hydraulic hose

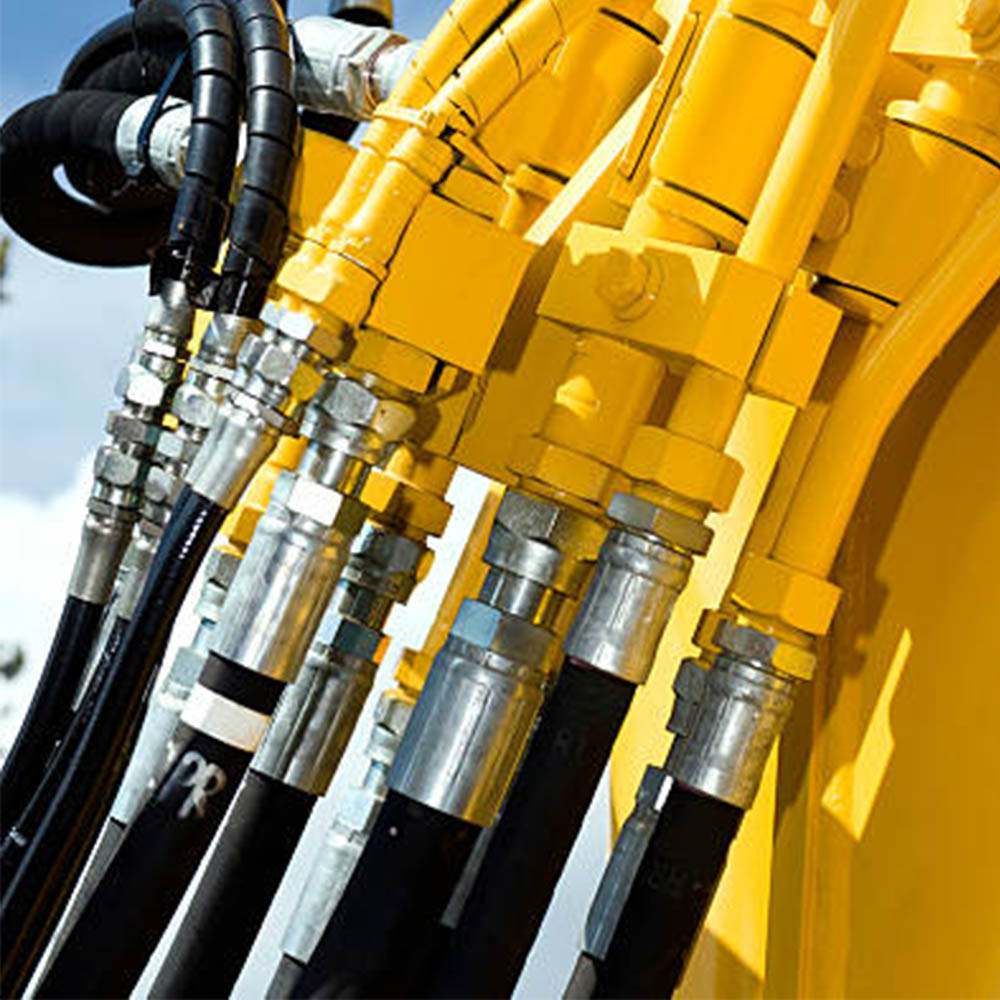

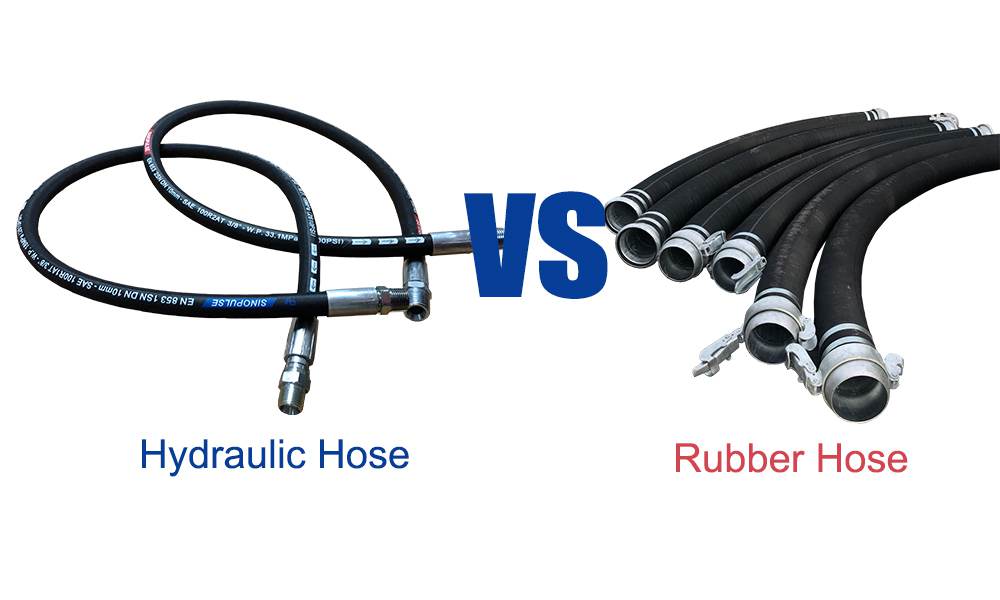

A hydraulic hose is a specialist type of hose that you’ll find in many commercial and industrial settings. Hydraulic hoses are typically constructed from flexible rubber or wire, and feature a series of layers to give the hose its strength and durability. These layers comprise of an inner tube, a reinforced layer and an outer layer.

the purpose of a hydraulic hose is to allow fluid to flow from one component to another – in this case hydraulic fluid. The hose is the conduit that ensures the fluid is able to travel unimpeded and it’s a vital part of keeping hydraulics systems moving. In fact, if a hydraulic hose was to fail it can bring entire production lines to a standstill and take vital machinery offline until the hose can be replaced.

Braided hose:

Designed to power general industrial applications, this is a high-pressure hose that comes in configurations of one, two or three braided steel wires. It’s generally used with petroleum or water-based fluids and operates in temperatures ranging from -40°C to 100°C.

Multi-spiral hose:

This type of hose is very flexible and its internal configuration makes it particularly useful in heavy-construction and high pulse applications. It is normally used to transfer mineral and hydraulic oils or emulsions of water and oil, which makes it particularly useful for constructions and civil engineering, mining and quarrying, oil industries and agriculture – among others.

Low-Pressure Hose:

This kind of hose is textile-braided, which makes it very flexible but not suitable for higher pressures. It’s commonly used in lighter applications such as anti-static delivery, air, lube or return lines.

Stainless Steel Wire-Braided Hose:

These heavy-duty hoses, braided by single or double stainless steel wire, are used in aggressive applications such as the transfer of chemical substances. They are very durable and can withstand extreme temperature and pressure conditions, including in a vacuum.

Thermoplastic Hydraulic Hose:

They’re made of two layers of thermoplastic material separated by a middle reinforcement layer, made of wire or synthetic fibers. The fact that they’re capable of operating at very low temperatures and that they are particularly resistant to abrasion makes them popular in hydraulic-powered lift equipment, as well as lubrication lines where a small outside diameter is needed.