Hydraulic Hose Guide

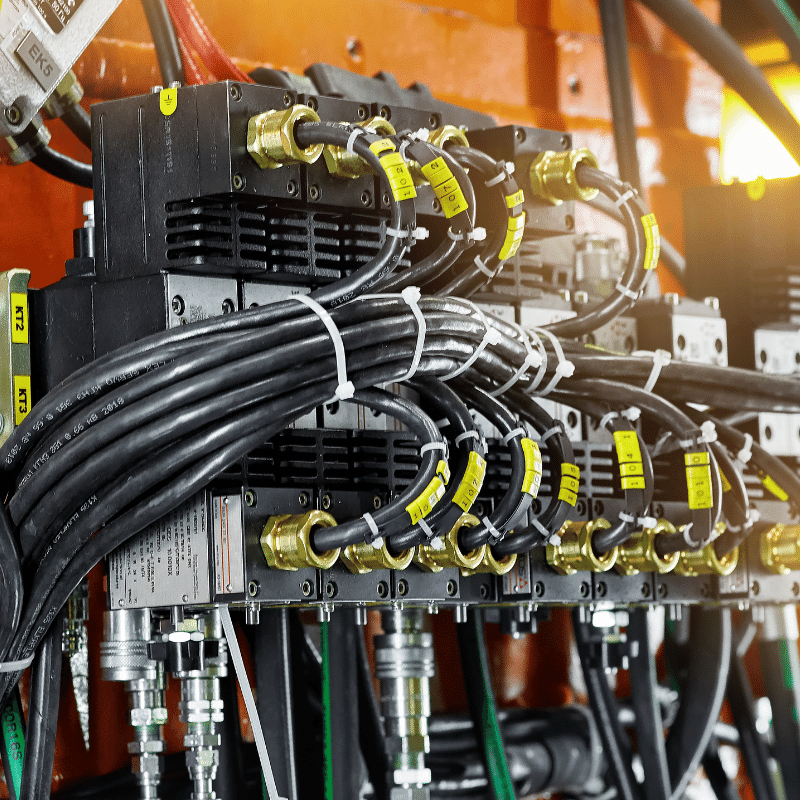

Hydraulic hoses are a important part of modern equipment, powering industries from construction and agriculture to oil & gas and manufacturing. These high-pressure hydraulic hoses convey hydraulic fluid to many hydraulic components in the hydraulic system.

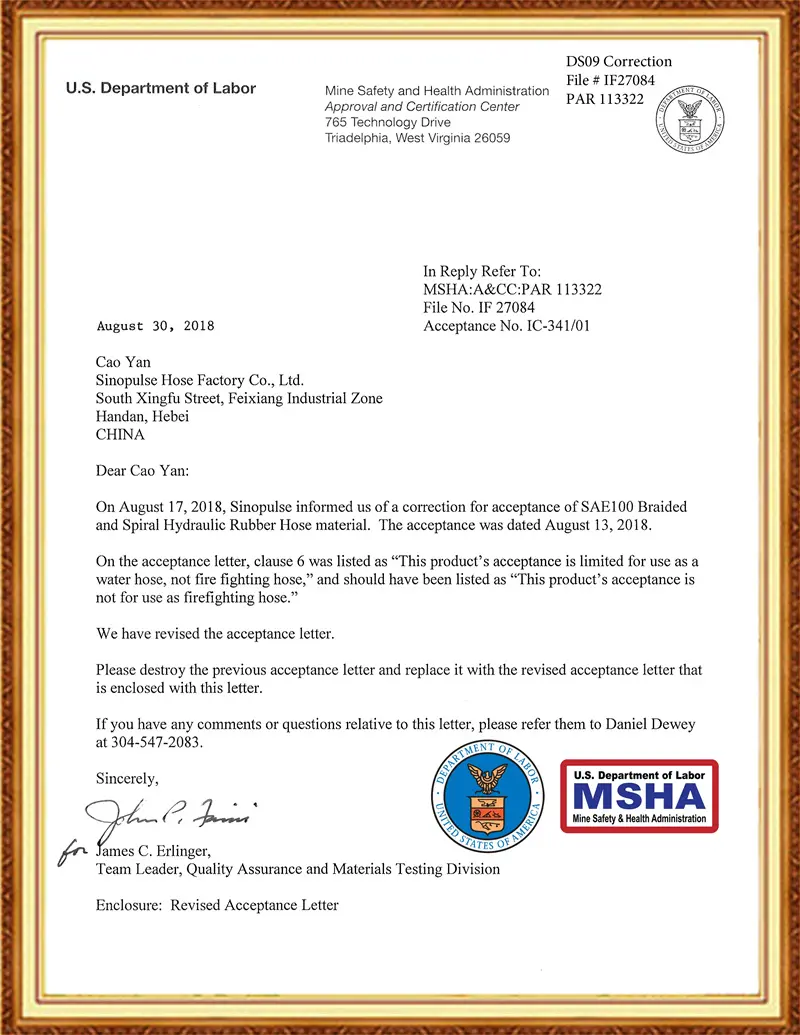

If you need a reliable and professional hydraulic hoses supplier, Sinopulse is the best choice for you. With 20 years of experience in the industry, we are dedicated to providing high-quality hydraulic hoses that meet your specific needs and requirements. Sinopulse hydraulic hoses are made from top-quality materials and have high-pressure, high-temperature, wear, and corrosion resistance characteristics. We provide hydraulic hoses in various sizes, pressures, temperatures, and pH levels to meet different application requirements.

Hydraulic Hoses and Hose Assemblies for Your Industrial Needs

Sinopulse services

What is hydraulic hoses?

High-pressure hydraulic hoses are specifically designed to convey hydraulic fluid to hydraulic components, valves, and actuators.

When selecting a hydraulic hose, the most important consideration is pressure.

Hydraulic hoses Applications

Sinopulse hydraulic hoses are well-used in multiple industries. Some are the following:

- Construction machinery

- Agricultural machinery

- Automotive industry

- Aerospace

- Petrochemical

- Rail traffic

- Port terminal

- Water Resources and Hydropower

Sinopulse Hydraulic hoses and fittings solution

We offer high-pressure hoses and a wide variety of fittings, including both permanent crimp-on and field-attachable types. Our hydraulic hoses are highly flexible and reinforced with multiple layers of steel wire braiding or winding to ensure safe operation under high or ultra-high pressure.

About Sinopulse Custom Hydraulic Hoses Capabilities

Sinopulse has a wide range of capabilities to meet the unique needs of our customers. Our company has more than 20 hydraulic and industrial hose production lines, and a team of experienced engineers who can customize high-quality hydraulic hoses according to your specific requirements.

Sinopulse offers a variety of customization options, including hose size, length, pressure rating, temperature range, and end fittings. Our hoses are available in various materials, including synthetic rubber, thermoplastic, and PTFE, to meet the demands of various applications.

Sinopulse hydraulic hoses are manufactured to meet or exceed industry standards, and we conduct rigorous testing to ensure that they are reliable and durable. We also offer a range of value-added services, including hose assembly, labeling, and packaging, to make the ordering process as easy and convenient as possible for our customers.

Whether you need a single custom hydraulic hose or a large volume order, Sinopulse has the capabilities and expertise to meet your needs.

Sinopulse Hydraulic Hoses for Your Applications

Hydraulic hoses are used in construction equipment, such as excavators, bulldozers, and backhoes, to power hydraulic systems that lift heavy loads and move earth and debris.

Hydraulic hoses are used in farming equipment, such as tractors, harvesters, and sprayers, to power hydraulic systems that operate the machinery.

Hydraulic hoses are used in manufacturing machinery, such as presses, mills, and lathes, to power hydraulic systems that control the machinery's movement and operation.

Hydraulic hoses are used in mining equipment such as loaders, excavators, and drilling rigs to power hydraulic systems that control the movement of the equipment.

Hydraulic hoses are used in transportation equipment, such as trucks, buses, and trains, to power hydraulic systems that operate the brakes, suspension, and steering.

Hydraulic hoses are used in marine equipment such as ships, boats, and offshore platforms to power hydraulic systems that control the movement of the equipment.

Hydraulic hoses are used in oil and gas equipment such as drilling rigs, wellhead control systems, and hydraulic fracturing equipment to power hydraulic systems that control the movement of the equipment.

Related Product

Ultimate Guide to Hydraulic Hose

What is a Hydraulic Hose?

A hydraulic hose is a reinforced flexible hose designed to convey hydraulic fluid to or among hydraulic components, valves, actuators, and tools. They are used in equipment such as excavators, tractors, forklifts, and oil drilling platforms. The hose typically consists of a three-layer structure:

A hydraulic hose is a flexible hose with a reinforcing layer that can transmit hydraulic fluid under high pressure. It is mainly used in heavy equipment such as excavators, tractors, and oil rigs. It has a three-layer structure:

Inner tube: The inner tube is usually made of PTFE, thermoplastic, or synthetic rubber, compatible with the liquid it carries.

Reinforcement: This is made of braided and spiral steel wire or textile cotton thread to enhance the strength of the hydraulic hose.

Outer cover: This needs to prevent abrasion and resist harsh environments.

What types of liquids can a hydraulic hose convey?

There are three main types of liquids that can run through a hydraulic hose, including: Synthetic oil, petroleum oil, and high-water content liquid.

What are the working pressure and burst pressure of a hydraulic hose?

The maximum working pressure is the pressure the hose can handle during normal operation. The burst pressure is generally four times the working pressure; exceeding this pressure value will cause the hose to fail and risk leakage.

What are the types of hydraulic hoses?

Hydraulic hoses are primarily classified by their pressure ratings (high, medium, low), reinforcement design (helical, braided, or spiral), and materials (synthetic rubber, Teflon, or thermoplastics). Each type of hydraulic hose is tailored to specific application requirements

How to Choose the Right Hydraulic Hose

When choosing the right hydraulic hose, many people use the STAMPED method. S stands for the inner diameter size of the hydraulic hose, T for temperature (selecting a hose that exceeds the temperature range will lead to hose failure), A for application, M for the material the hose needs to transport, P for pressure, E for the end fitting, and D for the delivery method. By considering these factors, you will find the appropriate hydraulic hose.

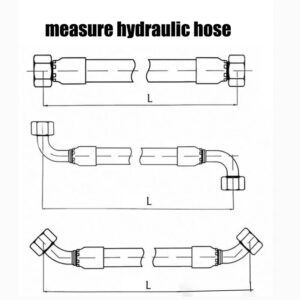

How to correctly size hydraulic hoses:

Measurements hoses should be taken using the end face of the fitting core or the center of the bent fitting core as the reference point. See the image below.

How to Install Hydraulic Hoses?

Hydraulic hoses can be cut to the appropriate length, crimped using a crimping machine, and installed into the system. Their flexibility allows them to bypass other components, saving time when dealing with complex systems with limited access points.

What is a Hydraulic Hose Assembly?

A hydraulic hose assembly is a professionally designed unit composed of hydraulic components, including the following:

A hydraulic hose capable of withstanding the system’s pressure, temperature, and fluid type.

Fittings securely attached to each end of the hose, providing leak-proof connections to pumps, cylinders, valves, or other components.

Adapters, couplings, or clamps are also part of the assembly to ensure compatibility between different thread types, sizes, or connection standards, and to hold the hoses firmly in place.

What are hydraulic hose fittings?

Hydraulic hose fittings are specialized connectors designed to securely connect hoses, pumps, actuators, valves, and other components of a hydraulic system, ensuring pressure-resistant and leak-proof connections for efficient fluid transfer. They come in different materials, sizes, pressure and temperature tolerances, and types of seals to match individual system requirements.

How to Maintain Hydraulic Hoses

Hydraulic hoses require regular inspection and maintenance; otherwise, it can lead to equipment downtime and increased maintenance costs. Check the following areas: abrasions and cracks, leaks or blisters, and loose or corroded fittings. It is recommended to replace hoses before failure.

Why Choose High-Quality Hydraulic Hoses?

High-quality hydraulic hoses typically exceed industry standards in terms of pressure, abrasion resistance, and longevity. While standard hoses meet specifications, a quality hydraulic hose can reduce downtime and long-term costs—making it an ideal choice for critical applications.

Hydraulic Hose, Fittings, and Systems Experts

Need help with hydraulic hoses and fittings? Sinopulse's hydraulics experts are here to support you. Whether you want to know which hose or fitting is best suited for your application, or need a complete hydraulic assembly, our professionals will provide the optimal solution.

We are your trusted experts in hydraulic hoses and fittings. From tubing assemblies to custom hose kits, we have the capability to provide tailored solutions to ensure the reliable performance and longevity of your equipment. If you're unsure what would be best for your application, we can help.