In industrial, hydraulic, pneumatic and daily hose line applications, hose fittings and couplings are key components that ensure the safe and efficient transmission of fluids such as water, oil and gas. However, among the numerous coupling standards, NPSM (National Pipe Straight Mechanical, National Standard Straight Thread Mechanical Connection) and NPT (National Pipe Taper, National Standard Taper Thread) standards, both originated from the United States, often confuse purchasers and engineers.

Both follow a 60-degree thread angle and the same pitch (threads per inch), but a minor design difference - straight versus tapered - determines their sealing methods, pressure ratings, and applicable scenarios. Confusion between these two types of threads is one of the main causes of fluid system leaks, downtime, and potential safety risks.

This article will serve as your professional purchasing guide for NPSM and NPT threaded hose fittings. We will provide you with a comprehensive and easy-to-understand analysis covering thread types, sealing mechanisms, pressure suitability, advantages and disadvantages, as well as purchasing considerations. Our aim is to help you clearly understand the essential differences between NPSM and NPT, and ensure that you make correct, safe, and cost-effective choices in any fluid connection application.

|

|

|

NPSM Threads Overview

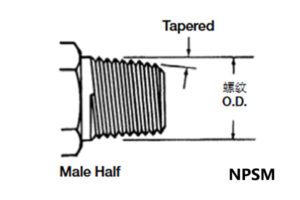

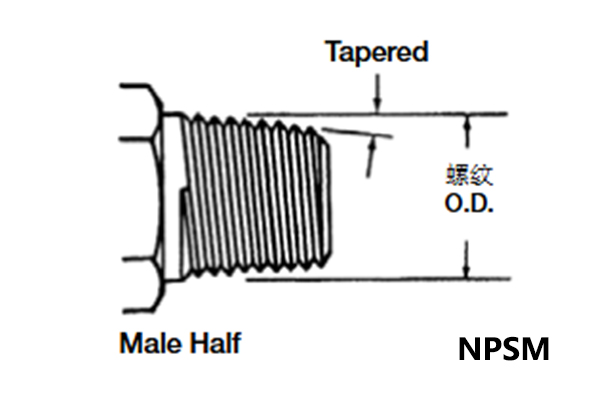

NPSM threads, also called National Pipe Straight Mechanical threads. They are a type of straight pipe thread that does not need taper to thread. Unlike tapered threads, NPSM threads maintain a consistent diameter throughout their length, which allows for a mechanical fit to achieve pressure tight seal.

Features

NPSM Threads are straight threads, which means the thread diameter is uniform and there is no taper. They provide a stable connection for the equipment and can be easily screwed in and out quickly and conveniently.

At the same time, its sealing type is not self-sealing and relies on external sealing components, such as O-rings, washers, or mating metal cones/spherical seats.

Furthermore, it cannot directly seal with NPT male threads; it is generally used in conjunction with NPSM female threads or NPTF threaded caps with seats.

Application

NPSM thread fittings are convenient for assembly and reliable mechanically, so you can use them in many applications:

NPSM threads are the most common in medium- and low-pressure hydraulic systems, as they ensure precise and reliable connections. and they could maintain system pressure and prevent leaks.

You also use NPSM threaded fittings in pneumatic systems; airtight seals are necessary to ensure efficient operation.

In automotive applications, NPSM threads are often used to connect fuel lines, braking systems, and other critical components that need reliable and leak-free connections.

NPSM threads are commonly found in hydraulic pumps and cylinders, ensuring secure connections that withstand high

pressures.

Advantages

Firstly, they are easy to install. They can be quickly and easily assembled with basic tools and forces to the hose, which can significantly reduce the installation time cost and labor cost. If you select the appropriate O-ring and gasket, the sealing performance of it will be very reliable, enabling a leak-free connection. Moreover, it can be reused without affecting the sealing performance of the components themselves. Therefore, it is highly suitable for use in systems that require repeated disassembly and assembly, and is widely applied.

Disadvantages

NPSM thread fittings require an O-ring or a gasket for sealing; otherwise, it cannot form a leak-free connection. Moreover, due to the need for these external seals, in extreme temperature or highly corrosive chemical environments, there will be situations where the seals degrade and are chemically eroded. This poses a risk of leakage. During daily maintenance, not only do we need to inspect and maintain the NPSM components, but we also need to check and maintain the seals, which poses a relatively heavy maintenance burden. Its most suitable application lies in medium and high voltage scenarios. However, it is not applicable to systems that require extremely high pressure.

Installation

NPSM is a straight thread. Its sealing relies on external components. Before installing the NPSM fitting, you must check its sealing components.

Make sure the O-ring or gasket is clean, intact, and properly placed inside the joint seat. Any dust or damage will compromise the seal. When screwing the NPSM joint in place, you don't need to exert too much force. Tighten it enough to compress the sealing element and create metal contact. Since there is no tapered compression, the risk of over-tightening is low, but please avoid applying unnecessary stress to the threads.

If your NPSM connector has an adjustable nut, it will enable you to easily align it in a confined space.

NPT Threads Overview

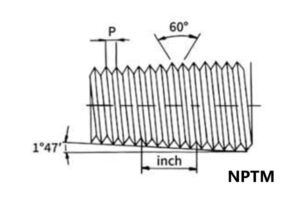

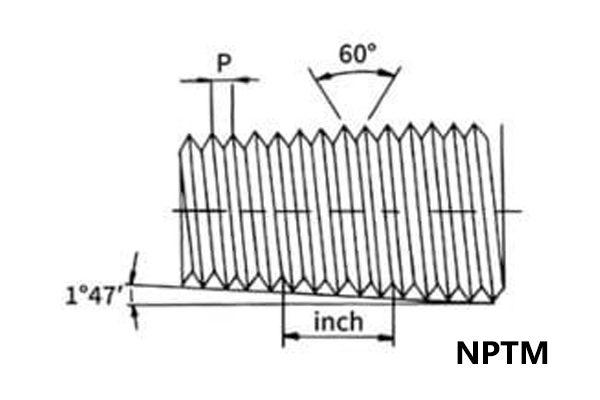

The NPT thread, or the American National Pipe Thread, is a widely used pipe thread in North America. Its thread has a taper, with a taper of 1°47'24" (1.7899°), forming a 1/16 taper over one inch in length. This taper design helps to achieve a tight seal through the interference fit between the male and female threads. As the threads advance, they become tighter, creating a seal through the deformation of the threads.

Feature

NPT thread is a tapered thread. This means that the diameter of the thread gradually becomes smaller. When the male thread and the female thread are tightened, the taper will cause intense compression and interference fit, the thread will undergo slight deformation, thereby forming a tight, leak-free metal-to-metal seal, achieving self-sealing.

Usually, NPT threads require the use of thread sealants, such as Teflon tape or pipe sealant, to ensure that the connection does not leak.

Application

NPT threads not only have excellent sealing performance in high-pressure applications, but also are widely used. For instance, in oil and gas pipelines, as well as on drilling equipment at the mine site, you will encounter this type of threaded connection. At the same time, it can also play a reliable sealing role in pipes and water supply systems.

Advantages

The tapered design of NPT thread enables self-sealing in high-pressure environments through the use of the thread. Therefore, it is different from the NPSM thread. It does not require O-rings or gaskets to achieve a leak-free connection. Because he didn't need additional sealing components, the cost was relatively low and it was widely applied.

Disadvantage

As it is a tapered thread, the main sealing relies on the self-sealing mechanism of the thread deformation. Therefore, it is difficult to achieve disassembly and assembly, and it cannot be repeatedly assembled and disassembled, which will lead to the risk of leakage. When installing NPT threaded joints, do not tighten them too tightly as this can cause the joints to be damaged. Also, when using TEFLON tape, proper operation is necessary; otherwise, the integrity of the seal will be compromised. Therefore, installing NPT also requires experience and skills. The compatibility of the NPT thread is also very poor. Without using an adapter, it will be restricted to being used in systems that require different types of threads.

Installation

NPT is a tapered thread and the installation process requires greater care to avoid damage.

Before tightening, it is necessary to apply thread sealant to the NPT male thread. This is usually PTFE tape (sleeve) or pipe sealant. The function of the sealant is to fill the tiny spiral paths between the threads to achieve a perfect sealing effect. Wrap the tape along the thread direction, usually 2 to 3 turns are sufficient.

The key to installing NPT joints lies in controlling the torque. When tightening, you will feel the resistance gradually increasing. Once the required tightness is achieved, stop immediately. Do not over-tighten. Over-tightening will permanently damage the threaded conical surface, making it impossible to use again in the future, and even potentially cracking the parent fittings.

Differences between NPSM and NPT

To make the right purchasing decision, you must understand the fundamental differences between NPSM and NPT - the shape of the threads and the sealing method.

Thread shape: straight and tapered

The NPSM thread is straight, or rather, parallel. From one end to the other, its diameter remains constant. This ensures that it is mainly a mechanical connection. You can imagine it as the fit between a nut and a bolt. Its main function is to fix, rather than to seal.

In contrast, the NPT thread is tapered. The thread gradually narrows along the axis. It is this 1°47' taper that gives NPT its unique sealing capability. The conical design means that it serves both as a mechanical connection and the key to fluid sealing.

Sealing method: Self-sealing and O-rings, gaskets sealing

NPT threads are self-sealing. When you screw the male thread into the female thread, the tapered thread will perform an interference fit. The metal threads are forced to be pressed together. This compression and the slight deformation of the threads form a leak-proof barrier. Although it is self-sealing, you almost always need PTFE tape or sealant to block the spiral channel to ensure a perfect seal.

The NPSM threads do not self-seal. Straight threads cannot achieve leak prevention through tightening. The sealing function of NPSM completely relies on external components. You must use O-rings, gaskets, or the sealing surfaces inside the joints to prevent fluid leakage. Therefore, if you forget to install the gaskets or O-rings, leakage is inevitable.

Pressure and assembly

Due to the strong internal pressure generated by the conical design, NPT joints can usually withstand higher working pressures. They are dominant in heavy industry and high-pressure fluid systems. However, this compression also brings risks. If tightened too tightly, the threads may be damaged.

The NPSM connector is typically suitable for medium and low-pressure environments. Due to the absence of threaded extrusion, it is easier to install and remove. For mechanical systems that require frequent inspection and component replacement, NPSM offers greater convenience and a lower risk of thread damage.

Compatibility Warning

Please bear in mind: NPT and NPSM threads are incompatible. Although in some cases an NPSM female connector can accept an NPT male thread, this is by no means an ideal or reliable combination, especially not for high-pressure systems. It is incorrect to directly insert an NPSM male thread into an NPT female thread, and this is very likely to cause leakage or damage to the threads.

Choose the right thread

After understanding the differences between NPT and NPSM threads, one must be able to make the correct choice to ensure the safety and efficiency of the system.

Your choice must be based on the application. The first thing to consider is the working pressure of the system. If your fluid system is under high pressure, such as a high-pressure hydraulic hose pipeline, you will almost definitely have to choose NPT tapered threads. Only its compression seal can withstand the high-pressure load. For low-pressure or medium-pressure systems, you will have more options.

Next, the frequency of maintenance needs to be evaluated. If you need to frequently disassemble and reassemble the hose, the NPSM straight thread is a more ideal choice. Its straight thread design can protect the joint and reduce wear. If the connection is relatively permanent and does not need to be touched for a long time, the reliable sealing advantage of the NPT thread will become prominent.

When purchasing, be cautious of the labeling traps related to thread sizes. The dimensions indicated on the connection, such as 1/2" or 3/4", are the nominal pipe size (NPS). They are not the actual outer diameter of the thread. Do not measure the outer diameter directly with a ruler. This can easily lead you to purchase the wrong size.

The correct approach is to use a thread gauge. This is a professional tool used to measure the number of threads per inch (TPI). By measuring TPI and the shape of the threads, you can accurately identify the required specifications. Dimension matching is the foundation of a secure seal.

When purchasing, please clearly inform the supplier of the type of thread and the nominal size you require. Also, when choosing the material of the fittings, consider the type of fluid being transported and the working environment temperature. The corrosion and temperature resistance of the material (such as stainless steel, brass) are equally important as the thread type. A safe and reliable system begins with accurate procurement.

The NPSM thread offers easy assembly and reliable sealing through external seals, while the NPT thread provides a strong pressure-sealing connection through thread deformation.

Choosing the correct thread type of fittings can ensure system reliability, safety, and performance. For further information and detailed specifications, please contact Sinopulse fitting expert. We will help you choose right fitting threads.