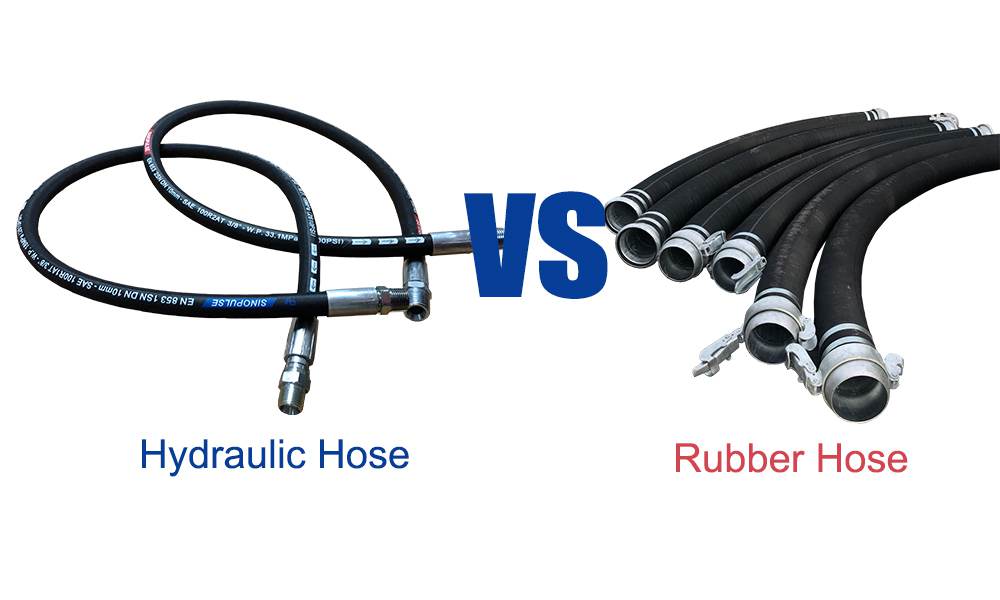

Kauçuk hortumlar ve kauçuk Hidrolik hortumlar Görünüşte benzer olsalar da farklı uygulamalarda kullanılırlar. Kauçuk hortumlar bahçelerde kullanılırken, hidrolik hortumlar büyük ekipmanlarda kullanılır. Bu makale, ihtiyaçlarınıza uygun hortumu seçmenize yardımcı olmak için aralarındaki farkları anlatacaktır.

Nelerdir? Hidrolik hortumlar?

Hidrolik hortumlar, buldozer ve vinç gibi makinelerde hareketli parçalar ve işletme ekipmanları için yaygın olarak kullanılır. Hidrolik sıvıyı yüksek basınç altında yırtılmadan taşırlar. Mukavemet ve güvenliği artırmak için çoğunlukla çelik tel ve fiber ipliklerle güçlendirildikleri için çok güçlüdürler ve büyük ekipmanların sorunsuz ve güvenli çalışmasını sağlarlar.

Nedir? kauçuk hortum?

Kauçuk hortumlar öncelikle hava, su ve yağ gibi çeşitli maddeleri taşımak için kullanılır. Kauçuktan üretilen bu hortumlar, kırılmadan bükülüp kıvrılabildiği için bahçelerden benzin istasyonlarına kadar farklı tipte kauçuk hortumlar kullanılmaktadır. Kauçuk hortumlar, farklı uygulamaların ihtiyaçlarını karşılamak için birçok boyut ve türde mevcuttur.

Hidrolik Hortum mu, Kauçuk Hortum mu?

Yapı

Kauçuk hortumlar, çoğunlukla sentetik ve doğal kauçuktan üretilir ve yüksek esneklik ile çeşitli bükülme ve ince kıvrımlara uyum sağlar. Dar alanlardaki engellerin etrafından kolayca geçebilirler. Bahçe su boruları ve hava kompresörü hortumları gibi konut ve ticari alanlarda kullanılırlar. Ayrıca hava, su, yağ ve kimyasallar gibi malzemelerin taşınması ve üretiminde de kullanılırlar.

Hidrolik hortumlar çok katmanlı bir yapıya sahiptir. İç katman termoplastik ve sentetik kauçuktan oluşurken, orta katman çelik tel ve elyafla güçlendirilmiştir. Örgü veya sarma teknikleri, hidrolik hortumun basınç direncini ve mukavemetini artırır. Dış katman ise hortumu aşınmaya ve yağ ve kimyasallar gibi çevresel hasarlara karşı korur.

Basınç

Farklı hortumlar farklı basınçlara dayanabilir. Kauçuk hortumlar nispeten düşük basınca, genellikle düşük ila orta basınca dayanabilir. Çalışma basıncının aşılması patlama ve hasar riski taşır. Bu nedenle kauçuk hortumlar, bahçelerde ve evlerde düşük ila orta basınçlı uygulamalarda yaygın olarak kullanılır. Düşük basınca dayanmaları gerekse de, esneklikleri ve kullanım kolaylıkları onları bu görevler için ideal kılar.

Hidrolik hortumlar çok daha yüksek basınçlara dayanacak şekilde tasarlanmıştır. Çok katmanlı malzeme yapıları, buldozer, ekskavatör ve hatta uçak gibi büyük makinelerdeki hidrolik sistemlerin yüksek basınçlarına dayanabilir. Hidrolik sıvının hidrolik sistemin çeşitli parçalarına yüksek basınçla iletilmesi, inşaat ekipmanlarından hidrolik asansörlere kadar çeşitli ekipmanların yüksek basınç koşullarında güvenli ve verimli çalışmasını sağlar.

Uygulamalar

Kauçuk hortumlar geniş bir uygulama alanına sahiptir ve çeşitli durumlar için uygundur. Evlerde ve bahçelerde yaygın olarak kullanılırlar, bitkileri sulamada veya çamaşır makineleri gibi ev aletlerinin bir parçası olarak hayati bir rol oynarlar. Otomotiv endüstrisinde kauçuk hortumlar, otomobil ve kamyonların soğutma ve emme sistemleri için olmazsa olmazdır. Fabrikalar da, özellikle aşırı basıncın gerekli olmadığı hava veya su iletimi için kauçuk hortumlara güvenir. Esnekliği ve temel basınca dayanma kabiliyeti, kauçuk hortumları günlük işlerde vazgeçilmez bir araç haline getirir.

Hidrolik hortumlar yüksek basınç direncine ve mukavemete sahiptir. İnşaat sektöründe hidrolik hortumlar, ağır nesnelerin kaldırılması ve taşınmasında yardımcı olmak için kullanılan buldozer ve ekskavatör gibi ağır ekipmanların vazgeçilmez bir parçasıdır. Tarımda ise hasat ve diğer işlemleri kolaylaştırmak için tarım ekipmanlarında hidrolik hortumlar kullanılır. Üretim makineleri, malzemeleri preslemek, bükmek veya şekillendirmek için hassas ve güçlü hareketler gerektirir ve bu nedenle hidrolik hortumların mukavemetine büyük ölçüde bağımlıdır. Ayrıca, hidrolik hortumlar havacılık ve denizcilik sektörlerinde uçak ve gemilerin dümen ve kanatçıklarını kontrol etmek için hayati bir rol oynar. Hidrolik hortumların yüksek basınca dayanma kabiliyeti, bu ağır hizmet tipi ve yüksek hassasiyetli uygulamalarda kullanımlarının anahtarıdır.

Maliyet

Kauçuk hortumlar, ana bileşenleri kauçuk olduğundan hidrolik hortumlardan daha ucuzdur ve bu da daha düşük üretim maliyetleri sağlar. Hidrolik hortumlar, yüksek basınçlı ve ağır hizmet uygulamaları için tasarlanmıştır ve bu nedenle daha pahalıdır. Bunun nedeni, sağlam bir yapıya sahip olmaları ve yüksek performansları için hayati önem taşıyan çelik tel gibi malzemelerle güçlendirilmiş olmalarıdır. Arıza sürelerinin yüksek olduğu, mukavemet ve dayanıklılığın gerekli olduğu nötr ekipmanlar için hidrolik hortumlar daha iyi bir seçimdir.

Hidrolik hortum veya kauçuk hortum seçin.

Uygulamalar

Evinizde bir proje üzerinde çalışıyorsanız veya bitkileri sulamak gibi hafif bir iş yapıyorsanız, kauçuk hortumlar ideal olabilir. Bu hortumlar esnektir ve düşük basınç gerektiren işler için mükemmeldir. Ancak, ağır makine çalıştırıyorsanız veya inşaat ya da imalat gibi endüstriyel operasyonlar için hortumlara ihtiyacınız varsa, hidrolik hortumlar daha iyi bir seçimdir. Bu hortumlar zorlu ortamlar için tasarlanmıştır ve yüksek basınca kolayca dayanabilir.

Basınç

İş için gereken basıncı her zaman göz önünde bulundurun. Kauçuk hortumlar, hidrolik hortumların kaldırabileceği yüksek basınçlara dayanamaz. Ayrıca taşınan ortamı da göz önünde bulundurun. Sadece su veya hava ise, kauçuk hortum yeterli olabilir. Ancak yağ veya diğer kimyasallar söz konusuysa, hidrolik hortumun gücüne ihtiyacınız olabilir.

Ortamlar

Hidrolik sistem için özel olarak tasarlanmış bir hortuma ihtiyacınız varsa ve hidrolik yağı veya sentetik yağlar gibi hidrolik sıvıları taşıyorsanız, bir hidrolik hortum seçin. Kauçuk hortumlar, özellikle zorlu ortamlarda su, hava veya kimyasallar dahil olmak üzere çok çeşitli sıvıları taşıyabilir.

Sıcaklık

Standart hidrolik hortumlar -40°C ile 100°C arasında çalışır ve bu sayede soğuk iklimler de dahil olmak üzere çoğu bölge için uygundur. Kauçuk hortumların sıcaklık aralığı, malzemelerine göre belirlenir ve yaygın kauçuk hortumlar genellikle -20°C ile 80°C arasında çalışır.

Uzunluk ve Bükülme Yarıçapı

Hortumun iç ve dış çaplarını ve toplam uzunluk gereksinimlerini göz önünde bulundurun.

Bağlayıcılar

Hortumun her iki ucundaki gerekli konnektörleri göz önünde bulundurun. Bu konnektörler hidrolik sisteminize ve kullanabileceğiniz herhangi bir sıvı depolama kabına bağlanmalıdır.

Sertifikalar

Hidrolik hortumlar genellikle yüksek basınç ve yüksek darbeli uygulamalarda kullanılır, bu nedenle standartları dayanıklılık ve performansa odaklanır. Başlıca standart sistemleri SAE, ISO ve EN'dir.

Industrial rubber hoses have a wider range of applications and require more extensive certifications. For example, FDA sertifikası is required for conveying food and drinking water. Steam conveying requires heat and pressure resistance.

SSS

Kauçuk hortumlar ile hidrolik hortumlar arasındaki temel farklar nelerdir?

Kauçuk hortumlar esnektir ve bahçe işleri veya gaz temini gibi düşük ve orta basınç uygulamaları için uygundur. Hidrolik hortumlar ise daha sağlam yapıları ve çok katmanlı yapıları nedeniyle ağır makineler gibi yüksek basınç uygulamaları için tasarlanmıştır.

Kauçuk hortumlar her türlü yüksek basınç işleminde kullanılabilir mi?

Hayır, kauçuk hortumlar yüksek basınçlı ortamlar için uygun değildir. Düşük basınçlı uygulamalar için tasarlanmıştır. Yüksek basınç gereksinimleri için, daha sağlam yapıları nedeniyle hidrolik hortumlar daha iyi bir seçimdir.

Kauçuk hortumlar ve hidrolik hortumlar genellikle ne kadar dayanır?

Kauçuk hortumların ve hidrolik hortumların ömrü, kullanım ve bakıma bağlıdır. Hafif hizmet uygulamalarında kauçuk hortumlar birkaç yıl dayanabilirken, endüstriyel ortamlarda hidrolik hortumlar uygun bakımla daha da uzun süre dayanabilir.

Hidrolik hortumlar kauçuk hortumlardan daha mı pahalıdır?

Evet, genel olarak hidrolik hortumlar kauçuk hortumlardan daha pahalıdır çünkü yapıları ve malzemeleri daha karmaşıktır, daha yüksek basınçlara ve daha zorlu koşullara dayanacak şekilde tasarlanmıştır.

Hidrolik hortumlar sıradan kauçuk hortumların yerini alabilir mi?

Teknik olarak mümkün olsa da, bunu yapmak ne ekonomik ne de pratiktir. Hidrolik hortumlar endüstriyel uygulamalar için tasarlanmıştır ve sıradan ev kullanımı için çok dayanıklı ve pahalı olabilir. Kauçuk hortumlar ise çoğu ihtiyaç için yeterlidir.

Hangi kauçuk hortum malzemesi kimyasallara karşı daha dayanıklıdır?

Petrol bazlı sıvı ve yağların taşınması için NBR veya FKM hortumlar iyi birer seçenektir. Su ve buhar gibi yağsız ortamların taşınması içinse EPDM kauçuk hortumlar iyi birer seçenektir.

Hortumların bakımı nasıl yapılır?

Doğru hortum bakımı, kullanım ömürlerinin uzamasına yardımcı olur. Hortumun durumunu çatlak ve aşınma açısından düzenli olarak kontrol etmelisiniz. Hortum bağlantılarında gevşeklik ve sızıntı olup olmadığını kontrol edin. Ayrıca, montaj talimatlarına uygun olarak düzenli temizlik de gereklidir.

Hidrolik hortumlar kauçuk mudur?

Kauçuk hidrolik hortumlar en yaygın kullanılanlardır, ancak termoplastik hidrolik hortumlar ve PTFE hidrolik hortumlar da aşırı yüksek basınçlı ve yüksek aşındırıcı ortamlarda yaygın olarak kullanılır.

Hidrolik hortum seçerken STAMPED standardını takip eder ve iç ve dış katman malzemelerini göz önünde bulundurursanız, güvenilir kauçuk hortumlar ve hidrolik hortumlar elde edersiniz. Hidrolik hortumları nasıl seçeceğinizden emin değilseniz, lütfen profesyonel bir tedarikçi seçin ve Sinopülseİhtiyaçlarınıza en uygun hortumu seçmenizde yardımcı olur.