Hose Manufacturing Process: Component Integration & Production Workflow

At Sinopulse’s production facilities, hydraulic hoses are manufactured through a precision-driven process that integrates specialized components to meet stringent quality standards. The core components include:

Inner Tube: Custom-engineered for chemical compatibility with the conveyed medium.

Reinforcement Layers: Fabric braids or wire spirals/braids that provide structural strength and pressure resistance.

Layer Stock: Bonding material applied between reinforcement layers to prevent friction and ensure cohesion.

Hose Cover: A protective outer layer safeguarding against environmental and operational damage.

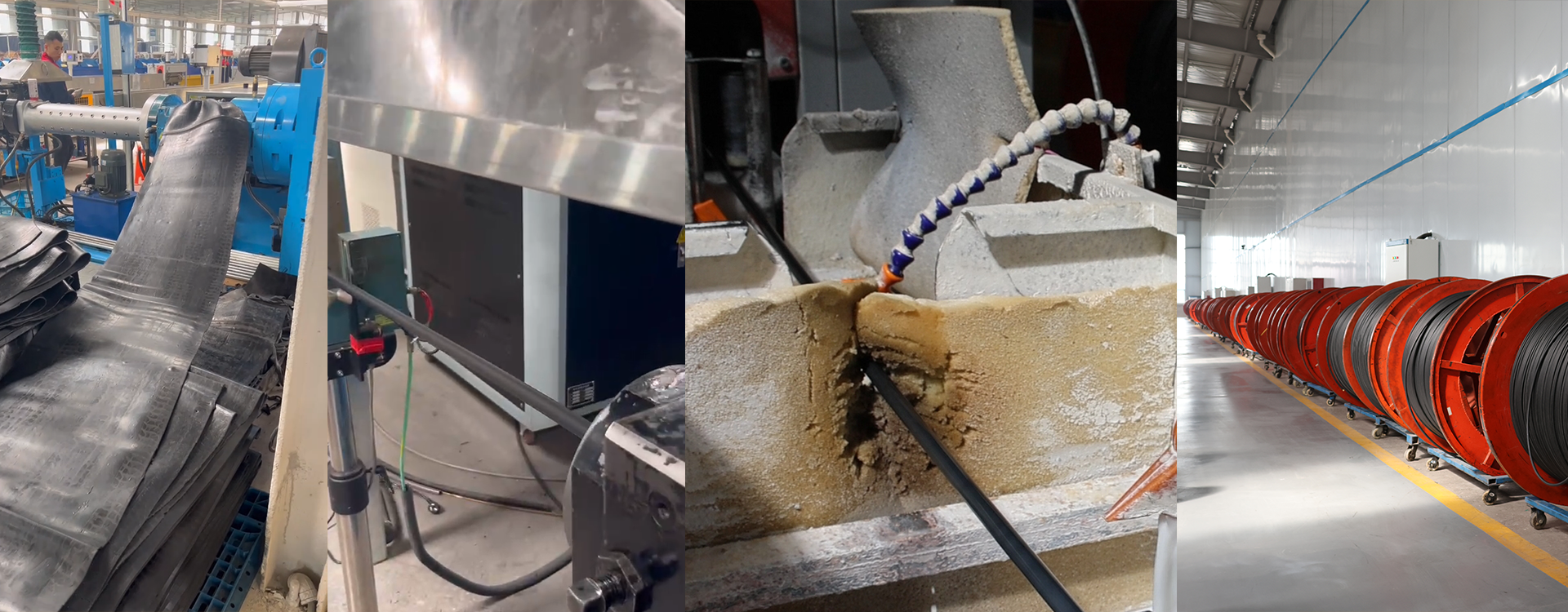

Mandrel Preparation

A mandrel acts as a mold for the inner tube and is removed post-curing. For small-batch production (≤150 ft), rigid mandrels are occasionally used. However, flexible mandrels are standard. Their outer diameter (OD) is extruded to a tolerance of 0.0001 inches to guarantee precise inner hose dimensions. After extrusion, mandrels undergo cooling, coiling, inspection, and preparation for inner tube application.

Inner Tube Production

The selected compound is loaded into an extruder, followed by a test run to verify material quality and wall thickness.

Once validated, the mandrel is fed into the extruder, and the inner tube is directly extruded onto it.

Reinforcement Layer Application

Fabric-Braided Hoses: Spooled fabric is fed into a braiding machine, through which the inner tube (with mandrel intact) passes, creating a braided reinforcement layer.

Wire-Braided/Spiral Hoses: Coated wire is similarly braided or spiraled around the inner tube using specialized machinery.

Layer Stock Integration

Between successive reinforcement layers, proprietary layer stock is applied to bond materials and mitigate interlayer friction. This step is often synchronized with tandem braiding machines for continuous processing.

Hose Covering & Identification

Post-reinforcement, the outer cover is extruded over the assembly. Simultaneously, a ley line is applied (via inkjet, Mylar tape, or embossing) to encode critical data: hose specifications, pressure ratings, manufacturing plant, date code, and application details.

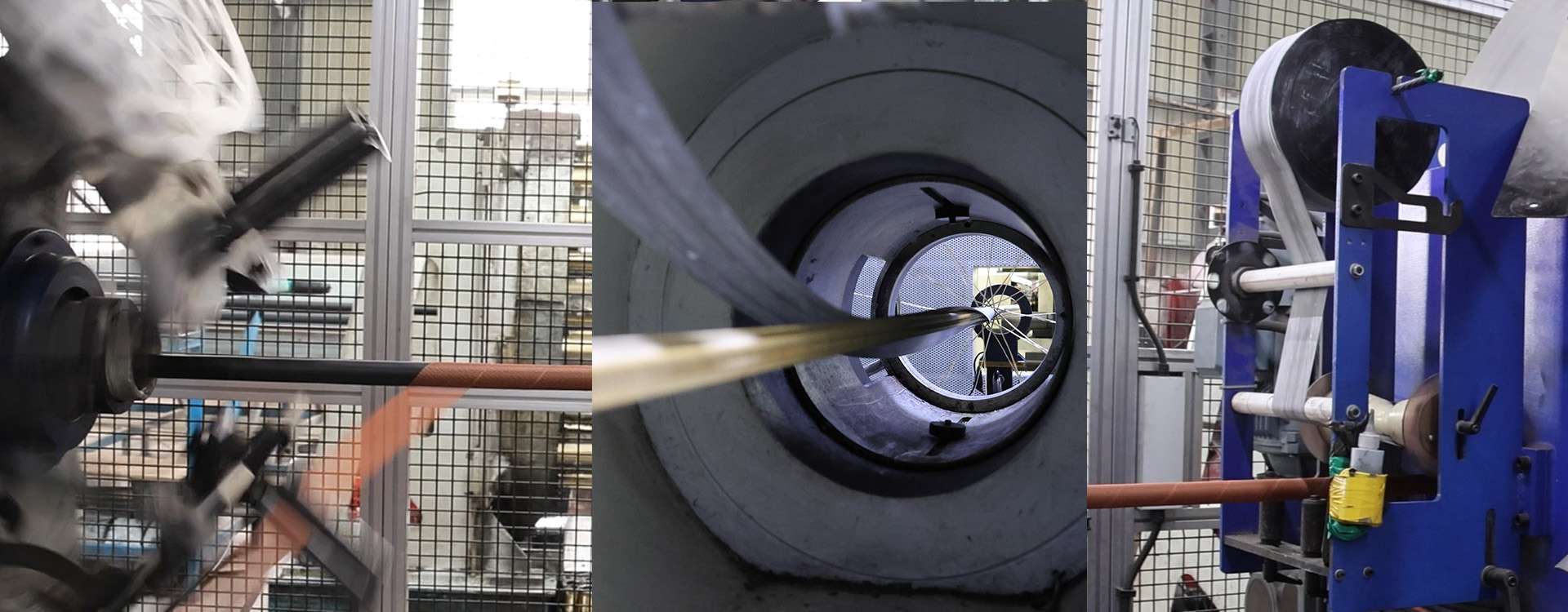

Vulcanization & Finishing

The assembled hose is wrapped in a temporary polymer shell or tape to prevent adhesion during curing.

Vulcanization occurs in pressurized, steam-heated ovens with computer-controlled parameters.

After curing, the temporary wrap is removed, and the mandrel is extracted.

The hose undergoes proof testing at 1.8 working pressure for 60 seconds to validate integrity.

Customization & Packaging

Sinopulse offers specialized outer covers (e.g., braided fabric, wire, or stainless steel) for extreme applications. Finalized hoses are packaged and prepared for distribution to global partners and customers.

Sinopulse is a hydraulic hose factory integrating R&D, production, wholesale and sales. It provides the production, testing and delivery of hydraulic hoses, industrial hoses, connectors, assemblies and other industrial partes for various rubber hoses demand fields domestic and abroad. One-stop service with high quality and fast delivery is available!

Are you looking for the hydraulic hose manufacturer to source the top-rated hydraulic hose, hydraulic hose pipe? Here we are one of the leading hydraulic hose manufacturers in China, and we have the advanced hydraulic hose manufacturing machine to produce the hydraulic hose with big capacity and high quality. We have been in the hydraulic hose industry for over 15 years, and our hydraulic hose products have been exported to over 30 countries, so that we are confident in the manufacturing the best hydraulic hose for your project. For more detailed info, please kindly write to us any time.