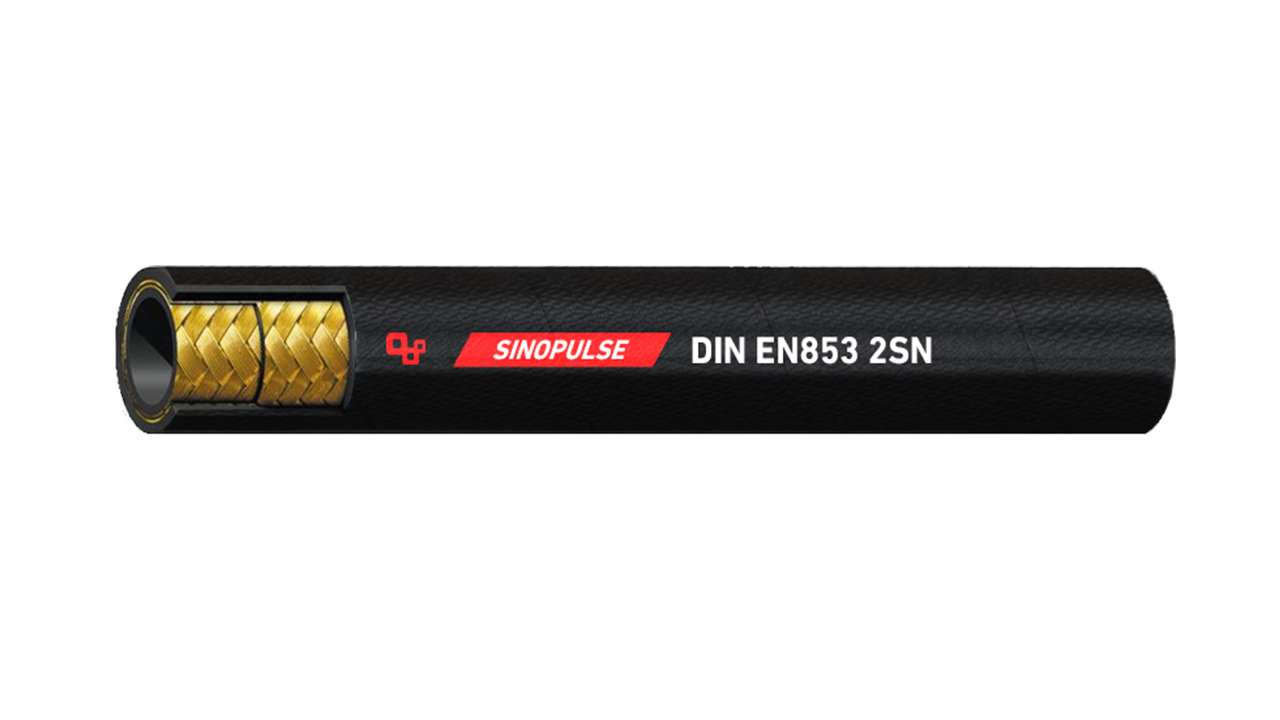

Detailed R2 Hydraulic Hose

R2 Hose Construction:

The R2 hydraulic hose is engineered with a double-wire braid reinforcement, which includes two layers of steel wire woven around the internal tube. This double-braid construction gives improved strength and resilience, making the hose suitable for high-pressure applications. The extra layer of steel wire provides exceptional resistance to pressure and external damage, allowing the R2 hose to manage more demanding functional problems compared to its single-wire equivalents.

Inner Tube: The inner tube is made from rubber or synthetic compounds such as nitrile or synthetic rubber.These materials ensure that the hose maintains its integrity and performance under pressure, have excellent resistance to hydraulic fluids and high pressure.

Reinforcement: The double-wire braid consists of high-tensile steel wires that . The double layer of braid ensures the hose can withstand higher pressures and stresses, minimizing the risk of failure, provide exceptional strength and durability experience for any needs.

Outer Cover: The outer layer is made from robust rubber or synthetic compounds designed to withstand abrasion, weathering, and exposure to chemicals. Materials like neoprene or EPDM are commonly used to protect the hose from external damage and extend its lifespan.

Specifications

Pressure Rating: This high pressure rating makes R2 hoses suitable for more demanding hydraulic systems where high pressure is a regular requirement. R2 hydraulic hoses are designed to handle higher pressures compared to R1 hoses. They typically have a pressure rating ranging from 2,000 to 5,000 psi (pounds per square inch), depending on the hose size and construction.

Flexibility and Bend Radius: Despite its rugged double-wire braid construction, the R2 hose is flexible. The minimum bend radius is typically approximately 5 to 8 times the hose diameter, providing a balance between strength and maneuverability. This flexibility allows it to be installed in tight spaces while maintaining durability under high pressure conditions.

Temperature Range: The R2 hose typically operates effectively over a temperature range of -40°C to +100°C (-40°F to +212°F). This temperature range ensures that the hose remains flexible and functional in a wide range of operating environments. In some cases, specialized R2 hoses are available for a wider temperature range, depending on the materials used.

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m | Codigo | Codigo |

| SNP-2SN03 | 2SN-03 | 4.8 | 3/16" | 4.6-5.4 | 14.1 MAX . | 415 | 6018 | 1660 | 24070 | 90 | 0.340 | 50/100 | ××××1-××-03 | 00210-03 |

| SNP-2SN04 | 2SN-04 | 6.4 | 1/4" | 6.2-7.0 | 15.7 MAX . | 400 | 5800 | 1600 | 23200 | 100 | 0.372 | 50/100 | ××××1-××-04 | 00210-04 |

| SNP-2SN05 | 2SN-05 | 7.9 | 5/16" | 7.7-8.5 | 17.3 MAX . | 350 | 5075 | 1400 | 20300 | 115 | 0.430 | 50/100 | ××××1-××-05 | 00210-05 |

| SNP-2SN06 | 2SN-06 | 9.5 | 3/8" | 9.3-10.1 | 19.7 MAX . | 330 | 4785 | 1320 | 19140 | 125 | 0.560 | 50/100 | ××××1-××-06 | 00210-06 |

| SNP-2SN08 | 2SN-08 | 12.7 | 1/2" | 12.3-13.5 | 23.0 MAX . | 275 | 3988 | 1100 | 15950 | 180 | 0.640 | 50/100 | ××××1-××-08 | 00210-08 |

| SNP-2SN10 | 2SN-10 | 15.9 | 5/8" | 15.5-16.7 | 26.2 MAX . | 250 | 3625 | 1000 | 14500 | 205 | 0.732 | 50/100 | ××××1-××-10 | 00210-10 |

| SNP-2SN12 | 2SN-12 | 19.1 | 3/4" | 18.6-19.8 | 30.1 MAX . | 215 | 3118 | 860 | 12470 | 240 | 0.930 | 50/100 | ××××1-××-12 | 00210-12 |

| SNP-2SN16 | 2SN-16 | 25.4 | 1" | 25.0-26.4 | 38.9 MAX . | 165 | 2393 | 660 | 9570 | 300 | 1.360 | 50/100 | ××××1-××-16 | 00210-16 |

| SNP-2SN20 | 2SN-20 | 31.8 | 1.1/4" | 31.4-33.0 | 49.5 MAX . | 125 | 1813 | 500 | 7250 | 420 | 1.850 | 20/40 | ××××1-××-20 | 00210-20 |

| SNP-2SN24 | 2SN-24 | 38.1 | 1.1/2" | 37.7-39.3 | 55.9 MAX . | 90 | 1305 | 360 | 5220 | 500 | 2.300 | 20/40 | ××××1-××-24 | 00210-24 |

| SNP-2SN32 | 2SN-32 | 50.8 | 2" | 50.4-52.0 | 68.6 MAX . | 80 | 1160 | 320 | 4640 | 630 | 2.650 | 20/40 | ××××1-××-32 | 00210-32 |

Pros of Using R2 Hoses:

High Pressure Resistance: Capable of handling significantly higher pressures compared to R1 hoses, making them suitable for more demanding applications.

Enhanced Durability: The double-wire braid provides superior strength and resistance to external damage, extending the hose’s lifespan.

Flexibility: Maintains good flexibility while offering high-pressure performance, allowing for easier installation in various configurations.

Safety: Reduced risk of hose failure under high-pressure conditions, which enhances operational safety and reliability.

Cost: Generally more expensive than R1 hoses due to the additional reinforcement and construction complexity.

Bend Radius: While flexible, the minimum bend radius is larger compared to R1 hoses, which may limit installation in very tight spaces.

Weight: The additional layer of steel braid adds to the weight of the hose, which may be a consideration in applications where hose weight is a factor.

Temperature Sensitivity: While the standard temperature range is broad, extreme temperatures may still affect performance, particularly if the hose is exposed to conditions outside its specified range.

Applications

Typical Use Cases and Industries: R2 hydraulic hoses are widely used in industries where high-pressure hydraulic systems are common. Typical applications include:

Construction: Essential in hydraulic machinery like excavators, bulldozers, and cranes, where high-pressure operations are standard.

Mining: Used in mining equipment such as drills and loaders that operate under high pressure.

Oil and Gas: Applied in hydraulic systems for drilling rigs and other equipment requiring high-pressure hoses.

Manufacturing: Utilized in hydraulic presses and heavy machinery that demand higher pressure capabilities.

When to Choose R2

High-Pressure Applications: R2 hoses are designed to handle higher pressures, typically up to 5000 psi. They are essential in hydraulic systems where high pressure is a regular requirement, such as in heavy machinery, construction equipment, and high-pressure industrial processes.

Durability Requirements: When the application demands superior durability and strength, the double-wire braid reinforcement of the R2 hose provides enhanced resistance to pressure and external damage. This makes R2 hoses suitable for environments where hoses are subject to heavy wear and tear.

High-Stress Environments: For operations in harsh conditions or where the hydraulic system experiences high stresses, R2 hoses offer better performance and safety due to their robust construction and higher pressure rating.

FAQ

what is R2 hydraulic hose

SAE 100 R2 steel wire reinforced hydraulic hose is suitable for conveying petroleum-based hydraulic oil due to its oil-resistant tube. In addition, it can convey oil products without generating excessive heat and leakage. It is mainly used in some mobile equipment such as agricultural tractors, dump trucks and in-plant hydraulic equipment. It consists of three parts: tube, reinforcement layer and outer layer. The tube is made of oil-resistant synthetic rubber, so it is mainly used for conveying oil products. The reinforcement layer is made of two layers of high-strength braided steel wire, which makes the hose structure strong and resistant to high pressure. Therefore, it has excellent performance in high-pressure working environments. The outer layer is made of high-quality synthetic rubber, which is resistant to weather, ozone, corrosion, abrasion, aging, sunlight and cutting. The hose has a longer service life as a result.

what is SAE 100R2AT Hydraulic Hose

SAE 100R2AT Hydraulic Hose is recommended for hydraulic system service with petroleum and water-base fluids, or general industrial service. Long-lasting cover is suitable for many mobile hydraulic applications. R2 Hydraulic hose contains 2 layers of high tensile wire braids

what is SAE 100 R2AT / DIN EN 853 2SN braid high pressure hydraulic hose

SAE 100 R2AT / DIN EN 853 2SN braid high pressure hydraulic hose is often found in mobile equipment including farm tractor, dump truck and in-plant hydraulic equipment. SAE 100R2AT hydraulic hose has three parts - excellent oil resistance Nitrile tube, good weather and petroleum products resistance Neoprene cover and double high-tensile wire braid reinforcement. It is ideal for outdoor working environments including offshore, forestry, construction and mining where high abrasion resistance is required. Petroleum- and water based hydraulic fluids with high pressure can pass through the inner tube smoothly and freely without producing excessive heat and leak.

What is R2 in hose?

In the context of hoses, "R2" typically refers to a type of hydraulic hose known as "SAE 100R2." This hose is designed with two layers of high-tensile steel wire braids for reinforcement and is commonly used for high-pressure hydraulic applications. It meets the standards set by the Society of Automotive Engineers (SAE) for performance and durability.

What is the pressure rating of an R2 hydraulic hose?

R2 hoses typically have a pressure rating up to 5000 psi, depending on the hose size and construction, making them suitable for high-pressure hydraulic systems.

What are the differences between types of R Hose?

There are a few different type of R hose, including R1, R2, R3, R12, R13, R15, R16, & R17. While these hoses are generally made of the same types of materials, the ratios of materials changes from hose to hose. Because of these differing ratios, each hose is rated for different pressures and applications.

What is the main difference between R1 vs R2 hydraulic hoses?

R1 hoses have a single-wire braid reinforcement and are suited for medium-pressure applications, while R2 hoses feature a double-wire braid for higher pressure and increased durability.