In an industrial environment with complex equipment and changing working conditions, hose color coding has become the fastest way to identify different media, pressure levels and functional areas. Through scientific and reasonable color allocation, operators can more quickly identify the purpose of hoses, avoid incorrect connections, and effectively prevent system failures and safety hazards.

This article will explore the core meaning and industry standards of hose colors, covering the color usage logic of various scenarios from high-pressure hoses in hydraulic systems to garden hoses, fire hoses, and hose protective covers, helping you understand how to improve system efficiency, safety, reliability and visual consistency through "color".

Hydraulic Hose Color Coding

Hydraulic hoses are pipes that transmit fluid power, allowing complex systems to operate efficiently and reliably. Hydraulic hose color coding facilitates identification: Hoses are color-coded for quick identification, ensuring that the correct hose is used in the right application. This reduces the risk of errors during installation and maintenance and is essential to ensure that hose assemblies perform as expected.

Purpose of Color Coding

Helps to quickly and accurately identify hoses:

Color coding acts as a visual cue to help operators and maintenance personnel quickly identify specific hoses, which is particularly useful in complex systems that use multiple hoses, each carrying a different fluid or operating under different repulsions.

Safety is improved by reducing the risk of incorrect connections:

By clearly distinguishing between hoses, color coding reduces the likelihood of incorrect connections. This is critical to preventing cross-contamination of fluids or accidental connection to high-pressure lines, both of which can cause system failure or safety hazards.

Industry Standards for Common Hydraulic Hose Color Codes

Overview of Standard Color Codes Used in the Industry:

The hydraulic industry generally follows standardized color codes to maintain consistency and ensure that hoses are easily identifiable across different systems and applications. For example:

Red

This symbol is often used for pipes from the pump to the pressure relief valve to the first section of the flow restriction, indicating the operating system pressure of the fluid.

Blue

Blue is used to indicate that the flow is unrestricted and the fluid pressure is small.

Green

Green indicates that the fluid is drawn from the reservoir to the pump.

Yellow

Yellow indicates the flow of the controlled fluid after passing through the flow restriction valve.

Orange

Orange indicates the flow of the fluid with reduced system pressure, such as the flow of the pressure regulating valve.

Purple

Purple indicates the increase in fluid pressure due to the increase in system pressure.

White

White indicates that the fluid pressure in the system is zero or no pressure

An explanation of what each color typically represents:

Each color in the coding system typically corresponds to a specific characteristic of the hose, such as

Pressure rating: Color coding helps identify hoses for specific pressure ranges, ensuring they are used correctly in high- or low-pressure applications.

Fluid type: Different colors may indicate the type of fluid the hose is conveying, such as hydraulic oil, coolant, or air, helping to prevent cross contamination and ensure the correct fluid is used in the correct application.

Benefits of Implementing Color Coding

Improves Workflow Efficiency:

Color coding allows for quicker hose identification, reducing the time required for installation, inspection, and maintenance. This improves workflow efficiency, especially in environments that require quick turnaround.

Minimizes Downtime by Reducing Connection Errors:

By minimizing the potential for incorrect connections, color coding reduces the likelihood of errors that can lead to system malfunction or failure. This in turn helps keep machines running smoothly and minimizes costly downtime.

Enhanced Maintenance Procedures:

Maintenance personnel can quickly identify hoses that require inspection, replacement, or maintenance based on color coding, streamlining maintenance processes and ensuring the right hoses are serviced at the right time.

Colored Rubber Garden Hose

Garden hoses are ornamental in nature and come in many colors, such as red, yellow, blue, green, etc., to match the style of your garden. Sinopulse offers high-quality, colorful rubber garden hoses for gardens. The rubber garden hoses we produce are naturally strong and durable, and will not be squeezed or kinked like vinyl hoses, and can be easily rolled up even in cold weather.

Colored Fire Hose Hoses

Colored series jet hoses are fire hoses that come in eight easily distinguishable colors. In addition to the eight standard colors, we can also customize transparent or custom colors based on customer requirements. There is the commonly used red, as well as blue, yellow, green, dark green, brown, orange, purple, black, white, etc.

Advantages of fire hose color differentiation

Different colors allow hoses to be easily divided and distinguished based on location, purpose or year of purchase, etc.

The colored polymer is deeply absorbed by the jacket, so the color will not fade or change over time due to exposure to UV rays.

The surface coating effectively enhances the wear resistance of the hose.

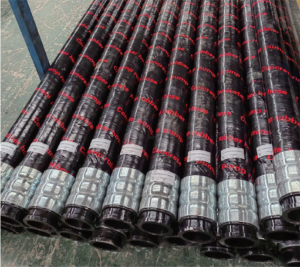

Colored Hose Protectors

Protective sleeves can be used to identify hoses to reduce the possibility of mixing, contaminating products, or to designate hoses for specific applications or uses.

Advantages of using different colored hose covers

Hose application: blue for water, yellow for fuel, green for sewage Connection points can be the same color as the covers on the hose to ensure proper connection Hoses with specific chemical compatibility can be painted with colors unique to specific chemicals Colors can be used to identify which hoses belong to a specific application unit or truck. For example, if all hoses on a 35 truck have blue covers, the operator can quickly ensure the correct hoses before the truck sets off. When working on a job site with multiple operators, if all hoses have red covers, you can quickly find all hoses to prevent loss or theft.

Color-coordinated covers can enhance appearance and keep in line with the color scheme and design: Your new equipment looks beautiful with a new coat of paint, but once the hoses are installed, a variety of black, blue, green and red hoses, each with routing from a different manufacturer, will distract from your otherwise well-designed and well-constructed machine. Not only does it organize the scattered hoses, it also protects the hoses from weathering and damage.

quick view of common hose colors used in other applications

Industrial sector (globally used)

| COLOR | APPLICATION |

|---|---|

| Black | The most common, suitable for general industrial multi purposes, such as air, water, oil, etc.; mostly used in Europe and America, Southeast Asia, the Middle East, etc. |

| Red | Steam hose (especially for European and American markets), high temperature applications or hazardous area warnings |

| Blue | Cold water, food grade water line, air conditioning system |

| Yellow | Gas/LPG hoses, mining hoses (such as Australia) |

| Green | Chemical hoses, garden hoses, agricultural irrigation (especially Brazil, India) |

| Gray | Drain hose, concrete hose or wear-resistant hose (such as German market) |

| Orange | High-voltage pneumatics, power line protection (such as South Korea, Southeast Asia) |

| White (translucent) | Food grade hose, commonly used in dairy products and beer transportation (such as Europe and Russia) |

Agriculture & Farm Machinery

| Area | Color | Usage |

|---|---|---|

| Brazil, Argentina | Green, Blue | Pesticide, water and fertilizer transportation |

| India | Green, yellow, red | Irrigation, fertilizer and water mixing |

| USA | Black with colored stripes (such as green, red, yellow) | Multifunctional agricultural hose |

| Some African countries | Yellow, red | High-temperature and sun-resistant, low-cost irrigation hose |

Mining & heavy industry (e.g. quarries, oil fields)

| Area | Color | Usage |

|---|---|---|

| Australia | Yellow, black with red stripes | High wear-resistant delivery hose |

| South Africa | Red, Orange | High-pressure air delivery, drilling equipment connection |

| Canada | Black, Red | Dedicated for oil fields, drilling |

Construction & Concrete Industry

| Color | Usage |

|---|---|

| Black with yellow stripes | High-pressure cement delivery hose (such as Germany and Poland) |

| grey | Concrete pump hose, easy to identify residual material blockage |

| blue | Certain building compressed air lines |

Food/Pharmaceutical Industry

| color | usage |

|---|---|

| White/transparent/blue lining | Food grade hose (Europe, America, Japan, etc.) |

| Red or green outer layer | Used to distinguish between hot and cold wires (Europe, America, Japan, etc.) |

| Commonly used white, transparent, blue, some manufacturers can customize the color | For food delivery, China and Southeast Asia |

Sinopulse is a professional hydraulic hose and industrial hose manufacturer and exporter with more than 20 years of experience in China. We provide you with one-stop production, procurement services for all hydraulic hoses, industrial hoses and fittings accessories.

Our hose products in different colors are widely used in agriculture, construction, coal mining, machinery, garden industry, automotive industry, oil and gas industry.

With competitive prices, stable product quality and timely delivery, we have established long-term business relationships with customers from more than 50 countries.

With our technology and advanced production lines, we can produce hoses that meet any standard or customized color specifications, and pay attention to every detail throughout the process to ensure product quality. If you are looking for a reliable manufacturer of hoses in different colors, please feel free to contact us, we will provide the best solution for your hydraulic system.