As a professional hydraulic hose manufacturer, this article explains the basics of hydraulic hoses, how to choose the right hydraulic hoses for your application, and their common uses.

What Is a Hydraulic Hose?

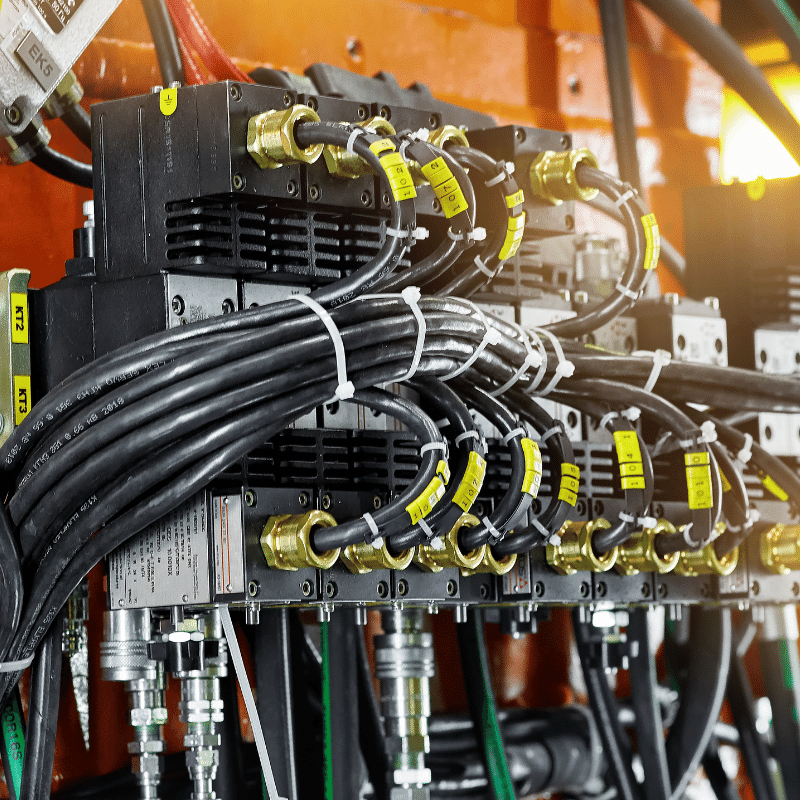

A hydraulic hose is a specialized flexible tube used in commercial and industrial settings. Typically made of rubber with steel wire reinforcement, it consists of multiple layers to ensure strength and durability. These layers include:

- Inner tube: Transports fluid

- Reinforcement layer: Provides pressure resistance

- Outer cover: Protects against environmental damage

Hydraulic hoses transfer pressurized fluid between system components (pumps, valves, cylinders). While semi-rigid, their multi-layer construction balances flexibility with high-pressure performance.

What Is the Application of Hydraulic Hoses?

Like the hose you use to water a garden, hydraulic hoses allow fluid—in this case, hydraulic oil—to flow between components. They act as critical pathways to ensure uninterrupted fluid transfer, keeping hydraulic systems operational. A failed hydraulic hose can shut down entire production lines or disable vital machinery until replaced.

Hydraulic hoses are used across industries, from mining to construction. They power industrial machinery, oil equipment, tank trucks, and sprinkler trucks. Before selecting a hose, identify its specific application and working conditions. For example, hoses exposed to rough surfaces require abrasion-resistant designs.

How to Choose the Right Hydraulic Hose for Your Application

Construction: Used in equipment like cranes, excavators, and bulldozers to power hydraulic cylinders for movement and heavy lifting.

Agriculture: Found in tractors and harvesters to control hydraulic cylinders for attachments like plows and sprayers.

Mining: Drilling rigs and excavators rely on hoses to drive hydraulic motors and cylinders for mechanical operations.

Manufacturing: Powers hydraulic cylinders in presses and injection molding machines for precise equipment control.

Aerospace: Operates hydraulic actuators for landing gear, brakes, and flaps in aircraft.

Automotive: Supports brake systems, power steering, and suspension systems in vehicles.

Marine: Used in ship cranes and winches to power hydraulic cylinders for lifting and movement.

In summary, hydraulic hoses are essential components in hydraulic systems, powering a wide range of industrial machinery and equipment.

Fluids Transported by Hydraulic Hoses

Hydraulic hoses transfer hydraulic fluid to power machinery while also protecting components from wear. Below are common hydraulic fluid types:

Mineral-based fluids – Prevent wear, oxidation, corrosion, and extreme pressure conditions.

Water-based fluids – Fire-resistant due to high water content.

Synthetic-based fluids – Offer fire resistance, low friction, and thermal stability for high-temperature/high-pressure applications.

Common Applications of Hydraulic Hoses

Hydraulic hoses are widely used in:

- Construction equipment: Excavators, dump trucks, loaders, bulldozers, pavers.

- Agricultural machinery: Tractors, harvesters, fertilizer spreaders.

- Snow/ice removal equipment.

- Mining machinery: Drilling rigs, excavators.

- Industrial systems: Assembly lines, presses, robots, hydraulic power units.

Key Hydraulic Hose Applications

Log Splitter Hydraulic Hoses

Log splitters cut wood into logs using sharp blades powered by hydraulic systems. Most log splitters require 1/2-inch hydraulic hoses to transfer fluid and operate efficiently.

Tractor Hydraulic Hoses

Tractors rely on hydraulic hoses (e.g., 3/8-inch, 1/4-inch, or 2-wire braided hoses) to power steering, loaders, and attachments.

High-Pressure Washer Hydraulic Hoses

Designed to handle extreme pressures (up to 4,000 psi), these hoses deliver water for cleaning surfaces. Unlike standard hoses, they prioritize pressure resistance over oil compatibility.

Air Compressor Hydraulic Hoses

Used to transfer pressurized air in compressor systems. Specific hoses are available for air-powered applications.

Dump Trailer Hydraulic Hoses

Dump trailers use hydraulic hoses to lift and transport heavy loads (e.g., containers, barrels). Proper hoses ensure smooth operation during loading/unloading.

Skid-Steer Hydraulic Hoses

Skid-steer loaders depend on durable hoses for construction and landscaping tasks. These hoses support hydraulic systems that power buckets and attachments.

Snowplow Hydraulic Hoses

Snowplows (or snow blowers) require hydraulic hoses to clear snow and ice. These hoses must withstand cold temperatures and frequent movement.

Truck Hydraulic Hoses

Trucks use hydraulic hoses for braking, suspension, and cargo management. We stock OEM-compatible hoses in various sizes for truck maintenance.

Excavator Hydraulic Hoses

Critical for excavator performance, these hoses power digging and lifting functions. Regular replacement prevents leaks and downtime.

Caterpillar® Hydraulic Hoses

Custom hoses meet Caterpillar® machinery specifications, ensuring reliable power transfer in construction and mining equipment.

Purpose and Functions of Hydraulic Hoses

Hydraulic hoses transfer power between components in hydraulic systems. These systems use pressurized fluid to perform mechanical tasks, such as lifting heavy loads or moving large objects. A hydraulic system includes cylinders, motors, pumps, valves, and filters—all connected by hydraulic hoses that transfer high-pressure fluid between parts.

Key Functions

- Power transmission: Move high-pressure fluid (typically hydraulic oil) between components.

- Pressure resistance: Withstand extreme pressure without leaking or bursting.

- Durability: Resist abrasion, weathering, and bending during operation.

- Flexibility: Bend and twist to accommodate machinery movement.

Who Uses Hydraulic Hoses?

Hydraulic hoses are used across industries, including:

- Construction

- Manufacturing

- Agriculture

- Transportation (trucks, rail)

- Automotive

- Industrial machinery

You’ll find them in factories, fleet vehicles, and equipment like excavators or harvesters. For industry-specific applications, visit our Markets page.

Types of Hydraulic Hoses

Hydraulic hoses are broadly categorized into two standards: SAE standards (Society of Automotive Engineers) and EN standards (European Norms). SAE hoses are widely regarded as the industry benchmark and are the most commonly used in many regions. SAE specifications include 16 hose types, each with strict dimensional and performance requirements. Below are the main categories:

1. Braided Hose

- Design: High-pressure hose with single, double, or triple braided steel wire layers.

- Applications: General industrial use for oil- or water-based fluids.

- Temperature range: -40°C to 100°C.

2. Multi-Spiral Hose

- Design: Highly flexible with internal reinforcement for heavy-duty construction and high-pulse applications.

- Applications: Transfers mineral oil, hydraulic fluid, or oil/water emulsions. Common in mining, construction, agriculture, and oil industries.

3. Low-Pressure Hose

- Design: Fabric-braided construction for flexibility (unsuitable for high pressure).

- Applications: Light-duty uses like air transfer, lubrication, or return lines.

4. Stainless Steel Braided Hose

- Design: Single/double stainless steel wire braiding for corrosive environments.

- Applications: Chemical transfer, extreme temperatures/pressures, and vacuum conditions.

5. Thermoplastic Hydraulic Hose

- Design: Two thermoplastic layers with wire/synthetic reinforcement.

- Applications: Low-temperature operations, abrasion-resistant uses (e.g., hydraulic lifting equipment and lubrication lines requiring small outer diameters).

How to choose the right hydraulic hose for your Application

When choosing a hydraulic hose, consider factors such as working pressure, temperature, fluid compatibility, flexibility and environmental conditions. Be sure to review industry standards, manufacturer specifications and seek professional advice to ensure the hose is suitable for your specific application.

Making informed decisions is critical when selecting the right hydraulic hose for your project. The performance and safety of your hydraulic system depends on selecting the right hose to meet the specific needs of your project.

To ensure you choose the right hydraulic hose, you need to consider several factors. First, evaluate the system's operating pressure and temperature requirements. Different projects have different pressure and temperature ranges, so it's critical to select hoses that can handle these conditions without compromising performance.

Next, evaluate the compatibility of the hose material with the fluid being transported. Hydraulic systems use different types of fluids, such as oil, water or synthetic fluids. It is critical to select hoses that are compatible with the specific fluids used in your project to prevent any chemical reactions or degradation.

Another key factor is hose size and length. Sizing should be based on the flow requirements and pressure drop limitations within the system. In addition, make sure that the length of hose chosen is flexible enough not to be excessively slack or stretched.

In addition, consider environmental factors such as abrasion resistance and exposure to chemicals or UV light. If your project involves working in harsh conditions or exposed environments, choose a hose with additional protective features, such as an abrasion-resistant housing or UV stabilizer.

Finally, don't forget industry standards and certifications. Make sure the hydraulic hose you choose meets relevant industry standards, such as SAE (Society of Automotive Engineers) specifications, for optimal performance and safety.

Hydraulic Hoses-SAE100R1 Application

High temperature medium pressure hydraulic oil lines,

antifreeze solutions, air and water. Confirms to SAE100R1/EN853 1SN & ISO 1436-I Specifications.

Hydraulic Hoses-SAE100R2 application

High pressure hydraulic lines, antifreeze solutions, air and water. Conforms to SAE100R2/EN853 2SN & ISO 1436-2 Specifications.

COMPACT HOSE FOR BACKHOE APPLICATION

Rated 1 Million impulse cycles at omega flex configuration. As per ISO 6803 spec. Flex impulse & tight bend makes it suitable for Backhoe loader, other construction & earth mover applications. Reference specs EN 857 2SC & SAE100R16 Specifications.

SAE100R6 application

Hydraulic applications in low pressure lines, return lines & drain lines, Heavy duty transmission oil cooler lines & glycol antifreeze lines. Meet exceeds requirements of SAE100R6 specification.

Hydraulic Hoses-SAE100R3 application

Medium pressure hydraulic lines, fuel oil, antifreeze solutions, air and water. Conforms to SAE100R3 specification.