Sinopulse Industrial Hoses for All Your Fluid Transfer Needs

Chemical Transfer Hoses are designed with chemical resistance to negligible or limit chemical reactions and prevent hose damage. We offer hoses that are compatible with acids, bases, solvents and other harsh chemicals.

Composite hose assemblies are used in any application that benefits from a flexible, safe and chemically resistant hose.

Heavy-duty suction and discharge dock hose designed for transferring petroleum product up to 50 %aromatic content from tankers and barges, bunkering service, and industrial applications.

PVC suction hose is a type of flexible hose that is commonly used in industrial and agricultural settings.

FDA-approved food hose designed for the suction and delivery of foods such as milk, Juice, beer, edible oil, dairy products, etc.

Pressure washer hoses are designed to transport your water from one place to the other for professional pressure washers. The high-quality frame is able to withstand extreme temperatures and pressures so you can safely and efficiently clean your workplace.

A water suction and discharge hose is used to transfer water from one place to another. It is often used in agricultural, industrial, and construction applications.

Steam Hose is a hose that can be used to transmit high-temperature and high-pressure steam. It has the characteristics of high-temperature resistance, high-pressure resistance, and corrosion resistance.

Designed for transfer of multiple types of hydraulic Fracking fluids from tank trucks. And also designed for the demands of high working pressures of hydraulic fracturing operations.

Complete your hose assembly with our extensive selection of fittings and accessories. We offer clamps, couplers, adapters, and more to ensure your connection is secure and leak-proof.

Sinopulse Industrial Hoses Applications

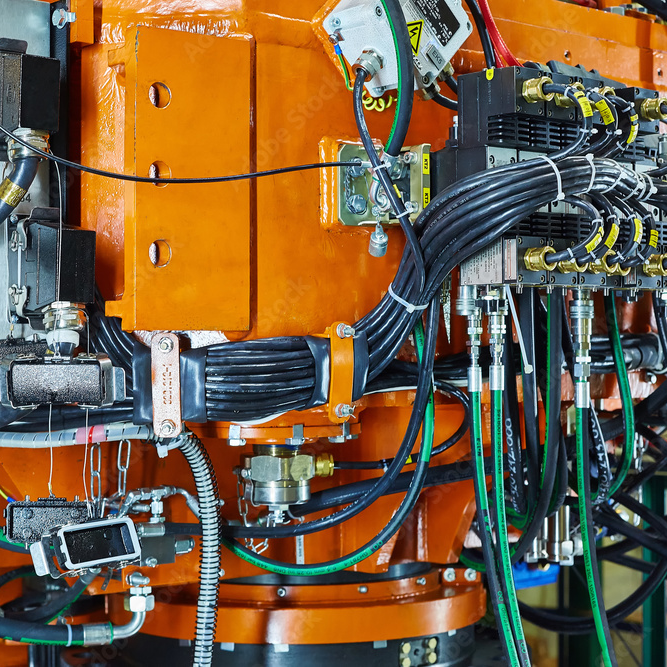

Designed for high-pressure applications, our hydraulic hoses are perfect for construction, agriculture, and manufacturing.

Our chemical-resistant hoses are ideal for transferring various chemicals, solvents, and corrosive liquids in multiple industries.

Suitable for general-purpose air and water applications, these hoses are perfect for use in mining, construction, and industrial settings.

Designed to meet strict hygiene standards, our food and beverage hoses are perfect for transferring food, beverages, and dairy products.

Ideal for abrasive materials, our material handling hoses are designed for use in industries such as mining, construction, and manufacturing.

Designed to withstand high temperatures, our steam hoses are perfect for various industries, including chemical and food processing.

At Sinopulse, we understand that every business has unique requirements. We offer custom industrial hose solutions tailored to your specific needs. Our team of experts will work closely with you to design and manufacture industrial hoses that meet your exact specifications.

- Gallery

- Manufacturing

- Laboratory

- Packaging & Shipping

- Certification

Our factory has passed ISO 9001 and MSHA certificates.