EN 857 2SCHydraulic Hose

High-pressure and 2 wire braid EN 857 2SC hydraulic hose is suitable for hydraulic systems where tight bends and maximum abrasion resistance are urgently required. Its pulse performance and flexibility, superior to SAE 100R2 and SAE 100R16, make it popular in many applications. Chemical and weather resistance extends the life of the entire hose. High-tensile steel braid withstands high working pressures and tight bend radii. Oil-resistant hose will not deform when transporting water- and petroleum-based hydraulic fluids in the -40°C to 100°C range.

EN 857 2SC hose comprises an inner tube, two steel wire braid reinforcement layers, and a synthetic rubber cover.

The inner tube of the EN 857 2SC hose is made of synthetic rubber that is resistant to hydraulic fluids, while the steel wire braid reinforcement provides high tensile strength and resistance to pressure. The synthetic rubber cover offers protection against abrasion, weathering, and ozone.

EN 857 2SC hose is used in high-pressure hydraulic systems with petroleum and water-based fluids. This hose is designed to withstand pressure and temperature extremes, making it suitable for construction, agricultural, and industrial applications. Some examples of applications where EN 857 2SC hose is commonly used include:

- Construction: EN 857 2SC hose is used in construction equipment such as excavators, bulldozers, and cranes.

- Agriculture: EN 857 2SC hoses are also used in cylinders and motors in the hydraulic systems of agricultural machinery such as tractors, combines, and harvesters.

- Industrial: EN 857 2SC hose is used in various industrial applications, such as manufacturing, mining, and oil and gas.

EN 857 2SC Structure:

Inner Tube: high quality synthetic rubber, making the hose resistant to abrasion, corrosion and oil.

Reinforcement: two layers of high tensile braided steel wires, making the hose work well in high pressure environment.

Cover: abrasion, corrosion, weather, ozone, aging, sunlight and cut resistant synthetic rubber, making the hose have long service life.

EN 857 2SC Feature

Working temperature: -40 °C to +100 °C.(-40°F to 212°F)

ID: 1/4-inch to 1-1/4-inch

Working Pressure: Up to 5800 PSI at 1/4” ID

Burst Pressure: Up to 23200 PSI

Safety Factor: 4:1

Meets performance requirements: EN 857 2SC hose Meets or exceeds the performance requirements of SAE 100R16, EN 857 2SC, flame retardant USMSHA certified, higher EN/DIN pressures, SAE J1942/USCG.

High pressure Application range: EN 857 2SC Hydraulic hose is the ideal hose for high pressure applications requiring tight bends. EN 857 2SC hose is capable of handling petroleum and water-based hydraulic fluids.

Excellent pulsation performance: EN 857 2SC hose has Excellent pulsation performance!

Flexible hoses: EN 857 2SC is more flexible than EN853 2sn hoses.

The specification of EN 857 2SC steel wire reinforced hydraulic hose

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| EN857 2SC-04 | 1/4" | 6.4 | 14.2 | 40.0 | 5800 | 160 | 23200 | 75 | 0.296 |

| EN857 2SC-05 | 5/16" | 7.9 | 16.0 | 35.0 | 5075 | 140 | 20300 | 85 | 0.327 |

| EN857 2SC-06 | 3/8" | 9.5 | 18.3 | 33.0 | 4785 | 132 | 19140 | 90 | 0.398 |

| EN857 2SC-08 | 1/2" | 12.7 | 21.5 | 27.5 | 3988 | 110 | 15950 | 130 | 0.500 |

| EN85 72SC-10 | 5/8" | 15.9 | 24.7 | 25.0 | 3625 | 100 | 14500 | 170 | 0.632 |

| EN857 2SC-12 | 3/4" | 19.1 | 28.6 | 21.5 | 3118 | 86 | 12470 | 200 | 0.738 |

| EN857 2SC-16 | 1" | 25.4 | 36.6 | 16.2 | 2393 | 66 | 9570 | 250 | 1.034 |

Sinopulse Factory

Raw Material:

Imported rubber material Vietnam and Thailand

High tensile strength 2750Mpa steel wire from China's first-class factory

Powerful, safe and stable hydraulic hose products

Good dispersibility, high bearing pressure and superior pulse performance.

Excellent oil resistance, heat resistance and aging resistance.

Excellent bending resistance and fatigue resistance

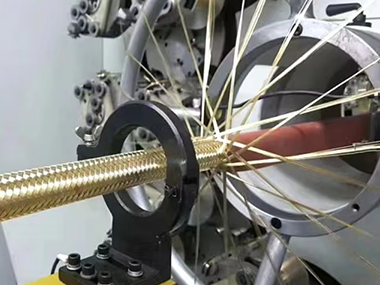

Factory Workshop:

Sinopulse is a 100% manufacturer of hydraulic hoses and industrial hoses, including all oilfields, agriculture, transportation, construction, mining, and forestry.

Daily output 500,000 meters of hoses, workshop covering 40,000 m²

40 production lines, involving high-speed joint machines, braiding machines, high-speed spiral machines, Italy VP automatic industrial machines, and Complete series Laboratory Testing Equipment

120 Skilled workers, 6 Engineers with 2 technical counselors from famous international companies,2 QC departments, and 2 warehouse managers are fall of our lovely people.

50 Sales and three groups of logistics specialists serve our clients from Italy, Germany, Uk, Spain, the USA, Canada, Brazil, Argentina, Panama, Peru, Chile, Viet Nam, Indonesia, Australia, Romania

Laboratory:

Our factory introduces a full range of laboratory testing equipment. It has advanced laboratory capabilities to conduct product quality testing and research and development work to ensure stable and excellent product quality.

After purchasing raw materials, we test each batch to ensure they meet our product's technical requirements.

After production, we test each hose, its working and burst pressure, and conduct a pulse test for each order to ensure that it is 100% qualified after leaving the factory.

We strive to provide our customers with top-notch hoses, doing everything we can to ensure their quality.

"Let our end users feel comfortable in use and safe in driving!" is our common goal.

Product packaging:

1. When packing hydraulic hoses, cartons or wooden boxes according to customer requirements.

2. We will pack the hose after finishing the hose production.

3. Generally, woven bags and plastic films are used for packaging.

4. Special packaging can be provided according to customer requirements. Special packaging is a request of Edible ACC Ording customers.

Continuous Brand Layline Example:

| SINOPULSE HYDRAULIC HOSE G2SC-4 EN 857 2SC 1/4" (DN6.3) Max. W.P. 40MPa (5800PSI) -2Q11- |

Find a trusted hose factory. Any requirements and problems can ask us at any time.

Hot Products

What is EN857 2sc

EN 857 2SC steel wire reinforced hydraulic hose is similar to EN 853 2SN steel wire reinforced hydraulic hose in structure. The difference is that it has smaller outside diameter, which is suitable for the equipment piping whose installation space is compact and narrow. It is also composed of three parts: tube, reinforcement and cover. The tube is made from oil, abrasion and corrosion resistant synthetic rubber, making it transport water and petroleum-based hydraulic fluids without any deformation in the working temperature of -40 °C to +100 °C. The reinforcement is made from two layers of high tensile steel wires, making the hose highly resistant to high pressure. Therefore, the hose has excellent performance in the high pressure working conditions. The cover is made from high quality synthetic rubber, making the hose resistant to abrasion, corrosion, chemical fluids, weather, ozone, aging, sunlight and cut.

What is the different between EN857 2sc and 100r16s

EN is the British standard and SAE is the American standard, they are the same in terms of dimensional pressure, etc.

What is en857 2sc hose?

EN857-2SC double wire braided hydraulic hose is a high-performance hydraulic hose, widely used in industrial and mechanical equipment, especially high-pressure hydraulic systems, softer than 2sn

How many HP does 2sc-3/8" have?

The inner diameter of 2sc-3/8" hose is 1/4", the working pressure is 4800 psi, and the burst pressure is 19000 psi.

What is 2sc hose?

EN857 2sc high pressure hydraulic oil pipe, oil-resistant hydraulic hose, made of special rubber with good oil resistance and weather resistance, reinforced with copper-plated steel wire, and the appearance is black glossy or black cloth.

What do the numbers on the hydraulic hose mean?

The numbers on the hydraulic hose indicate the size of the hose. They usually refer to the inner diameter, outer diameter and rated pressure of the hose

What is the pressure rating of en857 2sc hose?

The rated pressure of en857 2sc hose varies according to the diameter of the hose. For example, a 3/8" diameter 2SC 2 Wire Hydraulic The 1/2" diameter 2-wire hydraulic hose has a working pressure of 4800 PSI, the 3/4" diameter 2-wire hydraulic hose has a working pressure of 3100 PSI, and the 1" diameter 2-wire hydraulic hose has a working pressure of 2400 PSI.

What is the pressure rating of en857 2sc?

The pressure rating of en857 2sc hydraulic hose varies depending on its diameter, but generally ranges from about 23000 psi (smaller diameter) to 9500 psi (larger diameter). It is important to consult the manufacturer's specifications for the exact pressure rating that corresponds to a specific hose size.

What is en 857 2sc?

en857 2SC hose is composed of double single wire braid reinforcement and is designed to handle medium pressure applications, commonly used in industrial and mechanical equipment

How to read hydraulic hose numbers?

Hydraulic hose numbers usually indicate the specifications of the hose, including its diameter, pressure rating and type. For example, a hose marked "1/4- WP 3000 PSI" means that it has a 1/4-inch inner diameter, size 04, and a working pressure of 3000 PSI.

Where can en857 2SC hose be used

EN857-2SC hose is suitable for a variety of hydraulic systems, especially when it comes to delivering hydraulic oil in confined spaces

How is en857 2SC hose composed

EN857-2SC hose is a high-pressure wire braided hydraulic hose that is often used for hydraulic oil delivery in confined spaces. Its structure includes an oil-resistant synthetic rubber inner layer, two wire braided reinforcement layers, and an oil-resistant and weather-resistant synthetic rubber outer layer. This design makes the EN857-2SC hose ultra-flexible and high-pressure, suitable for various occasions requiring high-pressure hydraulic transmission.

How to crimp the joint on the EN857 2SC hose

This hydraulic hose does not need to peel off the outer rubber layer when crimping the joint, and can be crimped directly using a crimping machine

What is EN 857 2sc

EN 857 2SC steel wire reinforced hydraulic hose is similar in construction to EN 853 2SN steel wire reinforced hydraulic hose. The difference is that it has a smaller outside diameter and is suitable for equipment piping with compact and narrow installation spaces. It also consists of three parts: tube body, reinforcement and cover. The hose is made of oil-, abrasion- and corrosion-resistant synthetic rubber, allowing it to transport water and petroleum-based hydraulic fluids at operating temperatures ranging from -40°C to +100°C without any deformation. The reinforcement layer is made of two layers of high-strength steel wire, which makes the hose highly resistant to high pressure. Therefore, the hose has excellent performance under high pressure working conditions. The outer rubber layer is made of high quality synthetic rubber, which makes the hose resistant to abrasion, corrosion, chemical liquids, weather, ozone, aging, sunlight and cutting.

What is DIN EN 857 2sc

EN857 2SC is a European standard for steel wire braided hydraulic hoses. The standard specifies the construction, materials, performance requirements and test methods of hydraulic hoses, etc. EN857 2SC hydraulic hoses are commonly used in low and medium pressure hydraulic piping systems, especially for industrial environments that require high temperature, corrosion and abrasion resistance. Due to its excellent performance, this hose is widely used in ships, vehicles, industry and other fields.

Why choose China EN857 2sc factory - Sinopulse

Sinopulse has established a strict quality assurance system and passed ISO9001 certification. The main products have reached the international level of the same industry after testing by the relevant departments. Our main products: steel wire reinforced hydraulic hose, steel wire spiral hydraulic hose, high pressure steam hose, high pressure air hose, textile reinforced hydraulic hose, thermoplastic hydraulic hose, nylon resin hose and rotary drilling hose. Our products are characterized by high pressure resistance, high temperature resistance, high flexibility, small pulse-pressure deformation, large use length and easy maintenance. Therefore, they are widely used in engineering machinery, coal, petroleum, chemical, metallurgy, mining, construction and transportation industries.

What is 2sc hydraulic hose

2SC hydraulic hose is structurally similar to wire-reinforced EN 853 2SN hydraulic hose. The difference is that its outside diameter is smaller, making it suitable for equipment piping with a compact, narrow installation space.

May i buy bulk 2sc hydraulic hose?

Of course you can do that, because the hoses we produce are bulk Hydraulic hose can be cut to desired lengths and compatible hose fittings can be attached to the end of the hose to create custom hydraulic hose assemblies that can be attached to equipment. Hydraulic hoses are used to transfer fluids in high-pressure petroleum and water-based hydraulic systems commonly found in industrial, mining and manufacturing equipment. These hoses are reinforced to maximize their strength.