Wąż hydrauliczny EN 856 4SP

Węże hydrauliczne EN 856 4SP | Wysokociśnieniowe

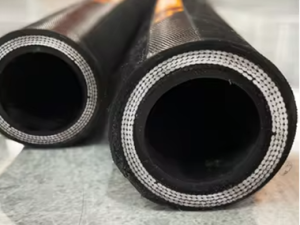

Wąż EN 856 4SP jest wysokociśnieniowym wężem hydraulicznym z zbrojenie spiralne czterodrutowe Zaprojektowane tak, aby sprostać ekstremalnym warunkom i zapewnić niezawodną pracę w zastosowaniach ciężkiego sprzętu.

Wąż EN 856 4SP jest wąż hydrauliczny wielospiralnyNadaje się do zastosowań zewnętrznych, takich jak sprzęt leśny i górniczy. Wąż jest odporny na płomienie, ładunki elektrostatyczne, ścieranie oraz zmęczenie impulsowe. Podobny do węża hydraulicznego EN 856 4SHWąż EN 856 4SP ma wyższe ciśnienie robocze w tej samej temperaturze roboczej. Składa się z trzech części: rury, wzmocnienia i osłony. Rura wykonana jest z kauczuk syntetyczny odporny na olej, dzięki czemu wąż jest odporny na ścieranie i korozję oraz może bez problemu przesyłać płyny hydrauliczne na bazie ropy naftowej w temperaturach od -40°F do +212°F. Wzmocnienie wykonane jest z cztery warstwy spiralnego wzmocnienia z drutu stalowego o wysokiej wytrzymałości na rozciąganie, zapewniając mu wytrzymałość i trwałość niezbędną do wytrzymania wysokich ciśnień do 6000 psi. Pokrywa wykonana jest z kauczuk syntetyczny odporny na ścieranie i ozon, dzięki czemu wąż jest odporny na ścieranie, korozję i starzenie, zaakceptowane przez MSHA

Wąż hydrauliczny DIN EN 856 4SP jest przeznaczony do zastosowań wysokociśnieniowych z użyciem płynów hydraulicznych na bazie ropy naftowej. Ten wysokiej jakości wąż hydrauliczny spełnia rygorystyczne wymagania normy DIN EN 856 4SP, zapewniając niezawodną pracę i długą żywotność w wymagających zastosowaniach. Czterowarstwowa spiralna konstrukcja z drutu stalowego o wysokiej wytrzymałości oraz wysokie ciśnienie robocze sprawiają, że idealnie nadaje się do stosowania w wysokociśnieniowych przewodach hydraulicznych o ciśnieniu od 165 do 450 barów.

Struktura

Dętka: Wysokiej jakości czarny kauczuk syntetyczny odporny na olej

Wzmocnienie: Cztery spiralne warstwy drutu stalowego o wysokiej wytrzymałości na rozciąganie

Masa pokrywająca: Czarna, odporna na ścieranie, korozję i olej guma syntetyczna, odporna na działanie różnych środowisk, opadów i promieniowania UV.

Funkcja

Zakres temperatur: -40°C do +125°C (-40°F do +230°F)

Aplikacja: Do płynów hydraulicznych na bazie ropy naftowej stosuje się zastosowania wymagające bardzo wysokiego ciśnienia.

Specyfikacja węża hydraulicznego EN 856 4SP

| Numer części | ID | OD | WP | BP | BR | Waga | |||

| Kropla | Cal | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| EN8564SP-04 | 1/4" | 6.4 | 18.0 | 45.0 | 6525 | 180 | 26100 | 150 | 0.620 |

| EN8564SP-06 | 3/8" | 9.5 | 20.8 | 44.5 | 6453 | 178 | 25810 | 180 | 0.730 |

| EN8564SP-08 | 1/2" | 12.7 | 24.0 | 41.5 | 6018 | 166 | 24070 | 230 | 0.900 |

| EN8564SP-10 | 5/8" | 15.9 | 27.6 | 35.0 | 5075 | 140 | 20300 | 250 | 1.130 |

| EN8564SP-12 | 3/4" | 19.1 | 31.8 | 35.0 | 5075 | 140 | 20300 | 300 | 1.480 |

| EN8564SP-16 | 1" | 25.4 | 39.7 | 28.0 | 4060 | 112 | 16240 | 340 | 1.980 |

| EN8564SP-20 | 1.1/4" | 31.8 | 50.8 | 21.0 | 3045 | 84 | 12180 | 460 | 2.910 |

| EN8564SP-24 | 1.1/2" | 38.1 | 57.2 | 18.5 | 2683 | 74 | 10730 | 560 | 3.430 |

| EN8564SP-32 | 2" | 50.8 | 69.8 | 16.5 | 2393 | 66 | 9570 | 660 | 4.890 |

Pobierać

katalog węży hydraulicznych sinopulse

Fabryka Sinopulse

Surowiec:

Importowany materiał gumowy Wietnam i Tajlandia

Wysoka wytrzymałość drutu stalowego 2750Mpa z fabryki najwyższej klasy w Chinach

Mocne, bezpieczne i stabilne produkty z wężami hydraulicznymi

Dobra dyspersyjność, wysokie ciśnienie nośne i doskonała wydajność pulsacyjna.

Doskonała odporność na olej, ciepło i starzenie.

Doskonała odporność na zginanie i zmęczenie

Warsztat fabryczny:

Sinopuls jest producentem 100% węży hydraulicznych i przemysłowych, obejmujących wszystkie dziedziny przemysłu naftowego, rolnictwa, transportu, budownictwa, górnictwa i leśnictwa.

Dzienna wydajność 500 000 metrów węży, powierzchnia warsztatu 40 000 m²

40 linii produkcyjnych, w tym maszyny do szybkiego łączenia, maszyny do oplatania, maszyny spiralne o dużej prędkości, automatyczne maszyny przemysłowe włoskiej firmy VP oraz kompletna seria urządzeń do badań laboratoryjnych

W skład naszego wspaniałego zespołu wchodzi 120 wykwalifikowanych pracowników, 6 inżynierów, 2 doradców technicznych ze znanych międzynarodowych firm, 2 działy kontroli jakości i 2 kierowników magazynu.

50 specjalistów ds. sprzedaży i trzy grupy specjalistów ds. logistyki obsługują naszych klientów z Włoch, Niemiec, Wielkiej Brytanii, Hiszpanii, USA, Kanady, Brazylii, Argentyny, Panamy, Peru, Chile, Wietnamu, Indonezji, Australii i Rumunii

Laboratorium:

Nasza fabryka dysponuje pełną gamą sprzętu do badań laboratoryjnych. Dysponujemy zaawansowanymi możliwościami laboratoryjnymi, umożliwiającymi przeprowadzanie testów jakości produktów oraz prac badawczo-rozwojowych, aby zapewnić stabilną i doskonałą jakość produktów.

Po zakupie surowców testujemy każdą partię, aby mieć pewność, że spełnia ona techniczne wymagania naszego produktu.

Po wyprodukowaniu testujemy każdy wąż, jego działanie i ciśnienie rozrywające, a także przeprowadzamy test pulsacyjny dla każdego zamówienia, aby upewnić się, że po opuszczeniu fabryki wąż spełnia wymagania normy 100%.

Dokładamy wszelkich starań, aby dostarczać naszym klientom węże najwyższej jakości, robiąc wszystko, co w naszej mocy, aby zagwarantować ich jakość.

„Aby nasi użytkownicy czuli się komfortowo podczas użytkowania i bezpiecznie podczas jazdy!” to nasz wspólny cel.

Opakowanie produktu:

1. W przypadku pakowania węży hydraulicznych do kartonów lub skrzyń drewnianych zgodnie z wymaganiami klienta.

2. Po zakończeniu produkcji węża zapakujemy go.

3. Do pakowania używa się zazwyczaj worków tkanych i folii plastikowych.

4. Specjalne opakowania mogą być dostarczone zgodnie z wymaganiami klienta. Specjalne opakowania są życzeniem klientów Edible ACC Ording.

Przykład ciągłej linii marki

| SINOPULSE G4SP-06 EN 856 4SP 3/8" (DN10) WP 45MPA (6550 PSI) -XXXXX- |

Znajdź zaufanego fabryka węży. Wszelkie pytania i problemy możesz zgłaszać nam w każdej chwili.

Gorące produkty

Co to jest DIN EN 856 4sp

Wąż hydrauliczny spiralny z drutu stalowego EN 856 4SP nadaje się do hydraulicznego podparcia górnictwa i związanego z nim sprzętu. Wąż jest odporny na płomienie i ładunki elektrostatyczne. Jego struktura jest prawie podobna do węża hydraulicznego spiralnego z drutu stalowego EN 856 4SH, ale może wytrzymać wyższe ciśnienie robocze niż wąż hydrauliczny spiralny z drutu stalowego EN 856 4SH w tej samej temperaturze. Składa się z trzech części: rury, wzmocnienia i osłony. Rura wykonana jest z czarnej, odpornej na olej gumy syntetycznej, dzięki czemu wąż jest odporny na ścieranie i korozję. Wzmocnienie składa się z czterech warstw spiralnego drutu stalowego o wysokiej wytrzymałości i wytrzymałości, który jest specjalnie zaprojektowany do węży gumowych, dzięki czemu wąż jest doskonale odporny na wysokie ciśnienie. Osłona wykonana jest z wysokiej jakości czarnej gumy syntetycznej, dzięki czemu wąż jest odporny na ścieranie, korozję, przecięcia, warunki atmosferyczne, ozon, olej i starzenie. Co ważniejsze, powierzchnia węża przypomina gumę. Dlatego wąż ma dłuższą żywotność.

Jak wybrać odpowiedni wąż hydrauliczny 4SP?

Aby kupić wąż wysokociśnieniowy 4 SP do hydrauliki, należy zapoznać się z warunkami pracy i wymaganiami sprzętu. Oferujemy szeroką gamę takich produktów, różniących się parametrami:

Średnica nominalna kanału. Wskaźniki różnią się w zależności od modelu i wahają się od 4 do 50 mm. Zgodnie z tym oznaczenie na produkcie wskazuje: Wąż EN856 4SP D 12, 20, 50 itd.

Ciśnienie robocze. Ten typ węża przeznaczony jest do średnich ciśnień w zakresie od 165 do 450 atmosfer, w zależności od przeznaczenia produktu.

Ciśnienie rozrywające. W przypadku przewodów czterozwojowych maksymalny dopuszczalny wskaźnik ciśnienia w sieci hydraulicznej wynosi od 660 do 1800 atmosfer.

Promień gięcia. Wskaźnik ten wzrasta wraz ze wzrostem średnicy węża i waha się od 150 do 660 mm.

Temperatura pracy. Dopuszczalny zakres temperatur wynosi od –40 do +100 stopni.

Średnica zewnętrzna i wewnętrzna. Wskaźniki niezbędne do doboru odpowiedniego węża do danego typu sprzętu. Rozmiar ma również znaczenie przy wyborze akcesoriów do węży wysokociśnieniowych: zgodnie z katalogiem lub indywidualnym zamówieniem.

Gdzie stosować wąż hydrauliczny 4SP?

Węże EN 856 4SP stosowane są w przewodach hydraulicznych o bardzo wysokim ciśnieniu, specjalistycznych urządzeniach narażonych na duże zużycie, a także w dynamicznych obiegach olejowych, w przetwórstwie produktów ropopochodnych oraz w zastosowaniach, w których występują uderzenia wodne.

W układach hydraulicznych odpornych na ekstremalnie wysokie ciśnienie i trudne warunki, w zastosowaniach z paliwem, płynem niezamarzającym, powietrzem i wodą, w zastosowaniach z ekstremalnie niskimi temperaturami

Węże hydrauliczne wysokociśnieniowe mają szeroki zakres zastosowań. Główne z nich to:

Sprzęt budowlany, drogowy;

Maszyny rolnicze;

Maszyny i urządzenia komunalne;

Sprzęt do pozyskiwania drewna;

Sprzęt do produkcji ropy naftowej i górnictwa;

Urządzenia przemysłowe do produkcji, innych celów, podwyższonego ciśnienia w sieci hydraulicznej.

Jaka jest różnica pomiędzy rękawami 4SP i 4SH?

Węże 4SP i 4SH mają taką samą liczbę warstw drutu (4). Jednak pomimo podobieństwa zewnętrznego i porównywalności parametrów technicznych, wersja SP charakteryzuje się cieńszą warstwą zewnętrzną i mniejszym promieniem gięcia.

Jaka jest konstrukcja węża 4SP?

Wewnętrzna gumowa osłona węża 4SP zapewnia szczelność węża, odporność na oleje i inne substancje chemiczne znajdujące się wewnątrz węża. Wielowarstwowa metalowa rama (czterowarstwowa w 4SP RVD) chroni przed wpływem ciśnienia wewnętrznego i zewnętrznego oraz ciężaru przesyłanego płynu. Warstwa zewnętrzna wykonana jest ze specjalnej mieszanki gumowej i chroni przed wpływem czynników zewnętrznych (trudne warunki środowiskowe, temperatura, promieniowanie UV, naprężenia mechaniczne).

Aby uzyskać maksymalną wytrzymałość, metalową ramę układa się metodą nawijania w kilku warstwach naprzemiennie z warstwami gumy.

Węże z indeksem 4SP przeznaczone są do średnich ciśnień i wytrzymują ciśnienia od 165 do 450 bar oraz temperatury pracy od -40°C do +100°C.

Czy 4sp można stosować w środowiskach o niskiej temperaturze?

Tak, w wężach przeznaczonych do pracy w ekstremalnie niskich temperaturach (do -50°C) powierzchnia wewnętrzna wykonana jest ze specjalnie dobranych kauczuków syntetycznych lub elastycznych polimerów (kauczuku nitrylowego itp.). W tym ostatnim przypadku, oprócz miękkości, stosuje się elastyczne polimery. Mrozoodporność, większa odporność na agresywne chemicznie ciecze.