What is a hose?

1.the hose is mainly used as wire and cable protection hose, civil shower hose, the inner diameter from 3mm to 150mm, the inner diameter of 3mm-25mm small diameter hose is mainly used for precision optical line protection.

2. according to the use of the hose is mainly divided into: threading hose, drainage hose, ventilation hose, shower hose and wire harness tube; according to the material is mainly divided into: hydraulic hose, stainless steel hose, corrugated hose, plastic hose and rubber hose. There are many kinds of high-pressure water cleaning fittings, the selection of the appropriate fittings should be used, casing design should be standardised and reasonable. Sharp grooves and irregular sizes will break the steel wire reinforcement layer. Clamping joints, should be based on the internal and external diameter of the hose to determine the amount of clamping.

3. the hose is light weight, corrosion resistance, high temperature resistance, good expansion and contraction, bending resistance, good tensile performance, strong resistance to side pressure, easy to thread installation, in the industrial and civil fields are widely used.

What is a Hydraulic Hose?

hydraulic hose is one of important type of hoses. It is a crucial component in hydraulic systems, playing a vital role in transmitting fluid power within machinery and equipment. It is designed to withstand high pressure and carry hydraulic fluids between different components, such as pumps, valves, cylinders, and motors.

Types Of Hydraulic Hoses

Type 1: Standard Hydraulic Hoses

The first type of hydraulic hose is the standard hydraulic hose. These hoses are made of synthetic rubber and reinforced with steel wire. They are suitable for hydraulic systems with a maximum pressure of 3000 psi. Standard hydraulic hoses are used in applications such as construction equipment, mining and industrial machinery.

Type 2: Steel Wire Braided Hydraulic Hose

Steel wire braided hydraulic hoses are made of synthetic rubber and reinforced with a single or double steel wire braid. They are suitable for hydraulic systems up to 6000 psi. Steel wire braided hydraulic hoses are used in applications such as agriculture, construction equipment, and mining.

1-Wire: Not as common as 2-wire hose, used in low-pressure hydraulic systems.

2-wire: most common braided hose, used in medium-pressure hydraulic systems

Tensile Braided (1- or 2-wire): for low-pressure hydraulic systems

Braided hoses are more flexible than spiral hoses and are ideally suited for in-equipment wiring. They are typically used in smaller sizes for medium and high pressure applications and larger sizes for medium and low pressure applications. Braided hydraulic hose is manufactured to SAE standards (100R1, 100R2, 100R16, 100R17, or 100R19) or ISO 18752. ISO specifications also include letter codes for pulse life ratings.

Up to 5800 PSI

1/4 inch -1 inch ID

Type 3: Spiral hydraulic hose

Spiral hydraulic hoses are made of synthetic rubber and reinforced with a spiral steel wire. They are suitable for hydraulic systems up to 8000 psi. Spiral hydraulic hoses are used in applications such as oil and gas drilling, mining, and heavy equipment.

4-Wire: Typically used for heavy equipment requiring very high pressures (4,000-6,000 PSI), good for impulse control

6-Wire: Typically used for heavy equipment and high-pressure applications (up to 6,000 PSI) requiring larger diameter hose.

Spiral hoses offer higher working pressures across the entire size range. Although they are heavier in construction than braided hoses, they typically have higher pulse life, making them ideal for more demanding applications. Spiral hoses are manufactured to SAE standards (100R12, 100R13, and 100R15) or ISO 18752. ISO specifications also include letter codes for pulse life ratings. Most manufacturers go beyond these specifications and offer a line of ‘Constant Pressure’ hose, meaning the entire size range is capable of 3000, 4000, 5000 or 6000 PSI.

Up to 6000 PSI

3/8 inch -2 inch ID

Type 4: Thermoplastic Hydraulic Hose

Thermoplastic hydraulic hoses are made of thermoplastic materials and reinforced with single or double-ply synthetic fibres. They are suitable for hydraulic systems up to 10,000 psi. Thermoplastic hydraulic hoses are used in applications such as medium and high pressure hydraulic lines, mobile equipment and agricultural machinery.

The construction is typically made of nylon tubing, synthetic fibre reinforcement and a polyurethane cover. Thermoplastic hose is commonly used in general hydraulics, material handling, forklift and near-electrical systems. It can withstand similar pressures to 1- and 2-wire hoses, but can be installed in applications where rubber hoses with steel wire reinforcement would not work. The polyurethane cover performs very well under the wear and tear of forklift pulleys. Non-conductive thermoplastic hoses are perfect where power is an issue, such as in bucket lifts for repairing electrical wires.

Type 5: Teflon or PTFE hose

It consists of a Teflon tube reinforced with a stainless steel braid, without the need for an outer layer, as the stainless steel braid does not corrode under normal conditions. Teflon hose is used in applications where corrosion resistance, chemical compatibility, or high temperatures are required. It is rated to 450°F.

Some things to keep in mind when purchasing Teflon hose include size and bend radius. Sizes are typically 1/16 in. smaller than those shown in the part number. For example, -04 hose is 3/16 inch and -06 hose is 5/16 inch. Therefore, just because your part number ends in 04 does not mean the hose is ¼ inch. This applies to all sizes. Regarding the bend radius, remember that Teflon hose is a hard plastic tube covered with braid. If you bend a hard plastic hose to the point of kinking, you are damaging the hose and creating a weak point. Be careful when wiring in tight spaces.

Type 6: return hydraulic hose

A return hose is a hydraulic hose that handles suction and returns hydraulic fluid to the beginning of the system. This hose is usually a rubber hose with a textile braid cover to provide positive pressure and a helix for suction.

Type 7: Truck Hose - Hydraulic Hose

Truck hose is a special category within the hydraulic hose family.SAE 100R5 defines it as a textile-covered, single-wire hose used in many systems on road vehicles. Like Teflon hose, truck hose sizes do not follow the standard 1/16 method used for standard hydraulic hose. Actual hose ID sizes range from 1/16 inch to ⅛ inch, depending on the size.

Up to 300 PSI

Inside diameter 1/4 inch -2 inch

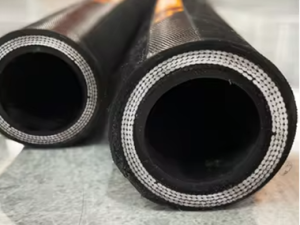

Structure of hydraulic hose

The structure of a hydraulic hose usually consists of three parts: an inner rubber layer, a reinforcing layer and an outer rubber layer. Each layer plays a vital role in the performance of a hydraulic hose.

Inner rubber tube layer

The inner rubber layer is the core part of the hydraulic hose, mainly used for transporting hydraulic oil or other fluids. It needs to have good oil resistance, corrosion resistance and high temperature resistance to prevent the liquid medium from corroding the steel wire reinforcement inside the hose. The inner rubber layer is usually made of specialised rubber material to ensure fluid tightness and anti-leakage function.

Reinforcement layer

The reinforcement layer is the backbone of the hydraulic hose and is responsible for withstanding the high pressures in the hydraulic system. It is usually made of steel wire, polyester fibre or other high-strength materials that are braided or twisted. The main function of the reinforcement layer is to provide sufficient strength and elasticity to ensure that the hose remains stable under high-pressure and high-stress environments. According to the design of the reinforcement layer, it can be divided into steel wire braid structure and steel wire winding structure, and the difference between the two lies in the pressure-bearing capacity and the applicable pressure range. There are three types of reinforcing layers: braided, spiral and helix (typically used for suction/vacuum).

outer rubber cover

The outer rubber layerThe outer rubber layer serves to protect the hose from damage caused by the external environment, such as abrasion, UV radiation, chemicals or mechanical impact. It is usually made of abrasion-resistant, UV-resistant and heat-resistant rubber material. The outer rubber layer not only extends the service life of the hose, but also ensures the stability of the hose in harsh environments.

hydraulic hoses classified according to pressure levels

Hydraulic hoses can be categorised according to the pressure at which they are designed to operate under normal operating conditions: low, medium and high pressure. Hoses can also be categorised based on construction/reinforcement type, temperature range and other performance characteristics.

Low pressure: less than 250 PSI, most commonly with textile/fabric braid reinforcement

Medium Pressure: up to 3,000 PSI, most often with steel wire braid reinforcement

High Pressure: 3,000-6,000 PSI, using a mix of wire braid and spiral braid reinforcement

Factors to consider when choosing a hydraulic hose type

There are several factors to consider when choosing a hydraulic hose type. These factors include system pressure, fluid temperature, hose length, bend radius and abrasion resistance.

System pressure is the maximum pressure that a hydraulic system can withstand. The pressure rating of the type of hydraulic hose used must be equal to or higher than the system pressure.

Fluid temperature is the temperature of the hydraulic fluid flowing through the hose. The type of hydraulic hose used must be able to withstand the fluid temperature.

Hose length is the distance between the hydraulic components to which the hose is connected. The type of hydraulic hose used must be long enough to reach between the components.

Bend radius is the smallest radius at which a hydraulic hose can be bent without kinking or damage. The bend radius of the type of hydraulic hose used must be appropriate for the application.

Abrasion resistance is the ability of a hydraulic hose to withstand abrasion caused by external factors such as friction and impact. If the application involves exposure to such elements, the hydraulic hose used must have high abrasion resistance.

Conclusion

Hydraulic hose is a key component of a hydraulic system. There are 7 main types of hydraulic hoses: standard hydraulic hoses, steel wire braided hydraulic hoses, spiral hydraulic hoses, thermoplastic hydraulic hoses, Teflon or PTFE hose, return hydraulic hose and truck hoses. When selecting the type of hydraulic hose to use, factors such as system pressure, fluid temperature, hose length, bend radius and abrasion resistance need to be considered to ensure that the hydraulic system works efficiently and effectively.

Sinopulese is a professional hydraulic hose manufacture and supplier, provides high quality hydraulic hose, industrial hose and fittings for various industries. We have over 20 years of experience in hose manufacturing.

Not sure what type of hydraulic hose you need? Our team can not only provide the right hydraulic hose, but also the expertise and oversight needed to install and operate it in your system. We can produce any type of hydraulic hose for you, so please feel free to enquire!