What's a Hydraulic Hose Layline?

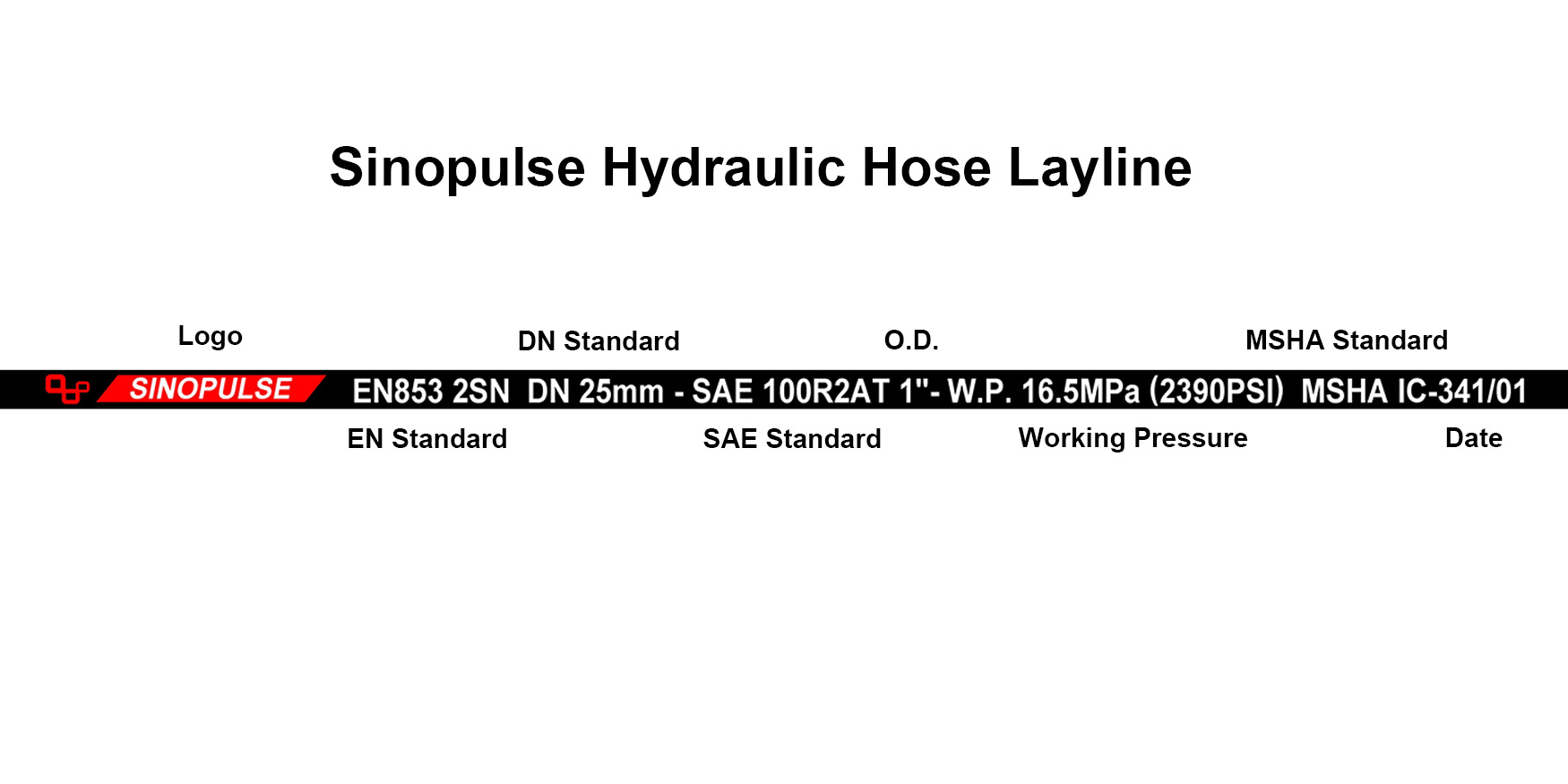

A hydraulic hose layline is the published or embossed line of details running along the outer cover of a hydraulic hose. It's not just an aesthetic stripe-- it serves as a referral guide for individuals and service technicians. Here's what it typically consists of and why it is very important.

Read A Hydraulic Hose Layline

Manufacturer Name or Brand: Identifies the hose's maker.

Hose Type or Series: For example, SAE 100R2AT, EN 857 2SC, etc.

Size: Usually shown in dash size (e.g., -06 for 3/8") or in inches/mm.

Pressure Rating: Maximum working pressure, often in PSI or bar.

Temperature Range: Operating range of the hose material.

Construction: Type of reinforcement (e.g., wire braid, spiral).

Standards Compliance: SAE, EN, ISO, or other relevant certifications.

Date Code or Batch Number: Useful for traceability and quality control.

Flow Direction Arrow (optional):On hoses where direction matters.

Hydraulic Fitting Size Chart

1. Dash Size:

The dash size is likewise the technique to measure the hydraulic hose size, and the dash size can be converted to inches. Right here is the hydraulic hose dash size conversion table, you can calculate the dash size to inches. Simply put, the dash size equates to an I.D. of a hydraulic hose in 1/16 ″ increments. For example, a -06 hose would certainly show a hose with an I.D. of 6/16 ″-- or 3/8 ″.

2. Inner Diameter:

Inner Diameter (I.D.) refers to the internal width of a hose’s circular cross-section and plays a critical role in determining fluid flow velocity. Selecting a hose with too large an Inner Diameter may lead to reduced system efficiency, while choosing one that’s too small can result in excessive pressure drops, potential leaks, and even damage to the system. Therefore, it’s essential to choose the accurate Inner Diameter—typically measured with precision to one decimal place—to ensure optimal performance and safety.

3. Inch and mm Calculation:

Inch and mm are both units of length commonly used to measure the size or length of a hydraulic hose. To ensure precise specifications, you can calculate the conversion between these units. For reference, 1 inch is equal to 25.4 millimeters. A unit converter can help simplify this process when switching between inches and millimeters during measurements.

4. Hydraulic Hose Working Pressure

Working pressure refers to the range of pressure a hydraulic hose is designed to withstand under normal operating conditions. It indicates the safe pressure limit during regular use and helps ensure the hydraulic hose performs reliably within its specified working pressure range.

Selecting Proper Hydraulic Hose for Your Application

Determine Operating Pressure:

Determine the maximum and minimum pressure levels required by your hydraulic system, taking into account both the continuous working pressure and any potential pressure spikes or surges. This helps ensure the selected hose can handle the full range of operating conditions safely and reliably.

Calculate Flow Rate:

Determine the necessary flow rate, usually expressed in gallons per minute (GPM) or liters per minute (LPM). This information is essential for choosing a hose with the correct inner diameter to ensure smooth fluid flow while minimizing pressure loss and turbulence.

Assess Fluid Compatibility:

Verify the type of hydraulic fluid used in your system, as hoses must be compatible with different fluid types such as oil-based, water-based, or synthetic fluids. Using an incompatible hose can lead to material degradation and increase the risk of leaks, so selecting the right hose for the fluid is essential.

Evaluate Temperature Range:

Identify the temperature range in which the hydraulic system will operate, including both the surrounding environment and the hydraulic fluid temperature. Choose hoses that are rated to function effectively within this range to ensure consistent performance and maintain their structural integrity over time.

Consider Environmental Factors:

Assess the external environment for factors like UV exposure, chemical contact, abrasion, and mechanical stress. Select hoses equipped with suitable outer coverings and reinforcements to ensure durability and protection under these conditions.

Identify Flexibility Requirements:

Evaluate the necessary flexibility and bend radius for the hose, especially in applications with frequent movement or tight installation spaces. In such cases, using hoses with greater flexibility and a smaller bend radius helps prevent kinking and potential damage.

Select the Appropriate Inner Diameter (I.D.):

Determine the correct hose Inner Diameter (I.D.) based on the calculated flow rate to ensure it can carry the required volume without introducing excessive pressure drop or turbulence in the system.

Choose the Correct Outer Diameter (O.D.):

Select a hose with an Outer Diameter that fits the installation space and accommodates the necessary fittings and clamps for secure and stable connections.

Verify Pressure Rating:

Ensure the hose’s Pressure Rating exceeds the system’s working pressure, including potential pressure spikes, to maintain safe and efficient operation.

Check Temperature Rating:

Verify that the hose is rated for the system's temperature range to ensure reliable performance under all operating conditions.

Confirm Fluid Compatibility:

Make sure the hose material is fully compatible with the system's hydraulic fluid to prevent chemical degradation and ensure long-term performance (Fluid Compatibility).

Assess Durability and Longevity:

Choose hoses with suitable reinforcement layers and protective outer covers to enhance durability and extend service life in demanding operating environments.

FAQ

Q1: What is a Hose Layline?

A: The layline is the printed text along the length of a hose that provides key information such as the Inner Diameter (I.D.), pressure rating, hose type, manufacturing date, and standards compliance. It helps with correct hose identification and replacement.

Q2: How to tell if a hose is 3/4 or 5/8?

A: Measure the Inner Diameter (I.D.) of the hose using a caliper or ruler.

-

A 5/8 inch hose has an I.D. of approximately 15.9 mm,

-

A 3/4 inch hose has an I.D. of approximately 19.1 mm.

Accurate measurement is essential to ensure proper fittings and clamps.

Q3: What does a dash 12 (-12) refer to on a hydraulic hose?

A: The dash size is a standard method to indicate the Inner Diameter (I.D.) of a hose in sixteenths of an inch.

-

A -12 (dash 12) hose has an I.D. of 12/16", or 3/4 inch.

It’s a quick way to reference hose sizes when selecting or replacing hydraulic hoses.

Q4: How to tell if a hydraulic hose is 2-wire or 4-wire?

A: Look at the hose layline for specifications such as SAE or EN standards, which usually indicate the construction.

Alternatively, you can:

-

Check manufacturer documentation,

-

Inspect the cross-section (if cut),

-

Or feel the hose: 4-wire hoses are generally stiffer and thicker than 2-wire hoses due to the additional reinforcement.

The number of wires directly affects the Pressure Rating and working pressure.

Q5: What size is a #4 hydraulic hose?

A: A #4 hydraulic hose (dash 4 or -4) has an Inner Diameter (I.D.) of 4/16", or 1/4 inch.

This size is commonly used in low to medium pressure systems for compact hydraulic circuits.