Hydraulic hose fittings are used to securely connect hydraulic hoses to other components, ensuring the smooth transmission of hydraulic power. Depending on the type of equipment and working conditions, there are various ways to connect hoses to fittings and fittings to other parts. Therefore, selecting the right type of fitting must be done carefully based on actual needs.

A hydraulic hose assembly is made by connecting a hydraulic hose to a fitting. It is mainly used to link parts such as hydraulic pumps, valves, and actuators, allowing the flow of hydraulic fluid. A hose fitting must have enough pressure resistance, and more importantly, it must ensure tight and stable connections. This makes the fitting a key component, as it connects the hose to the rest of the hydraulic system (such as pumps, valves, and actuators), ensuring efficient fluid transmission.

Hydraulic fittings are essential components used to connect hydraulic hoses to each other or to hydraulic parts. Among them, fittings for flexible hoses are a major type. One end of such a fitting is specially designed to connect with the hydraulic hose (called the tail end), while the other end connects to other hydraulic components (known as the terminal end). To ensure compatibility with other parts and prevent leaks, the terminal end of a hydraulic hose fitting must follow standard interface guidelines during design and manufacturing. The tail end's main role is to provide a long-lasting and reliable seal between the fitting and the hose.

Based on how they connect, hose fittings can be divided into several types, including crimped fittings, reusable fittings, internal lock fittings, and push-in fittings. Among these, crimped hose fittings are the most common and widely used type.

Types of Crimped Hydraulic Hose Fittings

Based on structural differences, crimped hose fittings can be divided into two main types: one-piece crimped fittings and two-piece crimped fittings.

1. One-Piece Crimped Fittings

One-piece crimped fittings are designed as a single unit, with the fitting stem and ferrule formed together. This structure simplifies the manufacturing process, as no extra parts are required during hose assembly. Under pressure from the eight-segment crimping die of the crimping machine, the one-piece fitting and the hose are compressed together to form a single unit.

2. Two-Piece Crimped Fittings

Two-piece crimped fittings consist of several components, including the fitting stem, sleeve (ferrule), and nut. This design offers greater flexibility. During assembly, the stem, hose, and sleeve are combined, then compressed using the crimping machine. The pressure forms a tight connection between the hose and the fitting, completing the hose assembly. Two-piece fittings are suitable for hoses of different diameters and are often used in high-pressure environments, making them ideal for a wide range of applications.

Crimping Types for Hose Fittings

The crimping method directly affects the sealing performance and pressure resistance of the hose-fittings connection. Based on the hose structure (especially the inner and outer rubber layers) and the pressure level of the hydraulic system, crimping methods are generally classified into three types:

1. Non-Skive Crimping

In non-skive crimping, the outer rubber cover (protective layer) of the hose is left intact during crimping. This method is typically used for low-pressure hydraulic hoses where the outer layer is needed for protection and durability.

2. Outer Skive Crimping

Outer skive crimping removes the outer rubber layer, allowing the fitting to make direct contact with the hose’s reinforcement layer, such as steel wire or fiber. This method is more suitable for medium- to high-pressure applications. It enhances the sealing and pressure-bearing performance, improving the safety of hydraulic systems under higher pressure.

3. Full Skive (Inner and Outer) Crimping

Full skive crimping removes both the inner and outer rubber layers, exposing the metal reinforcement of the hose. This ensures direct contact between the fitting and the wire layer, resulting in the strongest bond and best sealing performance. It is typically used in extremely high-pressure or harsh working conditions, where maximum reliability is required.

Classification of Hose Fittings by Connection Type

1. O-Ring Face Seal Hose Fittings

In this type of connection, as the nut is gradually tightened onto the external thread of the fitting body, the end face of the hose fitting comes into contact with the fitting body and is pressed tightly against it. During this process, the O-ring on the end face of the fitting body deforms elastically and fits closely with the corresponding surface and another O-ring, creating sufficient pressure to form an effective seal.

Note: It is important to carefully inspect the O-ring before installation to ensure it is intact and capable of providing a proper seal.

2. 24° Cone Seal Hose Fittings

When the nut is tightly screwed onto the fitting body, the outer cone of the hose fitting presses against the inner cone of the fitting body. As the tightening torque increases, the O-ring located on the outer cone of the hose fitting undergoes noticeable elastic deformation. This allows it to make full and tight contact with the mating surfaces, generating high contact pressure for excellent sealing.

Thanks to the lever effect of the conical surface, the contact pressure is further amplified, enhancing the sealing performance.

Note: Before installation, always inspect the O-ring to ensure it is undamaged and functional.

3. Flange Hose Fittings

In this type, the flange head of the hose fitting is firmly clamped onto the port surface by a flange clamp. As the bolts are tightened, they create a strong preload force that is transferred through the flange clamp, securely pressing the flange head onto the port. The O-ring on the flange head deforms under pressure, tightly sealing the flange face against the port face.

Due to the use of high-strength bolts, this connection provides very high contact pressure and excellent sealing performance.

Note: Be sure to inspect the O-ring on the flange face prior to installation to confirm its integrity.

4. Threaded Stud Hose Fittings

These fittings use an O-ring or sealing washer placed at the root of the thread. When the fitting is screwed into the port, the O-ring is compressed against the port face, forming a reliable seal.

5. 37° Flare Hose Fittings

As the nut is tightened onto the external thread of the fitting body, the outer cone of the hose fitting comes into contact with the inner cone of the steel tube and is gradually compressed. This contact produces high pressure between the two conical surfaces, ensuring an effective seal.

The lever effect of the conical interface further increases the contact pressure, enhancing the sealing reliability of the connection.

Classification by Connection Method

Connection Methods Between Hose Fittings and Other Hydraulic System Components

1. Threaded Connection

Threaded connection is one of the most common methods used in hydraulic hose fittings. Depending on the thread standard, it can be further divided into several types:

-

Metric Threads: Follow metric standards and are suitable for internationally used hydraulic systems.

-

British Standard Threads: Used in hydraulic systems with imperial units, commonly found in equipment from the UK and parts of the Americas.

-

American Standard Threads: Designed according to U.S. standards and widely used in the United States and some Asian countries.

Threaded connections are typically used in situations that require precise installation and removal. They offer strong connections and reliable sealing performance.

2. Flange Connection

Flange connections are often used in hydraulic pipelines, especially in high-pressure and high-flow systems. The flange fitting connects the hose to other components using a flange, bolts, and sealing gaskets.

Its main advantages include the ability to handle high pressure and the convenience of quick disassembly, making it ideal for large machinery and industrial equipment.

3. Swivel (Articulated) Connection

Swivel connections are used in systems that require flexible movement or need to withstand torque. With a swivel structure, the connector can rotate and move within a certain angle range. This type is commonly found in equipment that needs a high degree of motion flexibility.

4. Quick Coupling Connection

Quick couplings are designed for applications that require frequent connection and disconnection. They allow fast operation through simple push-pull actions.

Common types include automatic locking and manual locking couplings. Quick couplings often feature inner and outer ring seals to ensure good sealing even under high pressure.

Classification by Function and Application

Depending on their function and usage scenarios, hydraulic hose fittings come in different shapes. The most common types include straight fittings and elbow fittings.

1. Straight Fittings

Straight fittings are used for linear connections between two pipe sections or hydraulic components. With a simple structure and easy installation, they are widely used in standard hydraulic systems where the piping follows a straight path.

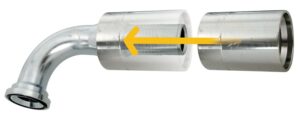

2. Elbow Fittings

Elbow fittings are designed to change the direction of fluid flow, especially in tight spaces or where redirection is needed. Common elbow angles include 45° and 90°, making them ideal for hydraulic systems that require turning. These fittings help solve layout challenges in compact or complex hydraulic setups.

How to Choose the Right Hydraulic Fitting

When selecting a hydraulic hose fitting, it is important to consider a range of factors to ensure suitability and reliable performance. These factors include the maximum working pressure of the fitting, operating temperature, interface size, inner and outer diameter of the hose, ease of installation, and cost-effectiveness.

In particular, the fitting's maximum working pressure must not be lower than that of the connected hose. This is a key requirement for maintaining the safety and stability of the entire hydraulic system.

By carefully evaluating all these aspects, users can choose fittings that meet the specific needs of their applications while ensuring efficient and reliable sealing performance over long-term operation.