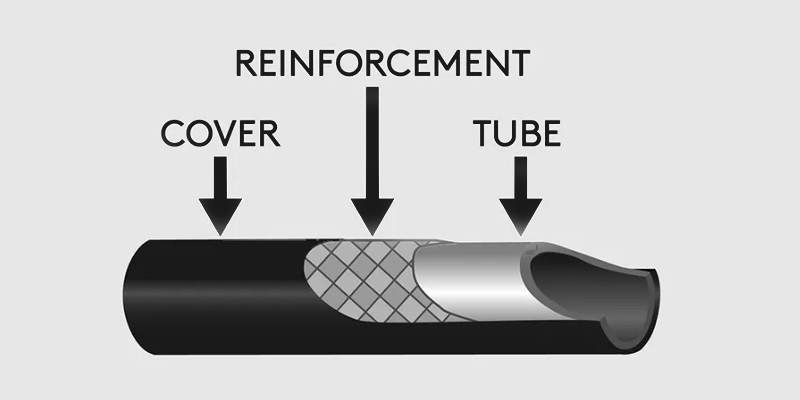

Wąż hydrauliczny jest specjalnie zaprojektowany do układów hydraulicznych. Przewodzi on olej lub wodę pod wysokim ciśnieniem z pomp do siłowników. To właśnie w siłownikach ten płyn jest wykorzystywany do generowania ruchu mechanicznego. Wąż składa się z trzech różnych części: rury wewnętrznej, warstwy wzmacniającej i osłony zewnętrznej. Poniżej przedstawimy szczegółowo te trzy części, aby lepiej zrozumieć działanie węży hydraulicznych.

Część rurowa

Rurka to wewnętrzny rdzeń węża, którym płynie ciecz z jednego końca węża na drugi. Musi być elastyczna. Jest to szczególnie istotne w przypadku urządzeń z elastycznymi złączami. Ponadto wąż musi być kompatybilny z cieczą, którą transportuje.

Poniżej wymieniono różne rodzaje płynów hydraulicznych:

Płyn na bazie ropy naftowej: Chroni przed zużyciem, utlenianiem, korozją i ekstremalnym ciśnieniem.

Płyn na bazie wody: Stosowany ze względu na wysoką zawartość wody, jako materiał ognioodporny.

Płyn na bazie syntetycznej: Zapewnia ognioodporność, niskie tarcie, stabilność termiczną i nadaje się do zastosowań w wysokich temperaturach i przy wysokim ciśnieniu.

Materiał dętki zwykle zawiera tworzywo termoplastyczne, gumę syntetyczną i politetrafluoroetylen (PTFE), aby zapewnić odporność na korozję i działanie substancji chemicznych.

Do stosowanych tworzyw termoplastycznych należą zazwyczaj poliamid, poliester, a nawet fluoropolimery. Wszystkie te materiały charakteryzują się wysoką odpornością na rozpuszczalniki, kwasy i zasady.

Kauczuki syntetyczne: Doskonała elastyczność.

Fluoropolymery: Doskonała odporność chemiczna i odporność na korozję, stabilna praca w wysokich temperaturach i długi okres przydatności do użycia.

Tworzywa termoplastyczne: Obsługuje mniejsze minimalne promienie gięcia, zapewniając jednocześnie doskonałą odporność na zginanie i splątywanie.

Część wzmacniająca

To właśnie decyduje o trwałości węża hydraulicznego. Wzmocnienie określa ciśnienie robocze węża. Wytrzymałość ciśnieniowa węża hydraulicznego jest jego cechą charakterystyczną. W związku z tym wymagane ciśnienie robocze bezpośrednio determinuje konstrukcję węża. Im więcej warstw wzmocnienia, tym wyższa wartość ciśnienia. Zazwyczaj występuje ono w konfiguracji plecionej, spiralnej lub śrubowej. Struktury te są wykonane z pojedynczej lub wielu warstw wzmocnienia z plecionego drutu stalowego, przędzy tekstylnej lub spiralnego drutu stalowego.

A spiralny wąż hydrauliczny Wąż ten wykorzystuje cztery lub więcej warstw spiralnie zwiniętego, wysokowytrzymałego drutu stalowego. Taka konstrukcja sprawia, że wąż jest bardzo wytrzymały, ale jednocześnie dość sztywny. Z tego powodu jego elastyczność jest ograniczona. Został zaprojektowany specjalnie do zastosowań w ekstremalnie wysokich ciśnieniach. Zazwyczaj można go znaleźć w sprzęcie budowlanym i ciężkich pojazdach terenowych.

Wąż Multi-Spiral został zaprojektowany z wieloma warstwami wzmocnienia, co zapewnia maksymalną wytrzymałość i trwałość. Jego unikalna spiralna konstrukcja zapewnia większą elastyczność bez uszczerbku dla wydajności. Niezależnie od tego, czy masz do czynienia z ciężkim sprzętem, czy wymagającymi zastosowaniami przemysłowymi, ten wąż poradzi sobie ze wszystkim.

Wąż pleciony Składa się z dętki z syntetycznej lub naturalnej gumy, wzmocnionej jedną lub kilkoma warstwami plecionego materiału tekstylnego lub drutu stalowego. Zapewnia doskonałą elastyczność i wysoką odporność na ścieranie.

Jeśli chodzi o niezawodne i trwałe węże, węże w oplocie to najlepszy wybór. Te wszechstronne węże zyskały popularność w różnych branżach dzięki wyjątkowej wytrzymałości i elastyczności.

Wąż hydrauliczny w oplocie jest bardziej elastyczny niż wąż spiralny, co zapewnia węższy promień skrętu i dobrą elastyczność. Węże w oplocie są szeroko stosowane w takich branżach jak produkcja, budownictwo, motoryzacja, lotnictwo i inne. Znajdują zastosowanie w transporcie płynów, takich jak woda, ropa naftowa, gaz, chemikalia, przy jednoczesnym zachowaniu optymalnego natężenia przepływu i zapobieganiu wyciekom lub pęknięciom.

Węże śrubowe Oferują największą elastyczność, a ich struktura zapobiega zapadaniu się pod wpływem podciśnienia, zapewniając lepszą odporność na obciążenia udarowe niż węże plecione. Spirale nie zachodzą na siebie, co zapobiega zużyciu poprzez tarcie o siebie, co przekłada się na lepszą odporność na obciążenia impulsowe niż w przypadku węży z oplotem. Zastosowania węży powrotnych, które mogłyby zapadać się zarówno w węże plecione, jak i spiralne, na siebie.

Część okładki

Osłona chroni zbrojenie i rurę przed wpływem czynników zewnętrznych. Jest ona zaprojektowana jako rura odporna na ścieranie, ozon i olej oraz działanie czynników atmosferycznych. Zazwyczaj jest wykonana z gumy syntetycznej i/lub tworzywa sztucznego – zazwyczaj poliuretanu (PUR). Powodem popularności PUR jest jego doskonała odporność na ścieranie i uderzenia. Jest to również idealny materiał na osłonę węża ze względu na odporność na wibracje. Używana guma syntetyczna to zazwyczaj neopren, który również oferuje doskonałą odporność na ścieranie. Może być stosowana w szerokim zakresie temperatur, ale ma krótszy okres trwałości niż PUR i nie jest tak elastyczna.