This is a Professional Guide for Hose Repair and Replacement Solutions

In the world of hydraulic systems, downtime is costly—and reliability is non-negotiable. When a hydraulic hose becomes damaged or requires modification, many professionals ask the question: Can you splice a hydraulic hose, or should you replace it entirely?

In this guide, we’ll explore the feasibility of splicing hydraulic hoses, the available methods, the critical considerations involved—and most importantly, how using the right hose and fittings can directly impact your operational efficiency, safety, and cost.

At Sinopulse, we manufacture a full range of high-quality hydraulic hoses and fittings designed specifically to support crimping and field repair applications. Whether you're a brand owner or a bulk buyer seeking reliable hose assemblies, our products are engineered to enhance your productivity and lower your maintenance costs.

Understanding the Basics: Is Splicing a Hydraulic Hose Possible?

Yes, splicing a hydraulic hose is technically possible, but it comes with important limitations and requirements. While a professional splice can serve as a temporary or even semi-permanent solution, it must be done using proper tools, compatible materials, and correct techniques to ensure the connection remains secure under pressure.

In most high-pressure applications, replacing the damaged hose section with a properly crimped new assembly is the safest and most reliable option. However, in field conditions or urgent repairs, splicing may be a practical solution—if executed correctly.

Key Factors to Consider Before Splicing a Hydraulic Hose

1. Material Compatibility

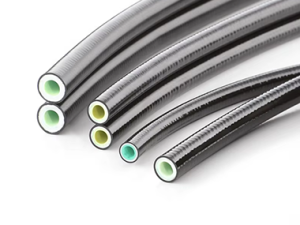

Hydraulic hoses are manufactured from materials such as synthetic rubber, thermoplastics, or PTFE (Teflon). Each material responds differently to heat, pressure, and chemical exposure.

Always ensure that the splice components—fittings, sleeves, and clamps—are compatible with the hose’s inner and outer construction. Using mismatched materials may lead to leaks or hose degradation.

Sinopulse Advantage:

We provide a complete range of hoses compatible with multiple splice and crimping systems. Whether your system uses steel wire braid, spiral reinforcement, or thermoplastic materials, we supply the right match.

2. Hose Size and Pressure Rating

Hydraulic systems often operate at extremely high pressures. A splice must maintain the original hose diameter and pressure rating to ensure operational safety.

Any deviation can result in pressure loss, system inefficiency, or dangerous failure under load.

At Sinopulse, all our hydraulic hoses are rigorously pressure-tested and meet or exceed international standards (SAE, DIN, ISO), ensuring they’re ready for use in demanding splice or replacement scenarios.

3. Location of the Damage

Splicing is most feasible when the damage is located in a straight, accessible portion of the hose—not near fittings, sharp bends, or high-vibration points.

Proper alignment is critical for a secure seal and safe pressure containment.

Methods for Splicing a Hydraulic Hose

1. Crimping Method (Recommended)

Crimping is the most reliable and professionally accepted splicing technique. It involves using a hydraulic crimping machine to attach fittings or connectors securely to the hose ends.

Benefits:

-

Leak-free, high-pressure tolerance

-

Long-term durability

-

Strong resistance to vibration and pressure fluctuations

Sinopulse supplies premium crimp fittings and hoses designed for compatibility across all major crimping machines. Our products ensure fast, consistent results for your in-house or mobile repair operations.

2. Field-Attachable Reusable Fittings

These are reusable fittings that can be installed without a crimping machine. They are particularly useful for field repairs or emergency situations.

Limitations:

-

Not recommended for high-pressure or mission-critical systems

-

May be used as a temporary solution until full replacement

We offer a full line of reusable field-attachable fittings—ideal for fleet maintenance, agricultural equipment, or remote job sites.

3. Splice Kits

Splice kits may include sleeves, clamps, and lubricants designed for specific hose types. While convenient, they require strict adherence to the manufacturer’s instructions.

Improper installation can cause fitting slippage or hose rupture under load.

Sinopulse can customize hose repair kits tailored to your specific hose type, diameter, and system requirements.

Step-by-Step: How to Splice a Hydraulic Hose (For Professionals Only)

Disclaimer: Splicing should only be performed by trained personnel using compatible components and calibrated tools.

Materials Needed:

-

Hydraulic hose splice kit or compatible fittings

-

Crimping machine tool or wrench (depending on method)

-

Hose cutter or sharp blade

-

Lubricant (if required)

-

Safety gloves and goggles

Procedure:

-

Safety First

-

Shut down and fully depressurize the hydraulic system.

-

Drain any fluid from the hose.

-

-

Cut and Clean

-

Make a clean, square cut on both damaged ends.

-

Remove debris and inspect for inner tube damage.

-

-

Assemble the Splice

-

Slide the sleeve or fitting onto the hose ends.

-

Apply lubricant if needed to ease insertion.

-

Ensure alignment is straight.

-

-

Crimp or Tighten

-

Follow the equipment manufacturer’s instructions for crimping.

-

Confirm crimp dimensions and inspect for visible gaps.

-

-

Pressure Test

-

Gradually re-pressurize the system and inspect for leaks.

-

Monitor under load for at least one full cycle.

-

When Should You Splice vs. Replace?

| Situation | Recommended Action |

|---|---|

| Critical system hose | Full replacement |

| Minor surface damage | Temporary splice possible |

| Emergency field repair | Reusable fittings or kits |

| Cost-saving in low-risk area | Professionally crimped splice |

| Frequent failure at same point | Upgrade to higher-quality hose or fitting |

Important: A new, properly crimped hose from a trusted supplier like Sinopulse offers superior safety, longer life, and greater peace of mind.

Why Choose Sinopulse for Your Hydraulic Hose and Fitting Needs?

As a leading manufacturer focused on supporting bulk buyers, OEMs, and brand owners, Sinopulse offers:

- A full range of hydraulic hoses and fittings suitable for high-pressure, high-flexibility applications

- Precision-manufactured fittings for all major crimping systems

- Custom solutions including hose assemblies, field repair kits, and branded packaging

- Reliable, cost-effective products that reduce downtime and increase operational efficiency

- Strict quality control and compliance with international standards (SAE, DIN, ISO)

Our goal is to be your long-term partner in hydraulic system efficiency—whether you're building equipment, maintaining a fleet, or supplying your own market with branded assemblies.

Frequently Asked Questions (FAQs)

1. Can you splice a hydraulic hose under pressure?

No. The system must be fully depressurized before any splice or repair is attempted.

2. Is it safe to splice a damaged hose?

Only if the damage is minor, the splice is done professionally, and the application is non-critical.

3. Are spliced hoses as strong as new ones?

Splices may offer a temporary fix, but a professionally crimped new hose always offers better integrity.

4. Should I try to splice a hose myself?

Only if you are trained and using compatible tools and materials. When in doubt, consult a professional—or contact Sinopulse for support.

Conclusion

Splicing a hydraulic hose can be a useful solution in certain situations, but it requires careful consideration of hose material, pressure rating, location, and application. When executed correctly with the right tools and components, a splice can offer short-term relief—but for long-term reliability, replacing the hose with a properly crimped assembly remains the best practice.

At Sinopulse, we are committed to providing the high-quality hoses and fittings that support your crimping operations, improve efficiency, and lower overall costs. Whether you're building new systems or maintaining existing equipment, our products are engineered to keep your business moving—safely and reliably.

Need support with your hydraulic hose needs?

Contact our team for product specifications, OEM solutions, or bulk order assistance.