Sinopulse is a specialized manufacturer of PTFE hoses, known for producing durable and versatile solutions engineered for exceptional chemical resistance. Our Teflon braided hoses perform reliably across a wide temperature range, making them ideal for challenging industrial environments.

Many people — including some experienced PTFE hose distributors — often confuse PTFE hoses with PTFE tubes. While both are made from the same base material, Polytetrafluoroethylene (PTFE), they differ significantly in structure, purpose, and reinforcement. Below, we’ll explain the key differences between PTFE hoses and PTFE tubes to help you understand each product's unique applications.

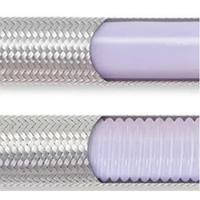

PTFE Hose

What is PTFE hose

A PTFE hose is essentially a PTFE tube that has been reinforced—typically with stainless steel braiding or other materials—to enhance its pressure resistance. Thanks to its unique properties and exceptional resistance to chemicals and high temperatures, it is a preferred choice among engineers and facility managers.

At Sinopulse, we collaborate closely with your team to develop tailored solutions that meet the exact requirements of your application. Choosing the right PTFE hose manufacturer is crucial to ensuring reliable performance in your most demanding fluid transfer systems.

Key Features:

-

Inner layer: PTFE tube

-

Outer reinforcement: stainless steel braid / thermoplastic / textile / other layers

-

Designed for high-pressure and high-stress applications

-

Often used in hydraulic, chemical, or food processing systems

- Size: 1/8 inch to 1-1/2 inches

- Temperature Rating: -55 °C to +210 °C

- Maximum working pressure: 4000 PSI.

Typical Applications:

-

Hydraulic systems

-

Fuel and brake lines

-

Food and beverage processing

-

Chemical transport in industrial plants

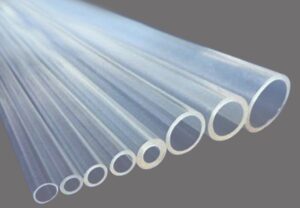

PTFE Tube

What is PTFE tube

A PTFE tube is a pure, extruded or molded hollow cylinder made entirely of PTFE. It is typically flexible but has no reinforcement.

Key Features:

-

100% PTFE material (non-reinforced)

-

Very chemically resistant

-

High-temperature tolerance (typically -70°C to +260°C)

-

Used for transferring pure gases, chemicals, or fluids

-

Typically used in laboratories, medical equipment, or electronics

Typical Applications:

-

Laboratory fluid transfer

-

Wire insulation

-

Medical and pharmaceutical uses

-

Semiconductor industry

Comparison Table:

| Feature | PTFE Tube | PTFE Hose |

|---|---|---|

| Material | Pure PTFE | PTFE core + reinforcement (braid/layers) |

| Pressure Resistance | Low to medium | Medium to very high |

| Flexibility | High (depending on wall) | Medium (varies with reinforcement) |

| Applications | Lab, electronics, medical | Industrial, hydraulic, automotive |

| Cost | Lower | Higher (due to construction complexity) |

R14 PTFE Smoothbore Hose

R14 Convoluted PTFE Hose

Frequently Asked Questions

1. Can PTFE hose withstand extreme temperatures?

Yes, PTFE hose is engineered to perform reliably across a wide temperature range, making it suitable for both high-heat and low-temperature environments.

2. What is the difference between PTFE hose and Teflon hose?

There is no significant difference—PTFE (Polytetrafluoroethylene) is the chemical name, while Teflon is a brand name. The terms are often used interchangeably to describe the same type of hose known for its excellent chemical resistance and flexibility.

3. What applications are PTFE hoses suitable for?

PTFE hoses, including braided Teflon hoses and PTFE tubing, are ideal for use in industries that require high chemical resistance and reliable performance. Common applications include chemical processing, pharmaceuticals, and food production.

4. Can PTFE hose be customized to meet specific industry requirements?

Yes, Sinopulse offers a range of customization options to ensure that our PTFE hoses meet the exact specifications of your application, regardless of industry.

5. How is PTFE tubing used in fluid transfer applications?

PTFE tubing provides a smooth, non-stick, and chemically resistant interior surface, ensuring safe and efficient fluid transfer with minimal risk of contamination or degradation.

6. What gives Sinopulse PTFE hose an advantage over other products on the market?

Sinopulse PTFE hoses are engineered with superior materials and craftsmanship, offering unmatched quality, durability, and reliability. Our products exceed industry standards and are built for the most demanding environments.

Available in solid white or anti-static black, Sinopulse PTFE hoses are capable of withstanding pressures up to 4,000 psi. The braided Teflon construction enhances both flexibility and strength, ensuring long-lasting performance across a wide range of industries.

By choosing Sinopulse, you’re investing in a high-performance solution designed for smooth, efficient, and safe fluid transfer. We take pride in delivering products that offer peace of mind and consistent results, even in the most critical applications.