What is Hose fittings?

Hose fittings are used to connect hoses to equipment. They are one type of pipe fittings. In some cases, they connect hoses of different sizes or repair damaged parts.

There are five common shapes: straight, L-shaped elbows, T-shaped, Y-shaped, and flanges. Hose connection parts include barbs, cap nuts, and ribs. Barbs allow fittings to be screwed into hoses. Cap nuts secure hoses with nuts. Barbs are easy to install, but cap nuts reduce leakage risk.

Materials vary based on application. Common options include stainless steel (corrosion-resistant and durable), resin (high corrosion resistance), and PVC (strong and versatile). The suitable fluid (water, air, chemicals, oil, powder, etc.) depends on the material.

Hose fittings, connectors, adapters, and couplings are different names for the same thing. They are small parts that join hoses together or connect them to other equipment.

Hose fittings come in various shapes, sizes, and materials. Each type has a different purpose. That’s why they are used in residential, commercial, and industrial settings.

When buying hose fittings, you may hear the terms male fitting and female fitting. These refer to the thread position on the fitting.

- Male fittings have a protruding end with external threads. These threads allow them to be inserted into female fittings or other tools with internal threads.

- Female fittings are wider and have internal threads. They enclose and hold male fittings by providing an internal threaded cavity.

There are also quick-connect fittings, which make connections easier. These consist of two main parts: the plug and the coupler (also called a socket).

- The plug is usually a male fitting with external threads.

- The coupler is a female fitting with matching internal threads.

To connect them, simply insert the plug into the coupler and twist. This ensures a fast and secure connection.

What Are the Main Types of Hose Fittings?

Due to their versatility, hose fittings come in various types. However, there are three main types you should know:

1. Water Fittings

Low-Pressure Water Fittings

Starting with the most basic type, you likely have this in your garden—hose connectors. We mainly produce this type to connect water hoses or attach them to other components. These fittings are popular in households, especially for garden hoses and plant irrigation.

Since garden hose fittings touch water directly, it's important to choose rust-resistant materials like stainless steel or brass. Speaking of which, check out our high-quality, rust-resistant, and chemical-resistant stainless steel garden hose QC kit. It includes various hose connectors and plugs for sprinklers, watering wands, and more—all at an affordable price!

High-Pressure Water Fittings

High-pressure water fittings are specially designed for water systems operating at high pressure. These are used in industrial, commercial, and some residential applications. They are built to withstand the greater force and pressure of high-pressure water systems.

High-pressure hose fittings typically use threaded connections, similar to low-pressure fittings. However, they require precise threading and a secure seal to prevent leaks under high pressure. Two common thread standards for these fittings are:

- NPT (National Pipe Thread)

- BSP (British Standard Pipe Thread)

All Sinopulse fittings use NPT threads, meaning they have either tapered male or female threads, depending on the model. These fittings are versatile and can be used for:

- Patio cleaning

- Pressure washing driveways

- Removing tough stains from concrete surfaces

- Prepping surfaces for painting

- Cleaning heavy machinery in industrial settings

These durable fittings ensure leak-free, high-performance water flow for demanding applications.

2. Pneumatic Fittings

First, let’s briefly explain what a pneumatic system is. A pneumatic system includes any equipment or machinery that operates using compressed air or pressurized gas.

If that definition doesn’t catch your eye, think of an air compressor or a dentist’s drill. These are common examples of devices that use this system.

Hose fittings are often used in pneumatic equipment. They connect two hoses or control the direction of airflow.

These fittings are very important, especially in industrial uses. They are made to resist chemicals and have very tight seals to stop leaks.

3. Hydraulic Fittings

In most hydraulic systems, high-pressure hydraulic hoses serve as connection links within the circuit. They help safely transfer fluids between key hydraulic components, such as pumps and motors.

These fluids are not limited to water—they can also include chemicals, petroleum, and minerals. That’s why hydraulic hoses are widely used in engineering and mining sites.

Under such conditions, hydraulic hose fittings are often exposed to harsh and sometimes corrosive substances.

To ensure smooth and safe fluid circulation, we highly recommend using hydraulic fittings that can withstand extreme temperatures and high pressure. They should also be rust-resistant and chemical-resistant.

Hydraulic hoses share some similarities with high-pressure washer hoses since both are designed to transport fluids under high pressure. Their construction allows them to endure the intense pressure generated by their respective systems.

For example, a pressure washer hose transfers pressurized water from the pump to the spray gun or nozzle. It plays a crucial role in maintaining water pressure throughout the cleaning process.

What Are Hydraulic Hose Fittings?

High-quality industrial hydraulic hose fittings are key components in any hydraulic system. These fittings connect hydraulic hoses to various components and machines, facilitating the transfer of hydraulic fluid and power.

Hydraulic fittings come in various sizes, materials, seal types, and levels of temperature and pressure resistance. Some fittings allow or block fluid flow, while others can perform both functions simultaneously.

What Are Industrial Hydraulic Hose Fittings Used For?

Industrial hydraulic hose fittings have multiple applications across various industries, including:

- Construction & Heavy Machinery: Ensure reliable fluid and power transfer in hydraulic systems of excavators, loaders, and cranes, enabling precise control and efficient operation.

- Manufacturing & Industrial Equipment: Used in machine tools, presses, and material handling equipment to ensure smooth operation and minimize downtime.

- Agriculture: Facilitate power and fluid transmission in tractors, harvesters, and irrigation systems, aiding in lifting, steering, and controlling attachments.

- Transportation & Automotive: Found in braking systems, power steering, suspension systems, and hydraulic lifts for cars and heavy trucks.

- Oil & Gas: Essential for drilling, extraction, and transportation, ensuring fluid transfer and control in harsh environments.

Common Types of Industrial Hydraulic Hose Fittings

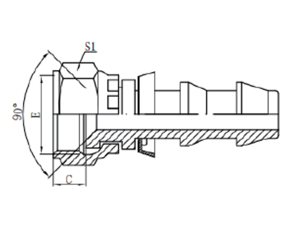

Hydraulic hose fittings mainly fall into three categories: O-ring face seal (ORFS), flare fittings, and tapered thread fittings. While other specialized types exist, these three are the most commonly used.

1. O-Ring Face Seal (ORFS)

ORFS fittings feature an O-ring located on the flat face of the fitting. The seal is achieved by pressing the O-ring against the flat surface of the female fitting.

- Ideal for high-pressure applications, providing a leak-free connection.

- Reliable and secure, handling pressures up to 6,000 PSI.

- Less prone to over-tightening or under-tightening, making them a preferred choice for many hydraulic systems.

2. Flare Fittings

These fittings have threads followed by a beveled edge (or taper) called the flare seat. The threads can be either straight or parallel.

- The threads do not form the seal; instead, the flare seat creates a metal-to-metal seal when tightened.

- Provides a strong and secure connection that withstands vibrations and pressure.

- Commonly used in automotive, aerospace, and industrial machinery.

3. Tapered Thread Fittings

In tapered thread fittings, the male thread is on the outside, and the female thread is on the inside. When tightened, the tapered threads compress together, forming a seal.

- Over time, fluid can seep through the threads, potentially causing leaks.

- Pipe sealant or Teflon tape is often used to prevent leaks, but these materials can break down and contaminate sensitive systems.

- Prone to over-tightening, which can damage the fitting and compromise the seal.

- Due to these drawbacks, tapered thread fittings are often avoided in modern hydraulic and pneumatic systems.

Key Considerations for Other Hydraulic Hose Fitting Features

Hydraulic hose fittings vary in attachment method, shape, and material, each affecting performance, durability, and application.

Crimped vs. Field-Attachable Fittings

-

Field-Attachable (Reusable) Fittings

- Can be installed anywhere without crimping equipment.

- Consist of a socket and a stem, allowing for on-site assembly.

- Useful for emergency repairs but not as strong or reliable as crimped fittings.

-

Crimped (Permanent) Fittings

- Sealed using a crimping machine, ensuring a secure and leak-free connection.

- More widely used than reusable fittings due to greater safety and reliability.

- Require crimping equipment, available in workshop or portable models for on-site use.

Hydraulic Hose Fitting Shapes

Fitting shape determines how hoses connect, change direction, or split/merge fluid flow.

-

Straight Fittings:

- Simplest type, connecting hoses or components in a straight line.

-

Elbow Fittings (45° & 90°):

- Allow the system to change direction while maintaining flow efficiency.

- Available in different angles (e.g., 45° & 90°) for flexible system design.

-

Tee Fittings:

- T-shaped design, used to split or merge hydraulic fluid flow.

- Connects three hoses or components.

-

Cross Fittings:

- X-shaped design, allowing four connections.

- Used for complex hydraulic circuits requiring multiple fluid paths.

-

Flange Fittings:

- Connects hoses to flange-mounted components.

- Provide a secure, leak-proof connection for high-pressure applications.

Material Selection for Hydraulic Fittings

The material of hydraulic fittings impacts durability, pressure resistance, and corrosion resistance.

-

Steel Hydraulic Fittings

- Most common material due to its strength and durability.

- Withstands -65°F to 500°F and is suitable for high-pressure applications.

-

Stainless Steel Hydraulic Fittings

- Enhanced corrosion resistance, ideal for harsh environments.

- Operates in extreme temperatures (-425°F to 1,200°F).

- Can handle pressures up to 10,000 PSI, or even 20,000 PSI with special designs.

- More expensive but highly reliable.

-

Plastic Hydraulic Fittings

- Highly corrosion-resistant, lightweight, and cost-effective.

- Not suitable for high-pressure or high-temperature applications due to fragility.

- Less durable compared to metal fittings.

-

Brass Hydraulic Fittings

- Moderate durability, meeting SAE, ISO, DIN, DOT, and JIS standards.

- Handles -65°F to 400°F with good corrosion resistance.

- Recommended for low-to-medium pressure applications (up to 3,000 PSI).

-

Aluminum Hydraulic Fittings

- Lightweight with excellent corrosion resistance.

- Less durable than steel but widely used in the automotive industry for its high strength-to-weight ratio.

What Are the Most Common Functions of Hose Fittings?

To fully benefit from hose fittings, it’s essential to understand their core functionalities. Below, we outline the top 5 critical functions of hydraulic hose connectors:

1. Safety

When working with high-pressure systems like hydraulic setups, safety is paramount. Always use fittings rated to meet manufacturer specifications to ensure system integrity and prevent catastrophic failures.

2. Extending Length or Connecting Components

Don’t discard hoses simply because they’re too short. Hose fittings allow you to join multiple hoses to extend their length. They also act as adapters to connect hoses to structures like faucets, sprinklers, or hydraulic pumps.

3. Flow Diversion or Merging

Need to redirect or distribute fluid flow? Use specialized fittings like T-fittings or Y-fittings to split flow across multiple hoses. Conversely, these same fittings can merge flows from different sources into a single line.

4. Size Reduction

A lesser-known but vital accessory is the reducer fitting. With two ends of differing diameters, reducers enable seamless connections between narrow hoses and larger openings, ensuring compatibility across components.

5. Flow Control

Whether managing water in low-pressure systems or hydraulic fluid in high-pressure pumps, valve fittings provide precise control over output pressure. By attaching these valves to supply lines, you gain full command over flow rates.

How to Choose the Right Hydraulic Hose Fitting for Your Application

Industrial hydraulic hose fittings are critical components in diverse hydraulic systems. Understanding the types of fittings, their materials, and their typical applications is essential for selecting the ideal connector for your specific needs. The right choice ensures safe and efficient system operation, minimizes downtime, and maximizes productivity.

Key Factors to Consider When Selecting Hydraulic Hose Fittings

- Size

Match the fitting’s inner/outer diameter and thread type to your hose and equipment specifications. Even minor mismatches can lead to leaks or system failures. - Material Compatibility

Fittings are made from materials like carbon steel, stainless steel, or brass. Choose based on:- Fluid type (e.g., oil, water, chemicals)

- Temperature range (extreme heat/cold resistance)

- Corrosion resistance (critical for marine or chemical environments)

- Pressure Requirements

Always select fittings rated for your system’s maximum operating pressure. Exceeding this limit risks catastrophic failure. - Application-Specific Demands

- Static vs. Dynamic Use: Vibration-resistant fittings for moving machinery.

- Environment: Weatherproof or UV-resistant coatings for outdoor systems.

- Ease of Assembly/Disassembly

For systems requiring frequent maintenance, prioritize quick-disconnect fittings or designs with tool-free installation.

Sinopulse Custom Hose Assemblies: Your Trusted Hose & Fitting Solutions

Sinopulse hoses and fittings deliver ultimate fluid transfer solutions for equipment and applications worldwide—from automotive, aerospace, and mining to food & beverage, mobile machinery, and industrial systems. Engineered for:

- Wide working pressure ranges

- Superior abrasion resistance

- Long-term durability

- High-efficiency fluid transfer

Why Choose Sinopulse?

- Professional Manufacturer Since 2011

- 125,000+ Hydraulic & Pneumatic Hoses and Fittings

- Custom Bulk Orders at Competitive Pricing

Shop the Largest Selection of Hydraulic Hose and Hose fittings Solutions

Browse our comprehensive range of standard and high-performance products, including:

- Braided, Spiral, Thermoplastic, and Railway Hydraulic Hoses

- Fittings, Couplings, and Pre-Assembled Components

Pressure-Tested. Temperature-Resistant. Built to Last.

Find the perfect match for your hydraulic system’s demands—shop specifications, compare products, and checkout faster!

Sinopulse Hydraulic Hoses and Fittings

Sinopulse delivers a comprehensive range of standard and high-performance braided, spiral, and thermoplastic hoses with precision-engineered fittings. From individual hoses and fittings to complete assemblies, our reliable hydraulic solutions are engineered to withstand extreme pressures (-40°C to +120°C), abrasive environments, and dynamic industrial applications. Discover the ideal match for your hydraulic system - where ISO 18752 compliance meets customized fluid transfer performance.

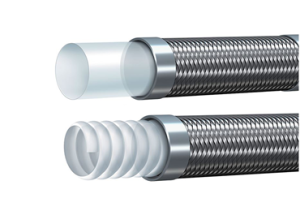

Braided hoses and fittings

Sinopulse offers a high-end line of products to meet tough hydraulic challenges, as well as a standard line of products to fulfill regular functional requirements. Our braided hoses feature advanced wire reinforcement technology and leak-free fittings for superior pressure performance, heat resistance and flexibility, making them ideal for transporting industrial fluids in demanding conditions or specialty products in high or low temperature environments.

Spiral hose and fittings

Sinopulse offers a rugged line of high-pressure, high-impulse, high-performance spiral hose and leak-proof, rust-proof spiral fittings designed to withstand the most extreme pressure applications.

Designed for use with powerful equipment and heavy machinery, our spiral hoses feature four- or six-ply steel wire reinforcement for long-lasting performance under the toughest operating conditions.

Our high-performance spiral hoses and couplings are used in a variety of applications, including construction, mining, oil and gas and more. Choose Sinopulse for reliable, high-performance fluid transfer solutions that can withstand the toughest environments.

Thermoplastic hydraulic hose and fittings

Sinopulse thermoplastic hydraulic hose and fittings allow you to reimagine your design.

Our systems engineering portfolio offers streamlined product configurations, making it easy to find the perfect combination for every application.

Our commitment to innovation includes the design and technical support needed to develop more efficient, safer and effective

Engine and Air conditioning hose and fittings

We offer a variety of fluid transfer products for transportation-related applications such as air brakes, air conditioning and coolant systems, engines and fuel systems. We offer socketless designs and PTFE products, as well as options for specific market segments such as railroads.

Air brake hose and fittings

Explore air brake hoses, Sinopulse tubing, brass crimps and quick disconnect fittings for reliable air system solutions.

Engine and A/C hose, tubing, and assemblies

Sinopulse fuel hoses, tubing, refrigerant and air conditioning fittings for optimum performance.

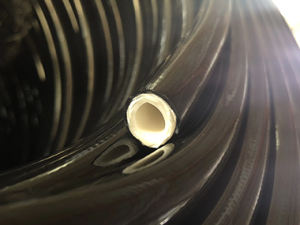

PTFE hose and fittings

Sinopulse offers PTFE hose, crimp and field attachable fittings, and Teflon fluoropolymer hose for a wide variety of applications.

Socketless hose and fittings

Explore socketless hoses, fittings, push-to-connect fittings, and high-quality SAE 100R6 hoses for versatile fluid applications.

Industrial hose and fittings

Every industrial hose application has different requirements, whether high or low pressure, fast or slow transmission speeds, or materials ranging from air to water to hazardous chemicals. Sinopulse has a broad portfolio of industrial hoses to meet a range of markets and applications with unique requirements.

Industrial hose and fittings

Every industrial hose application has different requirements, whether high or low pressure, fast or slow transmission speeds, or materials ranging from air to water to hazardous chemicals.Sinopulse has an extensive portfolio of industrial hoses to meet a range of markets and applications with unique requirements.

Thermoplastic hose and fittings

The Sinopulse thermoplastic hydraulic hose portfolio combines the best of nylon and polyester thermoplastic hose to raise the bar on performance, life and versatility, enabling OEMs to design safer, more efficient systems.

Thermoplastic hydraulic hose, fittings and assemblies

Thermoplastic hose, duplex, non-conductive, 100R7, 100R8.

Connectors and quick disconnect couplings

Our carbon and stainless steel fittings ensure leak-free, high-stress performance and reliable assembly while providing top corrosion resistance. Quick-disconnect fittings exceed ISO standards and provide higher pressures and flow rates to minimize energy loss. Available in carbon steel, stainless steel and brass, our adapters come in a variety of sizes and configurations to meet a wide range of applications.

Adapters and Swivel joints

Sinopulse's precision machined adapters are the perfect fit for any fluid transfer application. Available in carbon steel, stainless steel and brass, our adapters meet or exceed industry standards and come in a variety of sizes and configurations to meet any challen

quick disconnect couplings

Sinopulse quick release couplings feature the latest design innovations to maximize ease of use and system uptime in critical hydraulic, pneumatic and thermal management applications.Sinopulse quick release couplings are made of carbon steel, stainless steel and brass and meet or exceed industry standards.

Hose machines, tools, and accessories

Choose Sinopulse for a full line of hose assembly equipment solutions. Our crimping machines, test benches and cutting equipment help you create quality components. Stay organized with our storage solutions and ensure cleanliness and durability with our accessories.

Machines and machine accessories

Choose Sinopulse for industry-leading hose assembly machines and tools. Our product line includes crimping machines, hydraulic hose saws, marking machines and more. Get quality results with Sinopulse machine components and replacement parts.

Choose Sinopulse for durable, reliable, high-performance fluid hose and hose fittings solutions.