In pipeline, hydraulic or pneumatic connection systems, choosing the correct threaded hydraulic fittings is of great importance for ensuring the safety, sealing and long-term reliable operation of the system. However, BSP (British Standard Pipe) and NPT (National Pipe Taper) are the two most common used threaded standards, and for those who are new to the fitting thread, it is easy for them to get confused about the differences between them.

What is BSP thread (British Standard Pipe)?

BSP, which stands for British Standard Pipe, originated in the United Kingdom and has become one of main thread standards in plumbing and heating systems worldwide, especially in countries such as Europe, Asia, and Australia.

Feature

The biggest difference between BSP threads and other standards lies in its core technical parameters.

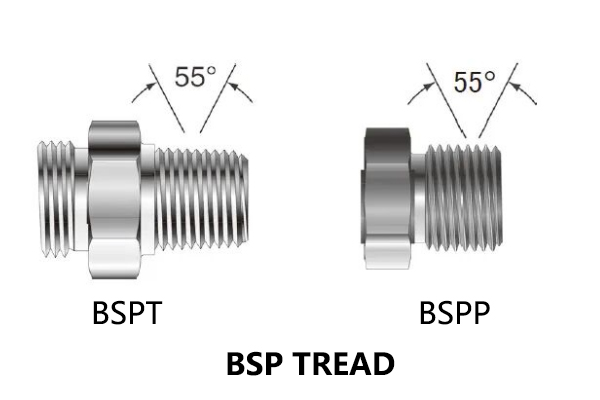

The bsp thread angle is the unique 55° internationally, which is a clear distinction from the 60° angle of the American NPT standard.

The peaks and valleys of the BSP thread are designed as Rounded, making it visually and tactilely smoother than the NPT thread.

Sub-Types

BSPP (British Standard Pipe Parallel): This is the British standard parallel (or straight) pipe thread. Since the thread itself has no taper, it cannot be sealed by compression. Therefore, BSPP connections usually require an external sealing element, such as an O-ring, gasket, or bonded gasket, to form the sealing surface. This design is very conducive to the repeated disassembly and maintenance of the connection.

BSPT (British Standard Pipe Taper): This is the British standard tapered pipe thread. Similar to NPT, the BSPT thread has a gradually narrowing taper. Sealing is achieved by the mutual compression and deformation of the male and female threads when they are tightened. To ensure that the connection does not leak, BSPT connections must be used in conjunction with thread sealants, such as PTFE tape or liquid sealants.

Applications

- Common in plumbing and heating systems in Europe, Asia, Australia, and New Zealand

- Used in hydraulic and pneumatic systems

- Often found in industrial machinery and equipment

BSP connectors are widely used in various fluid transmission fields, including ordinary water and gas pipeline systems, industrial machinery, and marine pressure systems with high sealing requirements. The BSPP thread has the advantage of being easy to assemble and disassemble, making it suitable for systems that require frequent maintenance. Meanwhile, the BSPT provides a more secure mechanical connection through its taper.

What is NPT Thread (American Standard)?

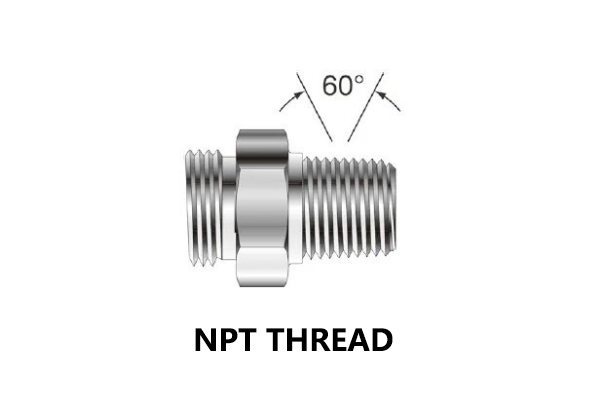

NPT, also named National Pipe Taper, meaning national tapered pipe thread. It is the industry standard for hydraulic, pneumatic and pipeline systems in North America today. NPT is a specification established by the American National Standards Institute (ANSI), and it dominates the vast majority of pipeline connection markets in the United States and Canada.

Feature

The NPT thread is a tapered self-sealing thread. Its thread gradually tightens from the front to the back, forming a cone shape. This causes the male thread to exert pressure on the female thread when being screwed in, thereby forming a seal.

Thread profile angle: NPT threads adopt a 60° profile angle, which is wider than the 55° angle of BSP threads. This is one of the fundamental reasons why the two are incompatible.

Thread shape: The peaks and valleys of NPT threads are designed as Sharp or Flat. When you touch an NPT joint, you will clearly feel that its thread edges are sharper than the rounded BSP threads.

Applications

- Dominant standard in plumbing and heating systems in North America

- Widely used in hydraulic and pneumatic systems

- Common in industrial and commercial applications across various industries

The NPT fittings is highly favored due to its high sealing performance when tightened. They are widely used in pipelines, oil and gas, chemical industries, as well as various hydraulic and pneumatic equipment in North America. The advantage of NPT is that its taper design can provide strong sealing; however, its drawback is that since the seal relies on the compression of the threads, over-tightening can easily damage the threads, potentially causing permanent deformation and causing trouble for subsequent maintenance and replacement.

BSP vs NPT Fittings Difference

Although the BSP and NPT connectors may look similar in appearance, especially at certain sizes, their subtle design differences result in incompatibility. They are not merely a difference in names between "British" and "American" systems, but can also affect whether the fluid system can achieve a safe and reliable seal, ensuring the safety of the system and operation.

Thread Angle

This is the most fundamental difference between the two. The thread angle of NPT thread is 60°, while that of BSP thread is 55°. The difference in angle means that the slope of the side of the thread is completely different. Attempting to screw a 60° NPT thread into a 55° BSP thread will result in the side of the thread not aligning correctly. It can only be squeezed on a very small contact surface, which will inevitably lead to loosening of the connection and severe leakage.

Thread Form

The shapes of the peaks and valleys of the threads also vary significantly. NPT threads adopt a sharp or flat contour design, emphasizing the formation of a firm metal contact seal under conical compression. In contrast, the peaks and valleys of BSP threads are rounded. This design is generally considered to be easier to process during manufacturing and is more dependent on the sealing mechanism corresponding to its sub-type (BSPT or BSPP).

Taper vs. Parallel

The NPT standard almost always uses tapered threads (Taper), which rely mainly on the wedge effect of the threads themselves to achieve sealing. While the BSP standard also includes both tapered (BSPT) and parallel (BSPP) types. The parallel threads of BSPP do not have the self-sealing capability of NPT and BSPT. They must rely on external gaskets or O-rings to complete the sealing.

Threads Per Inch, TPI

Although for certain nominal sizes, the thread pitch per inch (TPI) of NPT and BSP threads may be very close, they are often not exactly the same. For instance, for a 1/2-inch fittings, the TPI of NPT and BSP may only have a slight difference, but it is precisely this subtle pitch disparity that causes them not to mesh correctly when screwed in. The misalignment of the threads can lead to stress concentration at the connection point and failure under pressure. BSP and NPT fittings may have different size designations. Consult a reference chart to compare size markings for the specific fitting you’re working with.

Sealing Methods

NPT (conical) threads achieve self-sealing through the compression between the threads, and they require the use of PTFE tape or sealant to achieve a complete seal. The BSPT (conical) type is also formed into a complete seal through the plastic deformation of the threaded shape. BSPP (parallel threads) requires the use of washers/O-rings to achieve sealing and ensure no leakage. Therefore, it is not feasible to mix NPT and BSP. Any connection that seems to "fit tightly" is merely a superficial phenomenon. Under actual application pressure, due to the misalignment of internal parameters, leakage and failure are inevitable consequences.

BSPP vs NPT

BSPP (British Standard Pipe Parallel) and NPT (National Pipe Taper) are both pipe thread standards, but with key differences:

- BSPP threads are parallel, while NPT threads are tapered.

- Both standards typically rely on sealing compounds for a tight seal.

- BSPP and NPT threads are not compatible and cannot be interchanged.

BSPT Vs NPT

BSPT (British Standard Pipe Taper) and NPT (National Pipe Taper) are both tapered pipe thread standards used to connect pipes and fittings. While they serve a similar purpose, there are key distinctions:

NPT (National Pipe Taper):

- Originates from the United States

- Has a 60-degree included angle

- Tapered 3/4 inch per foot

- Primarily relies on sealing tape or compound

BSPT (British Standard Pipe Taper):

- Originates from the United Kingdom

- Has a 55-degree included angle

- Tapered 1 in 20

- Primarily relies on metal-to-metal contact for sealing

Difference between BSPT and BSPP

The BSP standard encompasses two main types: BSPT and BSPP. Although both belong to the British standard system and share a 55° thread angle, a key difference in their design lies in whether the thread is tapered or not.

BSPT - British Standard Pipe Taper

Design feature: The BSPT threads have a taper (Male and Female). This means that the diameter of the threads gradually decreases from the port towards the inside, similar to the principle of NPT.

Sealing method: Creates a much tighter seal due to the tapered threads. As you screw the fitting together, the threads become increasingly engaged, compressing the fitting and creating a stronger seal. This makes BSPT ideal for a broader range of pressures, including moderate to high-pressure applications. To further enhance the seal, using a sealant like PTFE tape is recommended with BSPT.

Usage: Applicable to situations where permanent or semi-permanent, high mechanical strength connections are required.

Hydraulic and pneumatic systems (where fluids are under moderate to high pressure)

- High-pressure water lines (industrial applications)

- Oil and gas pipelines

- Machinery and equipment requiring secure connections under pressure

BSPP - British Standard Pipe Parallel

Design feature: Features a straight, cylindrical thread with a flat flank. Think of it like a screw that maintains a consistent width throughout its length.

Sealing method: Primarily relies on the threads themselves for sealing. This makes it suitable for low-pressure applications where a leak-proof connection isn’t as critical.

Sealing requirements: For BSPP connections, no sealant is required on the threads (unless it is used as an additional anti-corrosion protection). The key is to ensure that the gasket or O-ring is intact and properly positioned.

Usage: Due to its parallel design, the BSPP thread can be adjusted in direction during tightening without affecting the seal. Therefore, it is particularly suitable for applications where components need to be frequently disassembled, maintained, or direction adjusted, such as pressure gauges, hose connectors, etc.

- Low-pressure plumbing systems (think water supply lines within a house)

- Air conditioning systems (especially for low-pressure refrigerant lines)

- Instrumentation and control systems (where pressure isn’t a major concern)

How to Select the Right BSP or NPT Fittings?

Correctly choosing BSP or NPT fitting is not only about ensuring proper thread matching, but also an engineering decision that affects system performance and long-term reliability. After accurately identifying the thread standard of the existing or required system, the next step is to make the best choice based on your application environment.

Location

This is the simplest and most important decision factor. First, you need to determine the industry standards that the device or installation location you are connecting to follows:

North American market (USA, Canada): Without a doubt, the NPT thread is the preferred choice. This is the default standard in this region and ensures compatibility with locally purchased valves, pumps and pipe fittings.

Global market (Europe, Asia, Australia): In most cases, BSP threads should be chosen. You need to further distinguish whether it is BSPT or BSPP. If the existing system is already in the BSP standard, simply continue to use it and ensure that the taper/parallel type of the new connector is consistent with that of the old fitting.

Application pressure

For high-pressure applications, NPT’s tapered thread and reliance on sealant generally offer a more secure seal.

Existing components

If you’re working with existing plumbing or equipment, ensure the new fitting matches the thread type already present.

By understanding the key differences between BSP and NPT thread fittings, you can ensure a safe and reliable connection in your project. When making the choice, please also consider regional compatibility, application pressure, and the situation of existing fittings.

If you have any doubts about whether the size is suitable or need assistance in finding a fitting solution that meets your specific requirements, please contact our expert team.

As a professional hose fittings manufacturer, Sinopulse offer various sizes and materials of BSP and NPT fittings to meet the needs of different applications. Now, get in touch with us!