EN 856 4SP Hydraulic Hose

Hydraulic Hoses EN 856 4SP | High Pressure

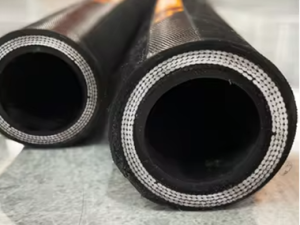

EN 856 4SP hose is a high-pressure hydraulic hose with four-wire spiral reinforcement designed to handle extreme conditions and provide reliable performance in heavy machinery applications.

The inner layer of the EN 856 4SP steel wire spiraled hydraulic hose is made of oil-resistant synthetic rubber, and four layers of high-strength steel wire are wrapped around the inner layer, with a protective layer of oil-resistant, weather-resistant, and abrasion.

The outer cover of the EN 856 4SP hose is made of oil, weather, and abrasion-resistant synthetic rubber, which protects the hose from external damage and maintains its flexibility in extreme conditions. This hose is capable of handling working pressures of up to 6000 psi (or 400 bar) and a temperature range of -40°C to +100°C (-40°F to +212°F).

Meets or exceeds the performance requirements of EN 856 4SP, DIN 20023 4SP, R9R

EN 856 4SP hoses are typically used in high-pressure hydraulic systems of heavy machinery, such as construction equipment, mining equipment, and industrial machinery.

Structure

Inner Tube: high quality black oil resistant synthetic rubber

Reinforcement: four layers of high tensile and high strength spiraled steel wire, with multiple layers of durable rubber between the steel wires.

Cover Compound: Black abrasion, corrosion and oil resistant synthetic rubber, resistant to exposure to various environments, precipitation and UV radiation.

Feature

Temperature Range: - 40ºC to + 125ºC.

Application: Very high-pressure applications are used for petroleum-based hydraulic fluids.

The Specification of EN 856 4SP Hydraulic Hose

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| EN8564SP-04 | 1/4" | 6.4 | 18.0 | 45.0 | 6525 | 180 | 26100 | 150 | 0.620 |

| EN8564SP-06 | 3/8" | 9.5 | 20.8 | 44.5 | 6453 | 178 | 25810 | 180 | 0.730 |

| EN8564SP-08 | 1/2" | 12.7 | 24.0 | 41.5 | 6018 | 166 | 24070 | 230 | 0.900 |

| EN8564SP-10 | 5/8" | 15.9 | 27.6 | 35.0 | 5075 | 140 | 20300 | 250 | 1.130 |

| EN8564SP-12 | 3/4" | 19.1 | 31.8 | 35.0 | 5075 | 140 | 20300 | 300 | 1.480 |

| EN8564SP-16 | 1" | 25.4 | 39.7 | 28.0 | 4060 | 112 | 16240 | 340 | 1.980 |

| EN8564SP-20 | 1.1/4" | 31.8 | 50.8 | 21.0 | 3045 | 84 | 12180 | 460 | 2.910 |

| EN8564SP-24 | 1.1/2" | 38.1 | 57.2 | 18.5 | 2683 | 74 | 10730 | 560 | 3.430 |

| EN8564SP-32 | 2" | 50.8 | 69.8 | 16.5 | 2393 | 66 | 9570 | 660 | 4.890 |

Sinopulse Factory

Raw Material:

Imported rubber material Vietnam and Thailand

High tensile strength 2750Mpa steel wire from China's first-class factory

Powerful, safe and stable hydraulic hose products

Good dispersibility, high bearing pressure and superior pulse performance.

Excellent oil resistance, heat resistance and aging resistance.

Excellent bending resistance and fatigue resistance

Factory Workshop:

Sinopulse is a 100% manufacturer of hydraulic hoses and industrial hoses, including all oilfields, agriculture, transportation, construction, mining, and forestry.

Daily output 500,000 meters of hoses, workshop covering 40,000 m²

40 production lines, involving high-speed joint machines, braiding machines, high-speed spiral machines, Italy VP automatic industrial machines, and Complete series Laboratory Testing Equipment

120 Skilled workers, 6 Engineers with 2 technical counselors from famous international companies,2 QC departments, and 2 warehouse managers are fall of our lovely people.

50 Sales and three groups of logistics specialists serve our clients from Italy, Germany, Uk, Spain, the USA, Canada, Brazil, Argentina, Panama, Peru, Chile, Viet Nam, Indonesia, Australia, Romania

Laboratory:

Our factory introduces a full range of laboratory testing equipment. It has advanced laboratory capabilities to conduct product quality testing and research and development work to ensure stable and excellent product quality.

After purchasing raw materials, we test each batch to ensure they meet our product's technical requirements.

After production, we test each hose, its working and burst pressure, and conduct a pulse test for each order to ensure that it is 100% qualified after leaving the factory.

We strive to provide our customers with top-notch hoses, doing everything we can to ensure their quality.

"Let our end users feel comfortable in use and safe in driving!" is our common goal.

Product packaging:

1. When packing hydraulic hoses, cartons or wooden boxes according to customer requirements.

2. We will pack the hose after finishing the hose production.

3. Generally, woven bags and plastic films are used for packaging.

4. Special packaging can be provided according to customer requirements. Special packaging is a request of Edible ACC Ording customers.

Continuous Brand Layline Example

| SINOPULSE G4SP-06 EN 856 4SP 3/8" (DN10) W.P. 45MPA (6550 PSI) -XXXXX- |

Find a trusted hose factory. Any requirements and problems can ask us at any time.

Hot Products

What is DIN EN 856 4sp

EN 856 4SP steel wire spiraled hydraulic hose is suitable for mine hydraulic support and the related equipment. The hose is resistant to flame and static. It is almost similar to EN 856 4SH steel wire spiraled hydraulic hose in structure, but it can bear higher working pressure than EN 856 4SH steel wire spiraled hydraulic hose under the same temperature. It is composed of three parts: tube, reinforcement and cover. The tube is made from black oil resistant synthetic rubber, making the hose resistant to abrasion and corrosion. The reinforcement is made from four layers of high tensile and high strength spiraled steel wire which is specially designed for rubber hose, making the hose perfectly resistant to high pressure. The cover is made from high quality black synthetic rubber, making the hose resistant to abrasion, corrosion, cut, weather, ozone, oil and aging. More importantly, the appearance is cloth surface rubber. Therefore, the hose has longer service life.

How to choose right 4SP hydraulic hose?

In order to buy a high-pressure hose 4 SP for hydraulics, you need to be aware of the operating conditions and the requirements of the equipment. We offer a wide range of such products, which differ in their parameters:

Nominal channel diameter. The indicators vary from model to model and range from 4 to 50 mm. According to this, the marking on the product indicates: Hose EN856 4SP D 12, 20, 50, etc.

Working pressure. This type of hose is designed for medium pressures ranging from 165 to 450 atmospheres, depending on the purpose of the product.

Burst pressure. For hoses with four windings, the maximum permissible pressure indicator within the hydraulic network is 660 to 1800 atmospheres.

Bending radius. This indicator increases with the increase in the diameter of the hose and ranges from 150 to 660 mm.

Working temperature. The permissible temperature range is from –40 to +100 degrees.

Outer and inner diameter. Indicators necessary to choose the right hose for a certain type of equipment. The size is also important when selecting high-pressure hose accessories: according to the catalog or individual order.

Where to use 4SP hydraulic hose?

EN 856 4SP hoses are used in ultra-high pressure hydraulic lines, specific devices with strong wear conditions, as well as dynamic oil circuits, petroleum derivatives and applications with water hammer.

In hydraulic systems resistant to extremely high pressure and harsh conditions, fuel, antifreeze applications, air and water, extremely low temperature applications

High-pressure hydraulic hoses have a wide range of uses. The main ones are:

Construction, road-specific equipment;

Agricultural machinery;

Municipal machinery and equipment;

Logging equipment;

Oil production and mining equipment;

Industrial equipment for production, other purposes, increased pressure in the hydraulic network.

What is the difference between 4SP and 4SH sleeves?

Hoses 4SP and 4SH have the same number of wire layers (4). However, despite the external similarity and comparability of the technical parameters, the SP version has a thinner outer layer and a smaller bending radius.

What is the design of the 4SP hose?

The internal rubber tube of the hose 4SP ensures the tightness of the hose, resistance to oils and other chemicals located inside the hose. The multi-layer metal frame (four layers in the 4SP RVD) protects against the influence of internal and external pressure and the weight of the transmitted fluid. The outer layer is made of a special rubber composition and protects against the influence of external factors (harsh environment, temperature, UV radiation, mechanical stress).

To ensure maximum strength, the metal frame is laid in multiple layers using the winding method, alternating with rubber layers.

Hoses with 4SP indexing are designed for medium pressures and can withstand pressures from 165 to 450 bar and operating temperatures from -40°C to +100°C.

Can 4sp be used in low temperature environments?

Yes, in hoses designed for use at extremely low temperatures (down to -50 ° C), the inner surface is made of specially selected synthetic rubbers or elastic polymers (nitrile rubber, etc.), in the latter case, elastic polymers are used, in addition to softness. Freeze resistance, greater resistance to chemically aggressive liquids.