Montaż hydrauliczny JIC

What are JIC Fittings?

JIC (Joint Industry Council) fittings originated from the AN (Army-Navy) fittings developed for aviation applications during World War II. The JIC standard was subsequently developed to simplify manufacturing processes and reduce costs. These fittings conform to SAE J514 and ISO 8434-2 standards, can withstand high pressure, and are a reliable choice for various industries.

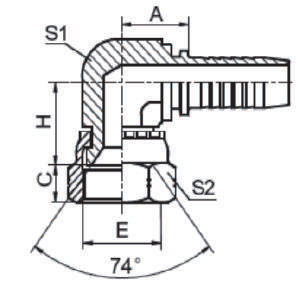

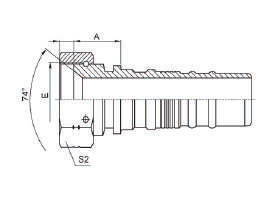

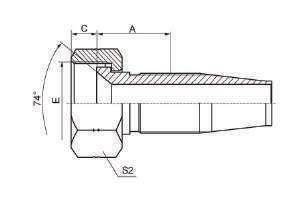

JIC fittings feature a 37-degree flare and utilize a metal-to-metal sealing mechanism, providing a secure mechanical connection. JIC fittings do not require additional sealants to achieve a leak-proof seal. JIC fittings are available in a variety of sizes and conform to 2A/2B thread fit standards.

Zalety

● High-Pressure Resistance: JIC fittings are designed to withstand high pressure, making them ideal for demanding hydraulic applications.

● Reusability: One of their standout features is their reusability, offering long-term value.

● Leak-Proof: The 37-degree flare design minimizes the risk of leaks, ensuring a secure connection.

Wady

● Cost Considerations: While JIC fittings offer many advantages, they may be more expensive than other types of fittings.

● Limited Compatibility: These fittings are not universally compatible with other thread types, which may limit their application in certain systems.

Why Choose JIC Connectors?

Typ gwintu

JIC hydraulic fittings use a 37-degree flare to achieve a metal-to-metal seal.

Mechanizm uszczelniający

The JIC 37-degree flare design provides a secure mechanical seal without the need for additional sealants.

Ocena ciśnienia

JIC fittings are designed to withstand high pressure, making them ideal for demanding hydraulic applications.

JIC Fitting Installation Step-by-Step Guide

Preparation: Before starting, clean the work area to prevent contamination. Ensure all necessary tools and parts are ready.

Środki ostrożności

Thread Inspection: Inspect the threads on the fitting and the hose or pipe. Check for any signs of wear, corrosion, or damage that could affect the connection.

Installation: Align the JIC fitting with the hose or pipe and carefully insert it. Ensure it is properly aligned with the flare or base.

Tightening: Use an adjustable wrench to tighten the fitting until snug. Then tighten another quarter turn to ensure a secure connection.

Maintenance Tips for JIC Hydraulic Fittings

Leak Detection and Prevention

Regular Inspection: Regularly inspect the area around the fittings for signs of leaks. Look for dampness, dripping, or pooling of fluid.

Pressure Testing: Conduct pressure testing to identify any weak points in the hydraulic system.

Sealant: For NPT fittings, it is recommended to reapply thread sealant during maintenance checks to ensure a leak-free connection.

When to Replace Fittings

Kontrola wizualna: Check for signs of wear, corrosion, or damage. If any visible signs are present, the fitting should be replaced.

Performance Issues: If you notice a decline in system performance, such as reduced pressure or fluid leaks, consider replacing the fittings.

Regular Maintenance: Replace fittings regularly according to the manufacturer's guidelines to ensure optimal performance.

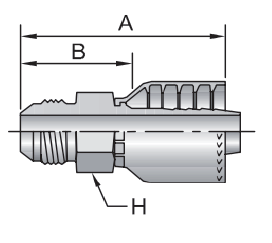

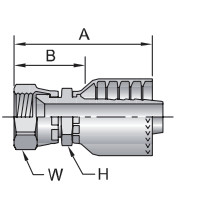

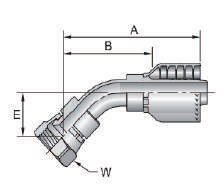

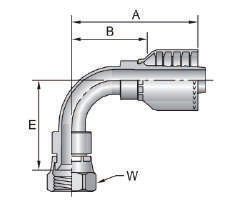

Sinopulse JIC Fittings

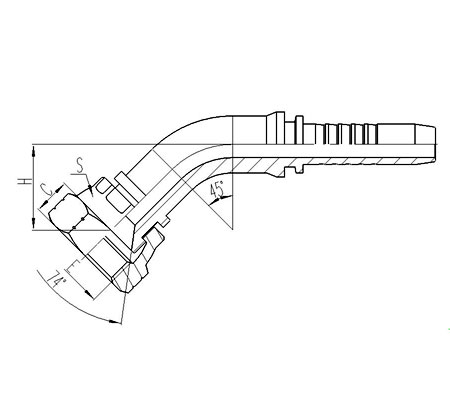

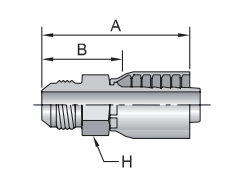

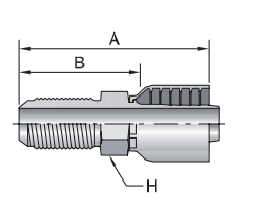

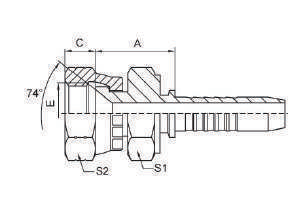

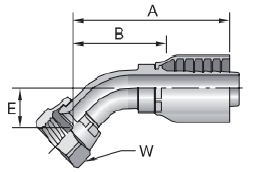

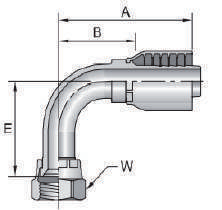

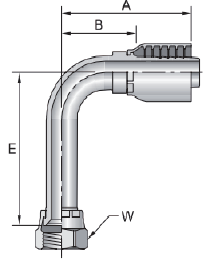

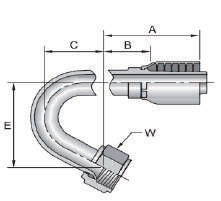

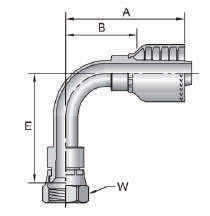

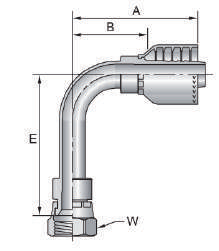

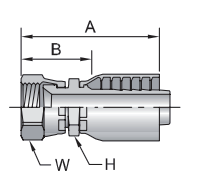

Sinopulse Manufacture JIC and SAE grade hydraulic fittings. Flared, flanged, swivel, face seal, o-ring, and metric couplings are offered. 45 or 90 degree metric elbows and connectors are also provided. Suitable for hose and pipe applications. Serves agriculture, chemical, food, material handling, mining, oil or gas, and petroleum industries.