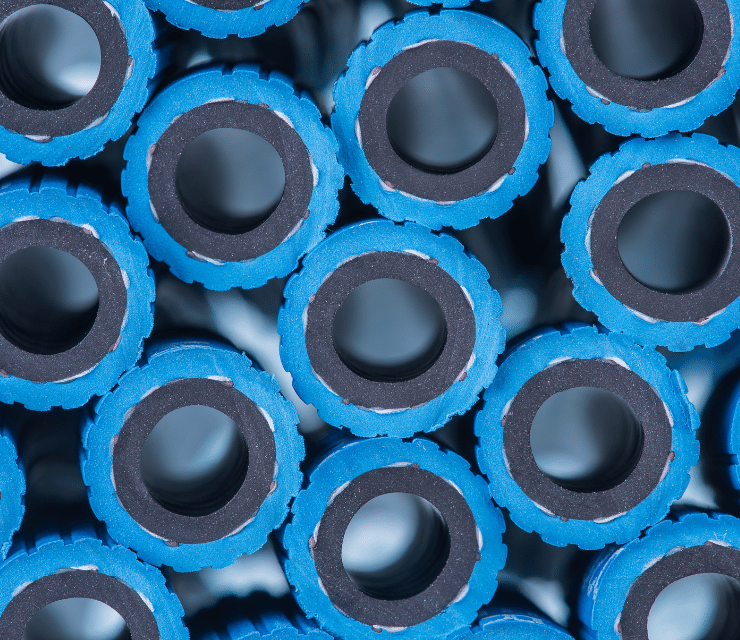

Textile Reinforced Hoses

Wire reinforced rubber hose is a type of hose that is reinforced with a textile material, such as nylon, polyester, or rayon. This type of hose is designed to be more durable and flexible than traditional rubber hoses. It is often used in applications requiring a higher pressure or temperature resistance level, such as in mines, quarries, construction, industrial air placement, sandblasting and rental equipment. The textile reinforcement helps to increase the hose's strength and flexibility while also providing additional protection against abrasion and other types of wear and tear. It is ideal hose for stainless steel concrete sprayers.

Our textile braided hose lets you count on seamless fluid transfer, even in challenging environments, with a rugged fabric braid reinforcement and oil-resistant synthetic rubber tube, reliable, flexible and durable hoses.

Designed to resist abrasion, these hoses are ideal for low-pressure lines and return lines. Black standard covers provide an extra layer of protection to ensure long-term durability.

Whether you are in the industrial, agricultural or construction fields, our textile braided hoses are for you. Their versatility, reliable fluid transfer and powerful performance improve overall equipment efficiency.

Tube: NR & SBR synthetic rubber.

Reinforcement: High tensile synthetic yarn braided or spiraled.

Cover: NR & SBR synthetic rubber.

Alias: Rubber Air hoses, Flexible Reinforced Air Hoses, reinforced air tubing.rubber air pipeline.

application:Good resistance to abrasion, ozone, sunlight and aging. Very flexible ...

Cover: Double braided black nylon

Reinforced: Stainless steel lined and reinforced synthetic rubber hose

Tube: Rubber

Application: For a variety of applications including methanol, oil, water, lubricants, fuel systems (E85/E10 compatible), coolants and vacuum service.

Operating Temperature Range: -40°F to 302°F

Operating ...

Tube: nitrile blend, smooth and black

Cover: Nitrile/SBR, fabric impression, yellow, pin-pricked.

Reinforcement: 2-ply synthetic fabric.

TEMPERATURE RANGE:-25°F (-32°C) to +200°F (+93°C)

Application: For rugged air duct service in mining, quarries, construction, sandblasting, industrial air placement, and equipment rental

Feature: ...

Fuel oil hoses are designed to transport fuel oil and other petroleum products, such as gasoline, diesel, and kerosene.

For conveyance of liquid gas, home burner system, grill, oil-resistant

Jackhammer Hose is used in rock drilling mines, tunnels, quarries, construction, road building, and others

What Is A Textile Braided Hose?

A textile braided hose is a type of hydraulic hose that is made from multiple layers of fabric or yarn. The inner layer of the hose is usually made from a synthetic rubber material, while the reinforcement layer is made from a textile material.

The layers are then bonded together using a special adhesive or vulcanization process. The result is a hose that is strong, flexible, and durable.

Compared to steel wire reinforced hoses, textile braided reinforced hydraulic hoses are designed for hydraulic hose applications in medium and low pressure conditions.

Differences between wire braided and textile braided hoses?

A textile braided hydraulic hose consists of a synthetic rubber tube, a textile braided reinforcement layer, and a synthetic rubber outer layer. A wire braided hydraulic hose consists of a synthetic rubber tube, a wire braided reinforcement layer, and a synthetic rubber outer layer. Textile Braided hoses are more more flexible than Wire Braided hoses. but the strength of Wire Braided hoses is higher than Textile Braided hoses. and Textile Braided hoses Abrasion resistance is better than Wire Braided hoses. and Textile Braided hoses cost is lower. Choosing the right hydraulic hose reinforcement is important. Wire braided is ideal for high-pressure applications and environments with high abrasion. Textile braided is suitable for applications requiring flexibility and good abrasion resistance, but may not be suitable for extremely high pressures. By considering the specific requirements of your application, you can choose the right type of reinforcement for your hydraulic hose.

How Are Textile Braided Hoses Made?

The manufacturing process for braided textile hoses involves several steps.

Fiber Selection: The first step in manufacturing a textile braided hose is to select the appropriate fibers. Synthetic or natural fibers such as polyester, nylon, or aramid are often used due to their strength and durability.

Braiding: The selected fibers are then braided together using a specialized braiding machine. The machine may use different patterns or weaves to create the desired level of strength and flexibility in the hose.

Inner Tube Installation: Once the braiding is complete, an inner tube made of rubber, plastic, or other material is inserted into the braided fibers. This inner tube provides a smooth, non-porous surface for fluid to flow through and helps to reinforce the hose.

Cover Application: A cover is then applied to the hose to protect it from abrasion, weather, and other environmental factors. This cover can be made of materials such as neoprene, PVC, or polyurethane.

Curing: After the cover is applied, the hose is cured to ensure that the materials are properly bonded together. This may involve subjecting the hose to high temperatures or pressures in a specialized curing chamber.

Testing: After the hose is cured, it is tested to ensure that it meets the manufacturer's quality and performance specifications. This may involve subjecting the hose to high pressures or temperatures to check for leaks or other problems.

The manufacturing process of textile braided hose requires expertise and equipment, as well as strict adherence to manufacturing standards.

Benefits of Textile Braided Hoses

There are several benefits to using textile braided hoses. One of the main benefits is their strength and durability. The fabric or yarn layers in the hose provide additional strength and flexibility, making them ideal for use in applications where the hose will experience a lot of wear and tear. Another benefit of these hoses is their ability to withstand high temperatures and pressures. This makes them a popular choice for hydraulic systems and other common high-temperature and high-pressure applications.

Flexibility: Textile braided hoses are highly flexible, making them ideal for applications where the hose needs to bend or twist.

Strength: The multiple layers of fiber used in textile braided hoses provide high tensile strength, making them resistant to kinking and crushing.

Durability: Textile braided hoses are very durable and can withstand a wide range of temperatures, pressures, and environmental factors.

Abrasion resistance: The covering on textile braided hoses helps protect the hose from abrasion, extending the life of the hose.

Lightweight: Textile braided hoses are generally lighter in weight than other types of hoses, making them easier to handle and operate.

Versatility: Textile braided hoses are suitable for a variety of applications, including those involving air, water, oil, and other fluids.

Cost-effective: Textile braided hoses are generally less expensive than other types of hoses, making them a cost-effective choice for many applications.

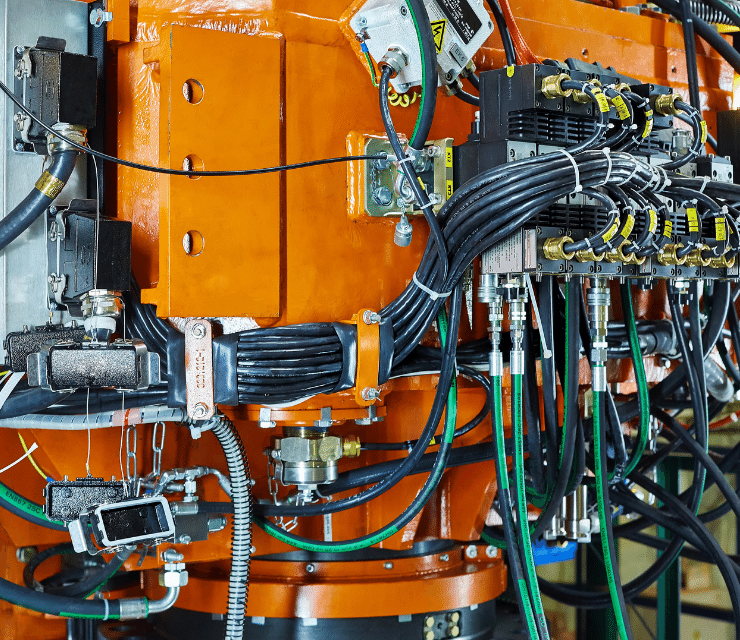

Common Applications of Textile Braided Hoses

Textile braided hoses are used in a wide range of applications, from irrigation systems to hydraulic machinery. Some common applications include:

Hydraulic systems

Irrigation systems

Automotive fuel lines

Air conditioning systems

Chemical transfer

What are textile braided air hoses assemblies made of? How are they different from other types of air hoses?

Textile braided air assemblies consist of a reinforced rubber hose with an outer layer of braided textile material. This construction provides high flexibility and excellent kink resistance, making it ideal for applications that require frequent movement or bending of the hose. Textile braided air assemblies also have higher burst pressure ratings than standard rubber hoses, making them suitable for use in industrial environments that require high-pressure air transfer

Can textile braided air hoses be used with different types of fittings?

Yes, they can be easily paired with other types of fittings depending on the needs of your application. The flexibility of textile braiding allows it to be easily installed on a variety of fittings without compromising air flow or structural integrity.

Are there any temperature limitations when using textile braided air components?

Textile braided air components have a temperature range of -40°C (-40°F) to 93°C (200°F), making them suitable for most industrial applications that require compressed air delivery temperatures below 200°F. However, if your application requires a higher temperature range, we recommend that you contact our technical team to see if we can provide a custom solution based on your specific requirements.

Choosing the Right Textile Braided Hose

When choosing a textile braided hose, there are several factors to consider. One of the most important factors is the size of the hose.

The size of a hydraulic hose will determine its flow rate and the amount of pressure it can handle. Other factors to consider include the material type of the hose, the temperature and pressure ratings, and the length of the hose.

Maintenance and Care of Textile Braided Hoses

Proper maintenance and care of a textile braided hose can help extend its life and prevent damage.

Regularly inspect the hose for any signs of wear, such as cracks or fraying

Clean the hose regularly to remove any dirt or debris that could cause damage or clogging of the hose. We recommend regular washing with warm water and mild soap to remove any dirt or debris that may have accumulated over time. Avoid using harsh chemical cleaners, as these can damage the hose material and compromise its structural integrity.

When not in use, store the hose properly, coil it neatly, and away from any heat sources or sunlight.

Buying Guide to Reinforcement Selection for Hydraulic Hose

Textile Braid: This type of hose is reinforced with one or more layers of braid, which gives the hose good flexibility in low-pressure applications such as return lines and air/lube lines.

Wire Braid: Single, double, or even quadruple layers of high-strength steel wire braid provide strength and pressure resistance to this type of reinforced hose. These hoses are suitable for medium-pressure applications such as agricultural equipment and material handling.

Spiral Wire Reinforced: This reinforced hose has a spiral of steel wire embedded within the hose wall, which helps balance flexibility and pressure resistance. It is ideal for demanding applications such as construction equipment and heavy machinery.

What type of hydraulic hose reinforcement do I need?

For strength, especially when the potential for shock loads is high, the best choice is a spirally wound reinforced hydraulic hose. If flexibility is key, then a braided hose will suffice. However, neither braiding nor spiral reinforcement alone will prevent the hose from collapsing in on itself in the presence of vacuum pressure. For suction hoses, spiral reinforcement is required.

how to choose the right hydraulic hose

When selecting a rubber hose, it is important to consider factors such as the hose's size, temperature and pressure ratings, compatibility with the intended fluid or application, and any specific industry standards that need to be met. Regular inspections, proper maintenance, and storage in the right environment are necessary to ensure the longevity and safe operation of the rubber hose.

Pressure: If your application requires high pressure, a wire braided hose is generally a better choice.

Flexibility: If flexibility is a priority, a textile braided hose is a good choice.

Abrasion resistance: Both types have good abrasion resistance, but textile braided hoses may be slightly better in this regard.

Cost: If cost is a major concern, then textile braided hoses are generally less expensive.

By carefully evaluating these factors, you can select the most appropriate hydraulic hose for your specific needs.

Conclusion

Textile braided hoses are a versatile and durable hose that can be used in a wide variety of applications. They offer many advantages, including strength, flexibility, and the ability to handle high temperatures and pressures.

Whether you use textile braided hoses for hydraulic systems, irrigation, or chemical delivery, it is important to choose high-quality hoses that are suitable for your specific application.

Choosing Sinopulse textile braided hoses ensures that your equipment runs smoothly and efficiently, minimizing downtime or maintenance issues. Sinopulse is a factory specializing in the production of hydraulic hoses, industrial hoses, and fire hoses. It enjoys a high reputation in hydraulic hose manufacturing technology, quality control, etc. Feel free to contact us. If you have any needs, you may contact us!