Efficiency is important for every stage of a process and every aspect of a business, especially when your business relies on hydraulic systems. The efficiency of a hydraulic system depends on every component of the system, including hydraulic hoses. Choosing a good hydraulic hose can not only save business time, energy, resources, but also save money.

There are many differences in hydraulic hoses, from pressure range to abrasion resistance to temperature grade. The best hydraulic hose for you is one that improves performance and efficiency for your application, but understanding which hose is best for your application is not always that easy. Let's take a look at different types of hoses and their respective advantages.

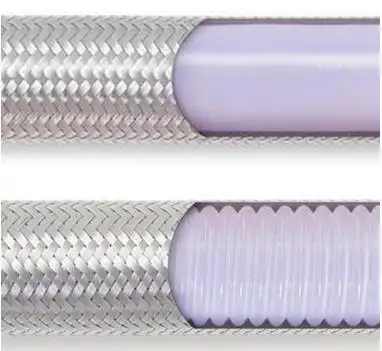

Braided hydraulic hoses are typically the best for high-performance applications like power steering and hydraulics. Braided hoses consist of one or two wires. Compared to a two-wire braided hose, a single-wire hose has a slightly smaller working temperature range, but the diameter range is about the same, and it depends on the grade. As far as SAE standards are concerned, PDI's single-wire hydraulic hoses comply with SAE 100R1 standards, while two-wire hydraulic hoses comply with SAE 100R2 standards.

Spiral hydraulic hoses are versatile and are the best hoses for various applications from mining, forestry, off-road to high performance. They come in 4-wire and 6-wire. Typically, these hoses transport oil-based and water-based fluids. Spiral hydraulic hoses have a broad working temperature and pressure, they are rugged, durable and suitable for a wide range of uses.

Stainless Steel PTFE Hoses (also named stainless steel Teflon® hoses) are more popular than other hydraulic hoses primarily because their flexibility is double that of standard 100R14 hoses. Therefore, they are the best hoses for chemical transfer, food and beverage applications, steam, compressor discharge, automotive and air brake applications. PDI's stainless steel Teflon® hoses meet the requirements of SAE 100R14.

When weight becomes the main metric for your business, thermoplastic hoses come into play. So they are the best hoses for applications like forklifts, construction, and automotive. PDI's thermoplastic hydraulic hoses meet SAE 100R7, 100R8, 100R18, and J517 standards, are reliable and versatile, long in length, and able to transport high-pressure fluids. In the return side of hydraulic systems, the suction line ensures that fluids are safely and correctly transported from -40 to 302°F. PDI's return lines comply with SAE 100R4 standards.

For extremely high temperature applications, flexible metal hoses or corrugated metal hydraulic hoses may be the hose of choice. Corrugated flexible metal hydraulic hoses are suitable for conveying steam and hot fluids up to 2,000°F. If you need to connect misaligned pipes, flexible metal hoses can serve as connectors. Typical sizes are up to 2".

In racing applications, high-performance hydraulic hoses are the best choice for conveying hydraulic oil as well as fuels, coolants, air, and N2O. Because these hoses are designed for racing, they are lightweight and can withstand pressures up to 2,500 psi.

Not all hydraulic hoses are the same; there are many different types of hoses on the market. Make sure to choose a suitable hydraulic hose according to what your field needs or consult Sinopulse experts to ensure that you have the best hydraulic hose for the job to maximize operating efficiency.

How Sinopulse ensures you get the best hoses Sinopulse not only manufactures hydraulic hoses and fittings, but also industrial hoses, PVC hoses, pneumatic hoses, automotive hoses, silicone hoses, industrial vacuum hoses, hydraulic hose protection sleeves and more. All products comply with ISO, SAE, and MSHA standards and specifications. The company has more than 20 production lines for hydraulic and industrial hoses, including advanced high-speed weaving machines and high-speed winding machines imported from Europe, Italian automatic winding machines, etc., with a daily production capacity of 15,000 meters. Sinopulse can also offer customized hose products to meet your local market and standards. Please send us your inquiry right away.

Standard Control The structure and performance of hydraulic hoses are governed by a variety of national and international standards, including ISO, BSI, SAE, DIN, API, and CETOP. Most proprietary hoses comply with one standard or another, with SAE standards most widely followed in the United States. The SAE standards provide common specification, size, and performance for the most commonly used hoses in mobile and stationary hydraulic systems. Specific standard products are here, if you can't find the standard products you need you can contact us, as a professional hydraulic hose manufacturer, we can produce the best hydraulic hose that meets your standards for your needs

Factory Quality Test Control Raw materials: Rubber sheet hardness test viscosity test and vulcanization test, steel wire tensile test Finished hose testing: working pressure test, leak point test, burst pressure test, pulse test

Professional Product Advice and After-sales You can contact our hydraulic hose experts with nearly 30 years of production experience for how to choose the appropriate hydraulic fittings, what are the standards for hydraulic hoses, and if you have any questions after purchasing, you can also contact us at any time, we have 24h service, to help you solve any problems related to hydraulic hoses!