In the daily operation of industrial equipment, hydraulic hoses play a vital role in transportting hydraulic fluids.

Choosing the wrong material can lead to hydraulic hose leaks and reduced efficiency, or even equipment failures and accidents. Don't worry! Today, Sinopulse will explain the various materials used for hydraulic hoses and how to choose them, helping you reduce operating costs and minimize equipment downtime.

What are hydraulic hoses and their types?

Hydraulic hoses, also known as high-pressure oil hoses or rubber hoses, are the blood vessels of hydraulic systems, transmitting fluids and pressure. Broadly speaking, high-pressure hoses also include hoses used to transport water, steam, and chemical liquids.

Hydraulic hoses are divided into rubber hoses, corrugated metal hoses, and PTFE hoses.

Rubber hydraulic hoses: Oil-resistant hoses typically have inner and outer rubber layers made of chloroprene rubber. Acid, alkali, and high-temperature resistant hoses are made of EPDM, chloroprene rubber, or silicone rubber. The inner and outer rubber layers are typically braided or wound with steel wire, with one to four layers of braid.

Corrugated metal hoses: Metal hoses are stainless steel bellows braided (or wound) with one or more layers of stainless steel wire or mesh. They are corrosion-resistant, high-temperature resistant (-235°C to 500°C), and high-pressure resistant (32 MPa).

PTFE hoses: PTFE hoses consist of a PTFE inner tube and a stainless steel wire reinforcement. Corrosion resistant (resistant to aqua regia and all organic solvents), high temperature resistant (-60℃—250℃), high pressure resistant (35Mp).

Thermoplastic Hydraulic Hose: Thermoplastic hose is a kind of hose made of thermoplastic that can be heated up to 120 degrees and is powered by water pressure or pneumatic. It has the characteristics of lightweight, pressure resistance and corrosion resistance.

Rubber Hydraulic Hose Construction

Hydraulic hoses primarily consist of an inner tube, a middle tube (optionally included), a reinforcement layer (steel wire or other reinforcing material), and a cover tube. The inner tube ensures the conveyed medium can withstand a certain pressure while protecting the steel wire from corrosion. The cover tube protects the reinforcement layer from other types of damage. The reinforcement layer acts as a structural material, providing strength and enabling the hose to withstand higher operating pressures.

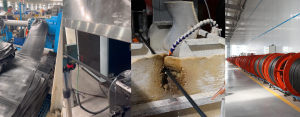

Hydraulic Hose Applications

Hydraulic hoses are widely used in mine hydraulic supports, oilfield extraction, construction engineering, lifting and transportation, metallurgical forging, mining equipment, ships, injection molding machinery, agricultural machinery, various machine tools, and mechanized and automated hydraulic systems across various industrial sectors.

Problems that can arise from choosing the wrong rubber hydraulic hose material:

Leaks

Hose damage: The inner or outer tube breaks due to wear, corrosion, or mechanical damage.

Pulse pressure accumulation damage: Long-term high-frequency pressure pulses cause material fatigue.

Burst

Temperature effects: Hose material strength decreases at high temperatures and becomes brittle at low temperatures.

External mechanical damage: Localized weakening due to scraping, squeezing, or excessive bending during installation.

Surface cracking or outer layer peeling

Ozone/UV aging: Long-term exposure to ozone or sunlight causes hardened rubber to crack.

Chemical corrosion: Exposure to oil, solvents, or chemicals causes degradation of the outer layer.

Low-temperature embrittlement: Loss of rubber elasticity at low temperatures, resulting in cracks when bent.

Hose expansion or deformation

High-pressure expansion: Exceeding the hose's pressure resistance causes the hose to expand.

High-temperature softening: Excessive oil temperature causes the rubber to soften and lose its support.

Internal wear: Fluid particles and impurities wear the inner tube, causing localized bulging.

Inner tube peeling or clogging

Fluid contamination: Impurities in the fluid (metal shavings, water) cause corrosion or peeling of the inner tube.

Fluid compatibility: Fluid incompatibility with the hose material (e.g., some synthetic oils react with rubber).

Extended standing: The inner tube of the hose adheres to the hose due to prolonged inactivity, causing it to peel and form debris.

How to choose the correct rubber hydraulic hose material

The media conveyed by rubber hydraulic hoses determines the choice of inner tube material

When considering the compatibility of hydraulic fluids with hoses, the first thing to consider is the core tube construction. There are many core tube material options, with the five most popular being nitrile rubber (NBR, also known as Buna), neoprene, ethylene propylene diene monomer (EPDM), fluoroelastomer (Viton), and thermoplastics, with NBR being the most commonly used.

NBR is a highly versatile material that performs well in most hydraulic fluid environments. Hydrogenated NBR variants can also function well in highly water-based fluids.

However, regular NBR (Nitrile Butadiene Rubber) will swell, soften, and crack over time due to thermal cycling and oxidation when exposed to water or water glycol. This gradually reduces the hose's mechanical strength and can eventually lead to failure.

For water-based hydraulic fluids, EPDM is a good choice. Have you noticed that pump suction hoses and "truck hoses" are often the same type? Many are made of EPDM rubber and can even be used in vacuum environments.

EPDM (Ethylene Propylene Diene Monomer) is particularly well-suited for applications requiring water-based fluids. Water-based fluids such as glycol mixtures and water-oil emulsions are widely used in places like steel mills. In steel mills, where ambient and local temperatures are high, the advantage of using these water-based fluids is that even if a hose leaks, the hydraulic piping won't become a flamethrower.

Polytetrafluoroethylene (PTFE), more commonly known as Teflon, is also an excellent choice for water-based fluids in high-temperature environments, though it does sacrifice flexibility.

Viton (FKM), a type of fluoroelastomer, provides excellent protection against highly corrosive fluids such as polyol esters and phosphate esters. Phosphate esters are commonly used as fire-retardant fluids in aerospace and have subsequently found their way into steel mills. Both esters are fully synthetic materials designed to resist ignition when exposed to flames and high temperatures. Other hose materials, such as nitrile rubber and EPDM, will degrade and eventually fail under these conditions, so they should never be used to transport fire-resistant fluids.

For example, if the fluid is phosphate ester hydraulic fluid, choose a Parker hose ending in 4. The inner tube is typically made of EPDM, such as series 804, 304, 424, and 774.

Hydraulic Hose Material Selection Quick Guide (Inner Tube)

| Fluid Type / Application | Recommended Material | Key Features | Typical Use Cases |

| General hydraulic oil | Nitrile Rubber (NBR) | Excellent oil resistance, cost-effective | Standard hydraulic systems, mobile machinery |

| High-temperature oil, synthetic fluids | Hydrogenated Nitrile (HNBR) | Improved heat and ozone resistance compared to NBR | Steel mills, high-temp fluid transfer |

| Water-based fluids (glycol, emulsions) | EPDM (Ethylene Propylene Diene Monomer) | Excellent resistance to water, steam, glycol-based fluids | Foundries, water-based hydraulic systems |

| Fire-resistant phosphate ester fluids | Viton (FKM) | High temperature & chemical resistance, ideal for fire-resistant fluids | Aerospace, steel plants using phosphate ester fluids |

| High-corrosive or solvent-based fluids | PTFE (Polytetrafluoroethylene) | Extremely chemical-resistant, wide temp. range (-60掳C to 250掳C) | Chemical processing, aggressive fluids |

Note:

If the transmission medium involves a complex fluid (such as oil-containing coolant or corrosive emulsion), PTFE or fluoroelastomer is recommended.

If the specific composition of the fluid is unknown, it is recommended that the user provide the MSDS (Material Safety Data Sheet) to the supplier for material compatibility assessment.

Pressure-bearing capacity determines the choice of reinforcement lanyer material and structure.

The reinforcement layer is a key component of the hose. It is typically braided with steel wire, high-strength polyester, or nylon yarn, providing excellent pressure resistance and tensile strength. Depending on the requirements, the reinforcement layer can be made of different materials and braiding methods.

Pressure fluctuations are common in hydraulic systems. If a hose has poor pressure resistance, it can be easily damaged by frequent pressure changes. For systems with large pressure fluctuations, it is important to select a hose with good pulse resistance. Specialized reinforcement designs, such as multi-layer steel wire braiding or winding, can better withstand pressure pulses. Specific structures and pressure tolerances are as follows:

1. Low-Pressure Layer (1-2 Layers)

• 1-Layer Steel Wire (Model: 1SN/1ST/1AT):

Single-braided structure for optimal flexibility (bend radius ≤ 8 times the inner diameter)

Pressure range 8-20 MPa, suitable for low-pressure lubrication systems and household hydraulic equipment

• 2-Layer Steel Wire (Model: 2SN/2ST/2AT):

Double-braided reinforcement increases pressure to 20-40 MPa

Ideal for general applications such as excavator hydraulic arms and forklift lift systems

2. Medium- and High-Pressure Layer (3-4 Layers)

• 4-Layer Steel Wire (Model: 4SH/4SP):

Double-wound layer structure (non-braided), with a pressure range of 40-70 MPa

Essential for high-pressure oil lines in injection molding machines and hydraulic systems in mining machinery

3. Ultra-High-Pressure Layer (6 Layers, Customizable)

• 6 Layered Steel Wire (Model: R15/R13):

Three-layer winding stacking, with a pressure resistance exceeding 70-120MPa+

Suitable for extreme high-pressure applications such as oil drilling equipment and aviation hydraulic systems

Hydraulic Hose Material Selection Quick Guide (Reinforcement Layer)

| Operating Conditions / Requirement | Recommended Reinforcement Structure | Key Features | Typical Use Cases |

| Low-pressure systems (< 20 MPa) | 1-Wire Braid (1SN / 1ST) | Good flexibility, lightweight | Lubrication systems, steering systems |

| Medium pressure (20–35 MPa) | 2-Wire Braid (2SN / 2ST) | Cost-effective, good pressure rating | Excavators, forklifts, tractors |

| Frequent pressure pulses | 3 or 4-Wire Spiral / Braid (3SN–4SH) | Superior pulse resistance, long service life | Injection machines, mining trucks |

| High-pressure (40–70 MPa) | 4-Wire Spiral (4SP / 4SH) | Spiral steel structure, very high burst pressure | Tunnel boring, presses, large construction machines |

| Ultra-high pressure (> 70 MPa) | 6-Wire Spiral (6SP / R13 / R15) | Multi-layer spiral, built for extreme loads | Drilling rigs, aerospace systems |

| Lightweight / High Flexibility | Aramid or Nylon fiber braid | Excellent flexibility, fatigue resistance | Robotic arms, compact machinery |

| Non-conductive / Anti-static environments | Non-metal reinforcement + conductive layer | Safe for flammable/explosive environments | Tankers, refueling systems, underground mining |

Note:

Steel Wire Braid: More flexible and suitable for applications with frequent bending; generally used in medium-voltage or general-purpose systems.

Steel Wire Spiral: Stronger and more resistant to high pressure, suitable for systems with heavy loads and severe shock.

Fiber Braid (Polyester/Nylon/Aramid): Suitable for applications requiring lightweight, easy handling, or corrosion resistance, but with lower pressure-bearing capacity than steel wire.

For high-frequency pulse applications, it is recommended to select a reinforcement structure that complies with ISO 18752 or SAE 100R12/R13/R15.

The external environment in which rubber hydraulic hoses are used determines the choice of outer cover material

High temperatures, extreme cold, direct sunlight, and humidity... these different environments pose a severe test for hoses! Choose UV-resistant PVC-coated hoses for outdoor equipment, high-temperature workshops with high-temperature fluororubber hoses, and low-temperature-resistant hydrogenated nitrile rubber (HNBR) hoses for environments below -20°C. A case of cold storage equipment using ordinary hoses resulted in brittle cracking upon exposure to cold, resulting in losses exceeding 100,000 RMB!

The environmental conditions in which hydraulic hoses are exposed to must be considered. In industrial environments, corrosive chemicals or solvents may be present, which can damage or degrade the standard neoprene outer covering. This is where fluororubber (Viton) comes in handy. Surprisingly, it is resistant to all substances except water. Mobile equipment applications involving exposure to chemicals may require more specialized solutions, such as stainless steel braided PTFE.

Hydraulic Hose Material Selection Quick Guide (Outer Cover)

| Environmental Exposure | Recommended Outer Layer Material | Key Features | Typical Use Cases |

| General outdoor use | Neoprene (CR) | Oil-resistant, moderate ozone and weather resistance | Construction, agricultural machinery |

| Prolonged sunlight / UV exposure | EPDM / PVC-coated | Excellent weather & ozone resistance | Outdoor stationary equipment |

| Chemical splash, oils, solvents | Viton® (FKM) / PTFE outer | Superior chemical and temperature resistance | Chemical plants, steel mills |

| High temperature environment | HNBR / Viton® | Heat-resistant (up to 150–200°C), oxidation-resistant | Foundry, injection molding machines |

| Low temperature conditions (< -20°C) | HNBR or cold-weather PVC/NBR blend | Maintains flexibility at sub-zero temperatures | Cold storage, outdoor winter equipment |

| Abrasion and mechanical wear (moving parts) | Wrapped rubber or polyurethane cover | High abrasion resistance, suitable for harsh mechanical friction | Excavators, forklifts, mining applications |

| Explosion-proof / anti-static environments | Conductive rubber + antistatic compound | Prevents static build-up in flammable environments | Fuel delivery, oil & gas, mining |

Note:

The primary function of the cover is to protect the internal structure from environmental factors such as mechanical impact, chemical attack, UV rays, and temperature fluctuations.

To meet multiple environmental requirements simultaneously (e.g., high-temperature and UV resistance), a composite cover or additional protective coating (such as a corrugated jacket, nylon fabric jacket, or silicone fireproof jacket) can be used.

Summary

The performance of hydraulic hoses depends not only on their structural design but also on the correct material selection. Whether operating in high temperatures, high pressures, or corrosive media, only by selecting the appropriate inner layer, reinforcement layer, and outer covering materials based on the operating environment can the safe operation and long-term stability of the hydraulic system be ensured.

As a professional hydraulic hose manufacturer, Sinopulse offers a diverse product line that complies with international standards (such as SAE and EN) to meet the needs of various industries and operating conditions. Choosing the right material not only reduces equipment failures and maintenance costs, but also significantly extends service life and improves production efficiency. If you are unsure about your hose material selection, please feel free to contact Sinopulse and we will provide you with professional solutions.