Manguera hidráulica EN 856 4SP

Hydraulic Hoses EN 856 4SP | High Pressure

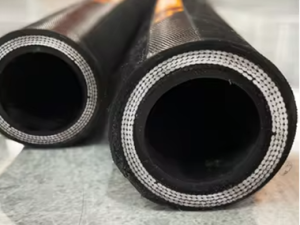

EN 856 4SP hose is a high-pressure hydraulic hose with four-wire spiral reinforcement designed to handle extreme conditions and provide reliable performance in heavy machinery applications.

EN 856 4SP hose is a multispiral hydraulic hose. It is suitable for outdoor applications like forestry and mine equipment. The hose is resistant to flame, static and abrasion resistance and impulse fatigue. Similar to EN 856 4SH hydraulic hose, EN 856 4SP hose has a higher working pressure under the same working temperature. It is composed of three parts: tube, reinforcement and cover. The tube is made from caucho sintético resistente al aceite, making the hose resistant to abrasion and corrosion and deliver petroleum-based hydraulic fuids easily within -40°F to +212°F. The reinforcement is made from four layers of high tensile steel wire spiral reinforcement, providing it with the strength and durability needed to withstand high pressures up to 6000 psi. The cover is made from abrasion and ozone resistant synthetic rubber, making the hose resistant to abrasion, corrosion and aging, accepted by MSHA

Hydraulic Hose DIN EN 856 4SP is designed for very high-pressure applications using petroleum-based hydraulic fluids. This high-quality hydraulic hose meets the stringent requirements of the DIN EN 856 4SP standard, ensuring reliable performance and long service life in demanding applications. Its four spiral layers of high tensile steel wire construction and high-pressure rating make it ideal for use in high-pressure hydraulic lines ranging from 165 to 450 bar.

Estructura

Cámara de aire: High-quality black oil resistant synthetic rubber

Reforzamiento: Four spiral layers of high tensile steel wire

Compuesto de cobertura: Black abrasion, corrosion and oil resistant synthetic rubber, resistant to exposure to various environments, precipitation and UV radiation.

Característica

Rango de temperatura: -40'C To +125°C (-40°F To +230°F)

Solicitud: Very high-pressure applications are used for petroleum-based hydraulic fluids.

The Specification of EN 856 4SP Hydraulic Hose

| N.º de pieza | IDENTIFICACIÓN | sobredosis | WP | Presión arterial | BR | Peso | |||

| Estrellarse | Pulgada | mm | mm | MPa | PSI | MPa | PSI | mm | kilogramos/m |

| EN8564SP-04 | 1/4" | 6.4 | 18.0 | 45.0 | 6525 | 180 | 26100 | 150 | 0.620 |

| EN8564SP-06 | 3/8" | 9.5 | 20.8 | 44.5 | 6453 | 178 | 25810 | 180 | 0.730 |

| EN8564SP-08 | 1/2" | 12.7 | 24.0 | 41.5 | 6018 | 166 | 24070 | 230 | 0.900 |

| EN8564SP-10 | 5/8" | 15.9 | 27.6 | 35.0 | 5075 | 140 | 20300 | 250 | 1.130 |

| EN8564SP-12 | 3/4" | 19.1 | 31.8 | 35.0 | 5075 | 140 | 20300 | 300 | 1.480 |

| EN8564SP-16 | 1" | 25.4 | 39.7 | 28.0 | 4060 | 112 | 16240 | 340 | 1.980 |

| EN8564SP-20 | 1.1/4" | 31.8 | 50.8 | 21.0 | 3045 | 84 | 12180 | 460 | 2.910 |

| EN8564SP-24 | 1.1/2" | 38.1 | 57.2 | 18.5 | 2683 | 74 | 10730 | 560 | 3.430 |

| EN8564SP-32 | 2" | 50.8 | 69.8 | 16.5 | 2393 | 66 | 9570 | 660 | 4.890 |

Descargar

Catálogo de mangueras hidráulicas sinopulse

Fábrica Sinopulse

Materia prima:

Material de caucho importado de Vietnam y Tailandia

Alambre de acero de alta resistencia a la tracción de 2750 Mpa de la fábrica de primera clase de China

Productos de mangueras hidráulicas potentes, seguras y estables

Buena dispersabilidad, alta presión de apoyo y rendimiento de pulso superior.

Excelente resistencia al aceite, resistencia al calor y resistencia al envejecimiento.

Excelente resistencia a la flexión y a la fatiga.

Taller de fábrica:

Sinopulse is a 100% manufacturer of hydraulic hoses and industrial hoses, including all oilfields, agriculture, transportation, construction, mining, and forestry.

Producción diaria de 500.000 metros de mangueras, taller de 40.000 m²

40 líneas de producción, que incluyen máquinas de unión de alta velocidad, máquinas trenzadoras, máquinas espiraladoras de alta velocidad, máquinas industriales automáticas VP de Italia y equipos de prueba de laboratorio de series completas.

120 trabajadores calificados, 6 ingenieros con 2 asesores técnicos de compañías internacionales famosas, 2 departamentos de control de calidad y 2 gerentes de almacén son parte de nuestra encantadora gente.

50 especialistas en ventas y tres grupos de logística atienden a nuestros clientes de Italia, Alemania, Reino Unido, España, EE. UU., Canadá, Brasil, Argentina, Panamá, Perú, Chile, Vietnam, Indonesia, Australia y Rumania.

Laboratorio:

Nuestra fábrica cuenta con una gama completa de equipos de prueba de laboratorio. Contamos con avanzadas capacidades de laboratorio para realizar pruebas de calidad de productos y trabajos de investigación y desarrollo, garantizando así una calidad estable y excelente.

Después de comprar las materias primas, probamos cada lote para asegurarnos de que cumplan con los requisitos técnicos de nuestro producto.

Después de la producción, probamos cada manguera, su presión de funcionamiento y de rotura, y realizamos una prueba de pulso para cada pedido para garantizar que esté calificada como 100% después de salir de fábrica.

Nos esforzamos por ofrecer a nuestros clientes mangueras de primera calidad, haciendo todo lo posible para garantizar su calidad.

"¡Que nuestros usuarios finales se sientan cómodos en el uso y seguros al conducir!" es nuestro objetivo común.

Embalaje del producto:

1. Al embalar mangueras hidráulicas, cartones o cajas de madera según los requisitos del cliente.

2. Empacaremos la manguera después de finalizar la producción de la manguera.

3. Generalmente se utilizan bolsas tejidas y películas plásticas para el embalaje.

4. Se puede proporcionar un embalaje especial según las necesidades del cliente. El embalaje especial es una solicitud de los clientes de Edible ACC Ording.

Continuous Brand Layline Example

| SINOPULSE G4SP-06 EN 856 4SP 3/8" (DN10) W.P. 45MPA (6550 PSI) -XXXXX- |

Encuentra un proveedor de confianza fábrica de manguerasCualquier requerimiento o problema puede consultarnos en cualquier momento.

Productos populares

What is DIN EN 856 4sp

EN 856 4SP steel wire spiraled hydraulic hose is suitable for mine hydraulic support and the related equipment. The hose is resistant to flame and static. It is almost similar to EN 856 4SH steel wire spiraled hydraulic hose in structure, but it can bear higher working pressure than EN 856 4SH steel wire spiraled hydraulic hose under the same temperature. It is composed of three parts: tube, reinforcement and cover. The tube is made from black oil resistant synthetic rubber, making the hose resistant to abrasion and corrosion. The reinforcement is made from four layers of high tensile and high strength spiraled steel wire which is specially designed for rubber hose, making the hose perfectly resistant to high pressure. The cover is made from high quality black synthetic rubber, making the hose resistant to abrasion, corrosion, cut, weather, ozone, oil and aging. More importantly, the appearance is cloth surface rubber. Therefore, the hose has longer service life.

How to choose right 4SP hydraulic hose?

In order to buy a high-pressure hose 4 SP for hydraulics, you need to be aware of the operating conditions and the requirements of the equipment. We offer a wide range of such products, which differ in their parameters:

Nominal channel diameter. The indicators vary from model to model and range from 4 to 50 mm. According to this, the marking on the product indicates: Hose EN856 4SP D 12, 20, 50, etc.

Working pressure. This type of hose is designed for medium pressures ranging from 165 to 450 atmospheres, depending on the purpose of the product.

Burst pressure. For hoses with four windings, the maximum permissible pressure indicator within the hydraulic network is 660 to 1800 atmospheres.

Bending radius. This indicator increases with the increase in the diameter of the hose and ranges from 150 to 660 mm.

Working temperature. The permissible temperature range is from –40 to +100 degrees.

Outer and inner diameter. Indicators necessary to choose the right hose for a certain type of equipment. The size is also important when selecting high-pressure hose accessories: according to the catalog or individual order.

Where to use 4SP hydraulic hose?

EN 856 4SP hoses are used in ultra-high pressure hydraulic lines, specific devices with strong wear conditions, as well as dynamic oil circuits, petroleum derivatives and applications with water hammer.

In hydraulic systems resistant to extremely high pressure and harsh conditions, fuel, antifreeze applications, air and water, extremely low temperature applications

High-pressure hydraulic hoses have a wide range of uses. The main ones are:

Construction, road-specific equipment;

Agricultural machinery;

Municipal machinery and equipment;

Logging equipment;

Oil production and mining equipment;

Industrial equipment for production, other purposes, increased pressure in the hydraulic network.

What is the difference between 4SP and 4SH sleeves?

Hoses 4SP and 4SH have the same number of wire layers (4). However, despite the external similarity and comparability of the technical parameters, the SP version has a thinner outer layer and a smaller bending radius.

What is the design of the 4SP hose?

The internal rubber tube of the hose 4SP ensures the tightness of the hose, resistance to oils and other chemicals located inside the hose. The multi-layer metal frame (four layers in the 4SP RVD) protects against the influence of internal and external pressure and the weight of the transmitted fluid. The outer layer is made of a special rubber composition and protects against the influence of external factors (harsh environment, temperature, UV radiation, mechanical stress).

To ensure maximum strength, the metal frame is laid in multiple layers using the winding method, alternating with rubber layers.

Hoses with 4SP indexing are designed for medium pressures and can withstand pressures from 165 to 450 bar and operating temperatures from -40°C to +100°C.

Can 4sp be used in low temperature environments?

Yes, in hoses designed for use at extremely low temperatures (down to -50 ° C), the inner surface is made of specially selected synthetic rubbers or elastic polymers (nitrile rubber, etc.), in the latter case, elastic polymers are used, in addition to softness. Freeze resistance, greater resistance to chemically aggressive liquids.