What is rubber hose

A rubber hose is a flexible, hollow tube designed to transport fluids from one point to another. Typically cylindrical in shape, hoses are essential for moving air or gases through liquids, or liquids through air or gas environments. Also referred to as tubing or piping, rubber hoses are widely used across a variety of industries.

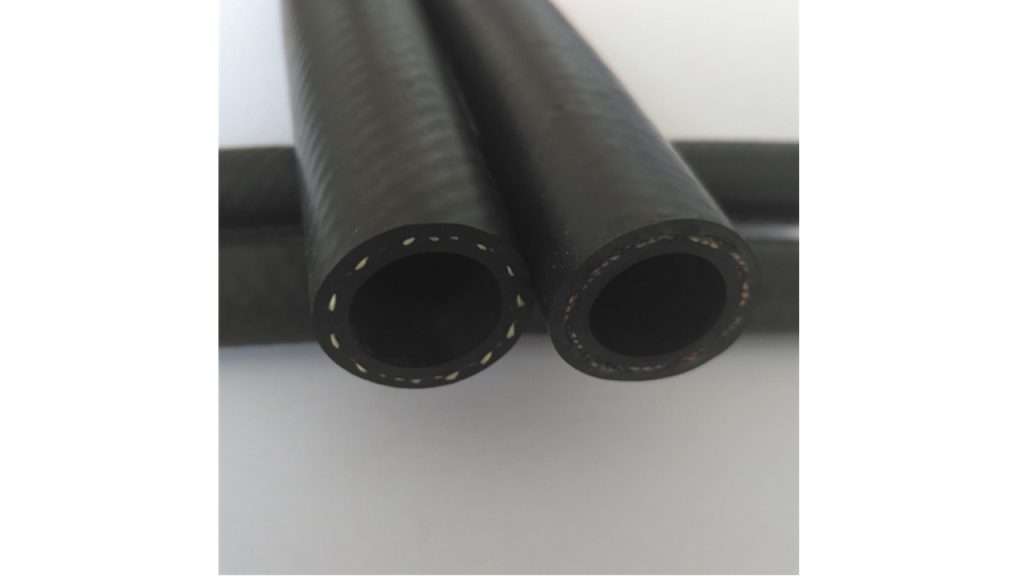

Manufactured through an advanced extrusion process, our rubber hoses are engineered to meet the demands of fluid transfer applications, ensuring durability, flexibility, and reliable performance. Special attention is given to the quality of the rubber material to guarantee excellent resistance under different working conditions.

Among all types, silicone hoses are particularly popular due to their outstanding heat resistance, flexibility, and long service life.

Sinopulse Hose Factory was established in 2011, specializing in the research, development, and manufacturing of rubber and industrial hoses. We operate in strict accordance with ISO 9001:2015 standards to ensure the highest quality products.

Our factory covers 70,000 square meters and employs over 300 skilled workers. We are equipped with a state-of-the-art Rubber Hose R&D Center and a fully equipped Testing Center to support continuous innovation and quality assurance.

Sinopulse has successfully passed SGS and CE certifications, demonstrating our commitment to quality and safety. Today, our products are widely exported to international markets, including the United States, Europe, Japan, South America, and many other regions.

Features of Rubber Hoses

Rubber hoses must meet a wide range of requirements depending on the type of hose, the materials they carry, and the demands on both the inner lining and outer cover. A single hose may include several different rubber compounds, carefully formulated to give each layer its specific properties.

One of the most important factors in rubber hose design is achieving extremely high adhesion between layers, which is essential for maximum fatigue resistance. Key characteristics of rubber hoses include oil and fluid resistance, high resistance to aromatic hydrocarbons, excellent heat resistance, outstanding fatigue durability, and strong ozone resistance.

Applications

Rubber hoses are widely used across many industries. Typical applications include:

-

General Purpose: Versatile hoses for everyday industrial and commercial uses.

-

Agriculture: Used for irrigation, spraying, and fluid transfer in farming operations.

-

Aerospace: Specialized hoses for high-performance aircraft systems.

-

Chemical Handling: Designed to safely transport aggressive chemicals and corrosive materials.

-

Construction: Heavy-duty hoses for water supply, dewatering, and equipment operation.

-

Coolant Systems: For transferring coolant fluids in engines and machinery.

-

Cryogenic Applications: Engineered to perform reliably at extremely low temperatures.

-

Discharge Operations: Used for unloading water, slurry, and other fluids.

-

Exhaust Systems: Heat-resistant hoses for carrying exhaust gases away from engines.

-

Fire Protection: Hoses designed for firefighting and emergency response systems.

-

Food and Beverage Processing: Made with FDA-approved materials for safe food handling.

-

Fresh Air Supply: Provides clean air for ventilation and breathing systems.

-

Gardening and Landscaping: Durable hoses for watering, landscaping, and maintenance.

-

Heavy Industry: High-strength hoses for mining, manufacturing, and large-scale industrial applications.

-

HVAC Systems: For heating, ventilation, and air conditioning fluid transport.

-

Marine Applications: Saltwater-resistant hoses for ships, docks, and offshore platforms.

-

Medical and Pharmaceutical Use: Precision hoses for clean, sterile fluid and gas transfer.

-

Oil and Fuel Transfer: Built for safe transport of petroleum products and fuels.

Our Industrial hose have been widely used in Agriculture, Construction, Automotive, Dredging, Mining, Oil & Gas, Shipyard, Tank Truck and Welding.

Types of Rubber Hoses in Industrial Applications

-

Fuel Hoses:

To control and reduce hydrocarbon emissions, fuel hoses must have extremely low fuel permeability. Blended fuels containing ethanol or methanol require hoses with high resistance to polar solvents. The addition of carbon black in rubber compounds helps decrease gasoline permeability and minimize solvent swelling. -

Radiator Hoses:

Radiator hoses are designed to withstand high-temperature coolant fluids, ensuring reliable engine performance under extreme heat conditions. -

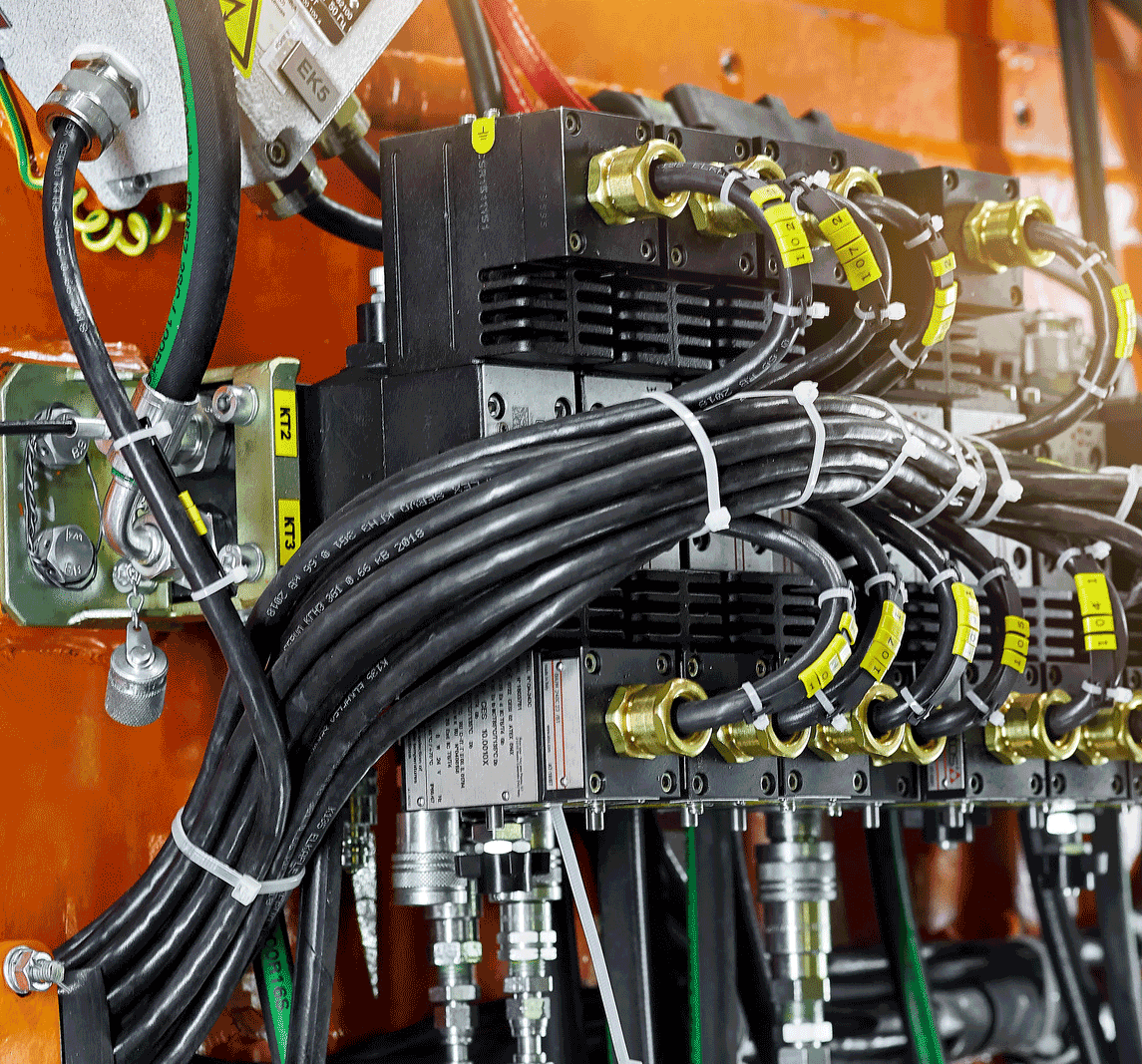

Industrial Hoses:

Industrial hoses cover a broad range of applications, including water and steam hoses, air hoses, petroleum hoses, refrigerant hoses, and chemical hoses. In these applications, strength, as well as resistance to solvents and chemicals, are critical performance requirements. -

Fire Hoses:

Fire hoses are among the most commonly used hoses in industrial settings, widely found in fire stations and emergency services. The inner lining is made of waterproof rubber compounds tailored for its intended use, while the outer layer is made of rubber offering excellent heat and abrasion resistance. -

Garden Hoses:

Designed for watering plants in gardens and lawns, or supplying water to sprinklers for irrigation purposes. -

Air Hoses:

Used in underwater diving to deliver breathable air from the surface or from air tanks. -

Automotive Hoses:

Automotive hoses are used to transport fluids within vehicles for lubrication, cooling, or hydraulic systems, ensuring smooth and reliable operation.

Rubber Hose Market

The rubber hose market refers to the market for hoses made from rubber. Rubber hoses are used in a variety of applications, including for conveying water, air, oil, and other substances. They are used in industries such as agriculture, construction, automotive, and manufacturing, among others. The demand for rubber hoses is driven by the growth in these industries, as well as by advances in technology and the development of new types of rubber hoses that are more durable, flexible, and resistant to heat and chemicals.

The global rubber hose market is expected to grow at a CAGR (Compound annual growth rate) of 3.5% during the forecast period (2020-2025). The major factors driving the growth of the market are the growing demand from the automotive and construction industries and the increasing demand for high-performance hoses. However, the volatile raw material prices and the stringent environmental regulations are the major challenges to market growth.

Rubber Hose Buying Tips

When purchasing rubber hoses, consider the following factors:

Design Specifications

-

Measurement Units: Hoses can be specified using imperial units (such as inches or fractional inches) or metric units (such as millimeters or centimeters).

-

Inner Diameter (ID): The internal width of the hose.

-

Outer Diameter (OD): The external width, typically used for corrugated or convoluted hoses.

Performance Specifications

-

Working Pressure: The maximum pressure the hose is designed to handle during operation.

-

Maximum Vacuum Rating: Measured in inches or millimeters of mercury (Hg) below one atmosphere, indicating the hose's vacuum capability.

-

Minimum Bend Radius: The smallest radius the hose can be bent without causing damage, determined by allowable cross-section deformation and the mechanical limits of any reinforcement layers.

-

Temperature Range: The range of environmental temperatures the hose is designed to operate within.

Construction Options

-

Reinforcement: Incorporates strengthening elements to enhance durability and pressure resistance.

-

Coiling: Designed for improved flexibility and retraction capabilities.

-

Corrugated or Convoluted Design: Features ridges, folds, or spiral wrapping to improve flexibility and compression resistance.

-

Articulated Sections: Made of rigid hose parts connected by movable or articulated joints for enhanced positioning.

-

Multi-Component Construction: Consists of multiple hoses bonded or bundled together in flat, ribbon, or wrapped forms for specific application needs.

How to make Industrial Rubber Hose

Rubber hoses are essential tools used across many industries in daily operations. They are commonly employed to remove water, evacuate waste, or supply machinery with air, water, or raw materials. For example, food producers often use rubber hoses to feed ingredients directly into mixers.

In this factory, they manufacture both low-pressure and medium-pressure rubber hoses. The intended application determines the rubber composition and often the color as well, since industrial hoses are frequently color-coded for quick identification.

The manufacturing process begins when the factory receives raw rubber strips from suppliers. The first step is to run these strips through a mill, where heated rollers soften and smooth the rubber to create an even texture. Next, a machine cuts the rubber into strips with the precise width and thickness needed for the specific hose size.

Workers then lubricate a steel mandrel, which matches the exact bore size of the hose. As the mandrel spins, they wrap the rubber strip around it, layering as needed to achieve the required wall thickness.

Following this, they add one or more reinforcement layers. These are high-strength synthetic fabrics coated with rubber, designed to help the hose withstand internal pressure. The final rubber layer forms the hose’s outer covering. After confirming the final diameter is correct, they wrap the entire assembly tightly with wet nylon tape. This tape will shrink later, compressing all the materials firmly together.

For hoses that require built-in attachments, the process slightly differs. Workers first position the attachment on the mandrel and glue the initial rubber layer to it. They then strengthen the bond with special textile strips and tightly wound carbon steel wire. The wire winding continues down the hose body at a specific angle, engineered to resist vacuum pressure. A soft, stretchy rubber strip is applied to fill gaps between the wires, followed by a layer of high-strength, rubber-coated fabric, and finally, an exterior covering — light blue rubber for this particular model.

These hoses are also tightly wrapped in wet nylon tape and, for increased flexibility, are wrapped with rope to create corrugations. A second layer of nylon tape secures the rope in place.

After the hose construction is complete, the hoses on their mandrels are placed into an autoclave — a cylindrical chamber where hot steam is fed under high pressure. This vulcanization process chemically cures the rubber, giving it its final elasticity and durability.

Once cooled, workers remove the shrunken nylon tape, which has effectively compressed all the layers. The tape is then washed, rewound, and reused.

To release the hose from the mandrel, workers tie one end and gently pump water between the rubber and the mandrel. Thanks to the earlier lubrication, the hose easily separates from the steel form. Workers then trim the ends, cut the hose to the customer’s specified length, coil it, and package it for delivery.

This factory produces a wide range of industrial rubber hoses in various diameters, bore sizes, and flexibility levels. Some hoses also feature specialized designs, such as heat-resistant fabrics embedded within the rubber layers, to meet unique industry needs.

Are You Looking for A Reliable Hydraulic Rubber Hose Manufacturer?

Looking for a reliable rubber hose that's ideal for a range of industrial applications? Look no further than Sinopulse hose factory, one of China's leading manufacturers and suppliers of high-quality rubber products. Our factory produces a wide range of industrial hoses, including rubber hoses that are perfect for use in everything from hydraulic systems to fuel lines and more. Our rubber hoses are made with the highest quality materials and designed for maximum performance and durability. Whether you need a hose that can withstand extreme temperatures, harsh chemicals, or tough conditions, our team of experts can help you find the perfect solution to meet your needs. At Sinopulse, we're committed to providing our customers with the best possible products and service. So why wait? Contact us today to learn more about how our affordable, high-quality rubber hoses can help you take your industrial operations to the next level.

Sinopulse is the leading hydraulic hose manufacturer, with the ability to provide all types of hydraulic rubber hoses. The hydraulic rubber hose is designed to be widely applied for the hydraulic machine, mining machine, heavy-duty machinery, and some other hydraulic system-operated machinery.

Sinopulse is the better option for you, to get your desired custom hydraulic hose, to meet your request. Yes, we can design the unique hydraulic rubber hose for your hydraulic project, and you can tell us your wanted hydraulic hose lengths, diameters, working pressure, burst pressure, and etc.

FAQs

Q: How do I choose the right rubber hose for my application?

A:

The type of rubber hose you choose depends on your application and the specific properties you desire. In general, there are five main factors to consider when choosing a rubber hose:

- Temperature: Depending on the temperature of your application, you will need to select a hose that can withstand extreme hot or cold temperatures.

- Pressure: The pressure rating of the hose will determine how much pressure the hose can withstand before it fails.

- Chemical Compatibility: You need to make sure that the hose you select is compatible with the chemicals it will be exposed to.

- Flexibility: Some hoses are more flexible than others. If your application requires a hose to be routed in a tight space, you will need a more flexible hose.

- Weight: Heavier hoses can be more difficult to handle and may cause fatigue over time. If your application requires a hose to be moved around often, you will need to select a lighter-weight hose.

Q: How to take care of a rubber hose?

A:

In order to prolong the life of your rubber hose, it is important to take care of it. Here are some tips on how to take care of rubber hoses:

- Store the hose in a cool, dry place when not in use.

- Inspect the hose regularly for signs of wear or damage

- When using the hose, avoid sharp bends or kinks.

- Store the hose in a hanging position to prevent kinks.

Q: What are the different types of rubber hoses?

A:

There are many different types of rubber hoses, including those made of different materials, for different applications, and with different levels of flexibility. Some common types include:

- PVC hoses

- Silicone hoses

- EPDM hoses

Q: What factors should be considered when choosing a rubber hose?

A:

Some factors that should be considered when choosing a rubber hose include the type of fluid or gas that will be conveyed through the hose, the operating temperature range of the hose, the maximum operating pressure of the hose, and the minimum and maximum bending radius of the hose. Other factors such as abrasion resistance, chemical resistance, and weather resistance may also be important depending on the application.

Q: What are the most common applications for rubber hoses?

Ans:

Rubber hoses are used in a variety of applications, including automotive, industrial, and plumbing. Automotive applications typically involve fuel lines, coolant lines, and vacuum hoses. Industrial applications often involve air hoses, water hoses, and hydraulic hoses. Plumbing applications may involve garden hoses or other types of hoses used to carry water or other fluids.

rubber hose manufacturer - rubber hose distributors - hose rubber supplier - rubber hose manufacturers - rubber hose suppliers