What is JIC fittings?

JIC (Joint Industrial Committee) fitting, according to SAE J514 definition, is a compression joint made of a 37 degree flared seat surface and parallel thread machining. They are usually made of nickel alloy, brass, carbon steel, and stainless steel.

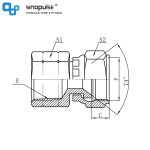

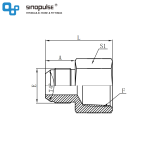

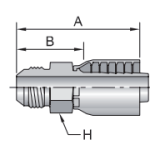

JIC hydraulic fittings are used in hydraulic fluid power systems. Both male and female JIC fittings have a 37-degree flare seating surface to create a reliable metal-to-metal seal. The sealing is achieved through direct contact between the male flare and the female cone seat, which is regarded as a mechanical connection. A complete JIC tubing assembly is made up of three components: the fitting body, flare nut, and sleeve. In the market, this is commonly referred to as a flared fitting, well known for its performance in high-pressure hydraulic applications.

JIC fittings body without the sleeve and nut is often used as a hose adapter for hydraulic rubber hoses. It direct connect to the hose assembly female swivel end. The JIC fittings nut and body are standard components, and they could work with both metric and BST hoses, the JIC fittings sleeve is a component that size based on the hose’s outer diameter. If you need dependable, versatile, and leak-proof hydraulic fittings, JIC hydraulic fittings are a good choice for you.

Advantages of Using JIC Hydraulic Fittings

From our experience running a hydraulic fittings production line, JIC hydraulic fittings are honestly one of the most practical choices for a wide range of systems.

- Easy to get, easy to use – Because JIC fittings are so common, you rarely run into sourcing issues. In our factory, we keep a steady stock for fast replacement, and we’ve seen how having readily available fittings keeps machines running without unexpected downtime.

- Lots of options that actually work – Over the years, we’ve produced JIC fittings in countless sizes, shapes, and materials. This variety isn’t just for show—it allows us to match the right fitting to the exact pressure, temperature, or fluid type a client needs. That flexibility is a big reason why engineers keep coming back to JIC.

- Swap them without worries – Their SAE-compatible dimensions mean you can replace or interchange fittings without second-guessing. In our daily operations, that reliability saves a lot of headaches, especially when servicing hydraulic systems in the field.

- Handles heat like a champ – Because JIC fittings don’t rely on O-rings, they stand up much better in high-temperature environments. We’ve tested them under extreme conditions, and they hold their seal even when the system is running hot, which is critical for heavy machinery.

- Reusable and installation-friendly – One thing we always highlight to our clients: JIC fittings can be disconnected and reconnected multiple times without bending or leaking. In our assembly line, this makes installation and maintenance smoother, and pairing a male JIC with a female swivel really helps align the system without stress.

Disadvantages of Using JIC Hydraulic Fittings

While JIC hydraulic fittings are used widely and have many advantages, there are also some disadvantages:

In high vibration applications, JIC fittings could not provide the required pressure rating. It is a limitation to seal by Metal-to-metal. The 37-degree flare metal-to-metal sealing design restricts JIC fittings mainly to hydraulic applications, making them not very suitable for extremely demanding systems. You cannot over-tighten them; excessive tightening will cause flare damage and cracking, leading to clamping force loss and potential sealing failure.

How JIC Hydraulic Fitting Seals Affect Temperature Rating

JIC hydraulic fitting temperature performance depends on its material and surface protection type. Different materials offer different temperature ratings:

Stainless Steel SS316 JIC hydraulic fitting and Carbon Steel JIC hydraulic fitting temperature ratings from -60 °C to 200 °C

And Brass Carbon JIC hydraulic fitting temperature ratings from -45 °C to 175 °C

By selecting the right material, JIC hydraulic fittings can maintain reliable sealing performance in a wide range of operating applications.

How to Tighten JIC Fittings? – Installation Guide

Installing JIC fittings can be done in four simple steps:

To install JIC fittings, you need to fully check them. Check the JIC fitting body and sealing surfaces for contamination, scratches, or damage.At the same time, you may cut the hose to the required length and flare the hose end to a 37° angle before assembly.

after check, you can apply lubricant (such as hydraulic oil) on the threads and across the entire flared surface. This helps reduce galling and smooth tightening process.

next you coulg Insert the nut and sleeve onto the hose end connection. align the components through hand, then rotate the flare nut until the sealing surfaces fully engage. you made it install tightly and quickly.

FAQ About Sinopulse JIC Hydraulic Fittings

1. What is a JIC hydraulic fitting?

JIC fittings accede to SAE J514 and ISO 8434-2 standards. JIC fitting parts include a sleeve, nut, and body, with a 37-degree flared seating surface. These fittings are referred to as flared fittings. They are often used in various sectors, particularly in high-pressure applications.

2. What is the difference between JIC and AN fittings?

JIC and AN fittings both have a 37° flare, but AN fittings are meet rigorous aerospace and military standards, while JIC hydraulic fittings meet SAE J514 standard, so AN fittings is more strict in standard. JIC and AN fittings are not functionally interchangeable; you need to carefully identify connections to ensure a leak-proof seal.

3. What is the difference between JIC and NPT fittings?

JIC and NPT threads are two different thread options for hydraulic systems. JIC hydraulic fittings have a metal-to-metal 37° flare seal, and NPT fittings have tapered threads and need thread sealant. JIC fittings are easy to reuse and assemble, and often provide reliable sealing. Sinopulse produces both JIC and NPT fittings for different hydraulic system compatibility.

4. How do I know my JIC fitting size?

The size of a JIC hydraulic fitting is based on the outside diameter (OD) of the tube. Dash sizes are measured in sixteenths of an inch; for instance, a -08 fitting is compatible with a 1/2" tube. Sinopulse offers a comprehensive selection of JIC fitting sizes, allowing for the appropriate fitting selection for your hydraulic system.

5. How JIC fittings seal

The male and female ends of a JIC fitting each have a 37-degree flare seat. When the male flare and female tapered ferrule are connected, this creates a sealed connection.

6. How to measure JIC hydraulic fittings?

To measure JIC hydraulic fitting, if you want to measure male joints, you should determin the outer diameter (OD) of the pipe or hose, and if female joints, you should determine the hose inner diameter (ID) needs. you can use a thread gauge or caliper to measure the overall diameter and thread spacing . This measurement result will help you determine the standard of your JIC fitting - metric or BST standards. Many JIC hydraulic fittings Manufacturers provide fitting dimension sheets and technical support to assist customers in identifying and selecting suitable fittings, you can ask them for the technical support .

7. What does JIC mean in hydraulic fittings?

JIC full name is Joint Industry Council (JIC). it is a standardizing 37° flare fitting and used in industrial and mobile hydraulic systems.

8. Why do JIC fittings have a 37-degree flare seat?

The 37° flare makes a reliable metal-to-metal seal for high-pressure hydraulic systems. This design makes it easy to assemble and disconnect without damaging the sealing surface. It does not need for Teflon tape or hose thread sealant, is ideal for preventing leaks and can be used in high-pressure applications.

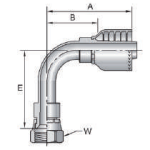

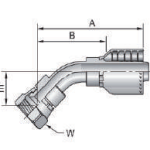

9. What are the types of JIC hydraulic fittings?

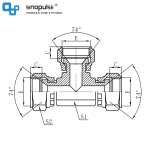

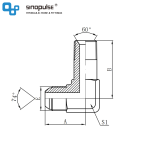

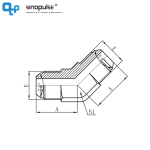

There are many types of JIC hydraulic fittings, including straight pipes, 45 ° and 90 ° elbows, tees, bulkhead fittings, swivel fittings, and adapters with other thread types such as NPT or BSP. The rich variety of products ensures its compatibility with various hydraulic and fluid power systems.

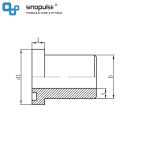

- JIC x BSPP Male Connector w ED Seal (M x M)

- JIC x NPT Female Connector

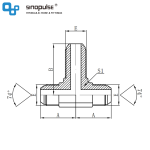

- JIC Tee (M x M x M)

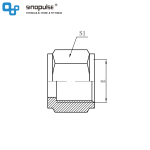

- JIC Nut

- JIC x JIC 45 degree Elbow

- JIC x BSPP 90 degree Positionable Elbow

- JIC x NPT 45 degree Elbow

- JIC Swivel x NPT Female Connector

- JIC Swivel Elbow

- JIC Bulkhead

- JIC Female Swivel x BSPP Male

- JIC x NPT Male Connector (M x M)

- JIC x JIC Union (M x M)

- JIC x JIC Red Union (M x M)

- JIC Swivel ( M x F )

- JIC Female Swivel x BSPP Male

- JIC x BSPP Male Connector 60 degree Cone