Hydraulic Fittings

Hydraulic hose fittings are components used to connect hoses, pipes, and tubes in hydraulic systems. They are often used to join two sections of a hydraulic hose together or to connect a hose to a port or adapter.

Hydraulic fittings are critical components in a hydraulic system, serving as conections between hoses, pipes, and other components. These fittings ensure the safe flow of hydraulic fluid, which is critical to the overall function of the system.

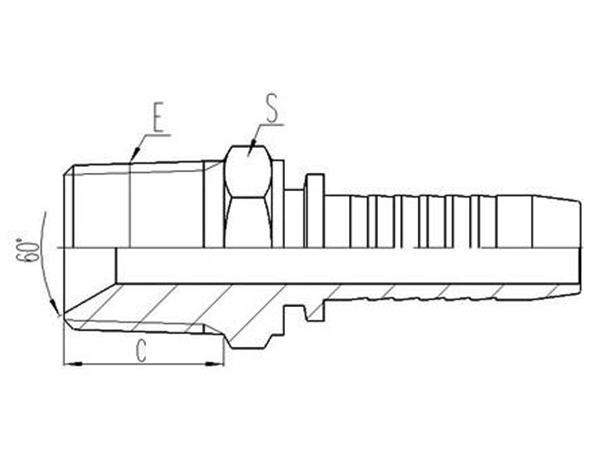

Hydraulic fittings are precision connectors used to connect hoses, pipes and tubes in hydraulic systems, ensuring leak-proof, secure connections under high pressure. Designed to withstand tremendous pressure, these fittings come in a variety of shapes and sizes, including elbows, tees, unions and adapters, to meet specific system requirements. Hydraulic fittings come in various shapes and sizes and are made from multiple materials, including brass, steel, stainless steel, and plastic. They are designed to withstand high pressures and temperatures and are often used in industrial and automotive applications. Hydraulic hose fittings include JIC, SAE, NPT, and BSP.

Our standard hydraulic fittings are as follows:

Ferrule, Metric Fittings, British BSP Fittings, American SAE, ORFS, NPSM, JIC, NPT Fitting, SAE Flange, JIS Fittings, Staplelok Fitting, Banjo, Double Connection, Reusable Hose Fitting

Advantages of Using Hydraulic Fittings:

1. Hydraulic fittings are designed to provide a secure and leak-proof connection between two hydraulic components. This ensures that the hydraulic system operates efficiently and safely.

2. Hydraulic fittings are designed to withstand high pressure and temperature, making them ideal for various applications.

3. Hydraulic fittings are easy to install and require minimal maintenance.

4. Hydraulic fittings are available in a variety of sizes and configurations, making them

Sinopulse is your comprehensive source for hydraulic hoses, fittings, adapters, quick disconnects and more! With over 15 years of experience in the industry, we are dedicated to expanding our selection to meet the needs of our customers.

From crimp and reusable fittings, quick disconnect couplings to steel adapters and more, Sinopulse delivers an incredible range of fittings and connectors for virtually any application to help you make the right connection every time. We can provide the hose and fittings that meet global performance standards, right when you need them. We include a broad selection of hydraulic assembly equipment, andwe can also produce a high-quality, reliable hydraulic hose assembly while you wait.

Our hydraulic hose fittings range includes 1SC, 2SC, 100 R7, 4SP, 4SH & suction & delivery hose, along with compatible hose inserts and ferrules.

If you’re not sure what type of hydraulic hose fitting you should be using for your application, please get in touch and we will provide you with the correct hose and fittings for the job!

We don’t only supply loose hydraulic hose and fittings, we can also make bespoke hose assemblies to your given specification.

Contact us today for further information

Hot Products

Related Product

What are hydraulic hose fittings

Hydraulic hose fittings connect hoses to pumps, valves, cylinders and other components used throughout a hydraulic system. These secure connections help control and direct the flow of hydraulic fluid to where it is needed, while preventing leaks and safely maintaining pressure.

Application of hydraulic hose fittings

Hydraulic hose fittings are widely used in various industries. The applications of hydraulic hose couplings are as follows:

1. Construction machinery

In construction machinery, the hydraulic system is very important. Heavy equipment and cranes use hydraulics to control large loads, and excavators use hydraulics to dig the ground.

These machines can be used with different attachments, and hydraulic hose fittings can easily connect these attachments.

2. Industrial machinery

In industrial machinery, hydraulics are used to control mechanical pressure. Presses use hydraulics to generate force to form metal and robot arms use hydraulics to achieve complex movements. These hydraulic hoses are usually connected through hydraulic hose fittings.

3. Agricultural Machinery

Hydraulics are also used in agricultural machinery to control the movement of tractors and combines. Tractor blades and excavators are hydraulically operated and are used to plough fields. Hydraulic hose fittings are components that connect different attachments and equipment to assist in the various functions of agricultural machinery.

Types of Hydraulic Hose Fittings

There are several types of hydraulic hose fittings designed to meet different standards and applications. The following are the types of hydraulic hose fittings:

1. NPT Thread Fittings

NPT thread is a standard used primarily in the United States. It has a tapered female thread designed to fit snugly into the male thread. It is commonly used in liquid and gas handling applications.

2. Unified Thread Fittings

Unified thread is a widely used international standard. There are two types of Unified Threads: Fine Unified Threads (UNF Threads) and Coarse Unified Threads (UNC Threads), each of which is selected for a specific application. These threads have a straight connection and may require additional sealing material to form a seal. 3.

3. DIN Metric Thread Fittings

DIN metric threads are a standard for metric threads designed according to the German DIN standard. It consists of different variants of metric threads, expressed in the form of M10x1.5, etc. It is widely used in the assembly of machinery and equipment. It is widely used for assembling machinery and equipment, especially in Europe.

What do the numbers on hydraulic fittings mean?

The numbers on hydraulic fittings indicate the size and type of fitting. They indicate the fitting's thread size, pitch, and compatibility with other components.

How do I determine the size of a hydraulic hose fitting?

To determine the size of a hydraulic hose fitting, measure the hose's inside diameter (ID) to ensure compatibility with the fitting, and use a thread gauge or identification tool to verify the fitting's thread type and size. Also, consider the hose's pressure rating and application to select a fitting that meets or exceeds the system's requirements.

How do I know what size hydraulic fitting I need?

To determine the correct size hydraulic fitting, use a caliper and pitch gauge to measure the fitting's threads' outside diameter (OD) and pitch (the distance between threads). Consult a size chart or manufacturer's specifications to match these measurements to the appropriate fitting size.

What are the basics of hydraulic fittings?

Hydraulic fittings are components used to connect hoses, pipes, and tubes in hydraulic systems to ensure safe, leak-free flow of hydraulic fluid. They come in a variety of types, such as threads, crimps, and flanges, and are made from materials such as steel, brass, or stainless steel to withstand high pressures and corrosive environments. Proper selection and installation of hydraulic fittings are critical to maintaining system integrity and performance.

How do I identify the type of hydraulic fitting?

To identify the type of hydraulic fitting, you can look at the thread type (such as NPT, BSP, or metric), sealing method (such as O-ring, metal-to-metal, or tapered), and fitting shape (such as elbow, tee, or straight). In addition, checking the manufacturer's specifications and using a thread gauge can help ensure accurate identification.

How do I identify hydraulic fittings?

To identify hydraulic fittings, check the thread type, size, and sealing method, such as O-ring, metal-to-metal, or tapered threads. In addition, use identification tools such as thread gauges and calipers, and consult fitting diagrams or manufacturer specifications to ensure an accurate match.

How do hydraulic fittings work?

Hydraulic fittings are components used to connect hoses, pipes, and tubes in hydraulic systems to ensure a secure and leak-free connection. They withstand high pressures and facilitate the flow of hydraulic fluid by using various sealing mechanisms, such as O-rings or metal-to-metal contact. Proper selection and installation of these fittings are critical to maintaining system integrity and performance.

How do I choose a hydraulic hose fitting?

When selecting hydraulic hose fittings, consider hose size, pressure rating, and compatibility with the fluids being used. Also, make sure the fitting type matches the hose and equipment connection, and select materials that will withstand the operating environment and conditions.

How to choose a suitable hydraulic hose fitting manufacturer in 2024

Where to choose a suitable hydraulic hose fitting manufacturer

While the market is developing steadily, it is very important to choose a suitable hydraulic hose fitting manufacturer in the face of the increasingly competitive market. So how to choose a suitable hydraulic hose fitting manufacturer?

B2B platform

B2B platform gathers a lot of hydraulic hose fitting manufacturer with a wide range of users, but customers generally enquire in a wide range of ways and the quality is not high.

Generally speaking, the brand manufacturer website searched through Google is still more professional, faster and more professional than B2B platform.

Have you ever tried to choose China hydraulic hose fitting manufacturer?You may be influenced by what other people say, but China hydraulic hose fitting is actually competitive, most reliable and trustworthy.

Give you two reasons to choose hydraulic hose fitting manufacturer in China:

China has the most complete industrial chain in the world, and the industry has reached the world-class level after decades of rapid development. China has a huge cost advantage, which is not only reflected in the labour cost, but also China has a large number of talents, complete supply chain, excellent production technology, which gives China manufacturing a huge cost advantage. There are many other factors that make the technology and level of Chinese hydraulic hose fitting manufacturers rise to the forefront of the world and become the best choice for global customers.

Select professional hydraulic hose fitting manufacturer features

Hose fittings are manufactured from high quality materials and meet all SAE, DOT and other industry requirements. They are specially tested to operate at extremely high pressures.

Flexible for many applications and hose styles, including socketless, braided, spiral and PTFE.

For longer life and leak-free operation

Exceed your needs in the harshest environments, from construction, oil and gas, mining and manufacturing to transport.

Specialised production lines: 18,000 square metres of plant, 200 machines, 100 employees and 40,000 commonly used items in stock.

Most common international standards can be met, as well as the specific requirements of several of our major OEM customers.

A clear understanding of their needs, resulting in efficiency, stability and satisfaction for the manufacturer

Sinopulse - your professional hydraulic hose fitting manufacturer

Sinopulse is an employee-owned manufacturer in China, specializing in contract machining, aluminum die casting, and hydraulic hoses. With over 500,000 square feet of manufacturing space and 500 workers. The company's legacy of quality products makes them a trusted partner for businesses. Sinopulse offers a comprehensive line of tractor hoses and couplings. With a large stock of hydraulic hoses, they ensure timely deliveries, allowing farmers to focus on their work rather than equipment.

Founded in 2011, Sinopulse hose factory specializes in the manufacturing and supply of hydraulic fittings, adapters and hoses for Original Equipment Manufacturers (OEMs) and distributors worldwide. We offer a broad range of hydraulic fitting types, including JIC, ORFS, Metric, and many others, designed to meet the rigorous standards of the industry.

We are proud to serve major markets including construction, agriculture, forestry, mining, material handling, marine, and more, providing reliable and robust hydraulic connections that enhance the functionality and durability of hydraulic systems.

Our longstanding collaboration with our customers for specially designed hydraulic applications has positioned Sinopulse fitting as a preferred hydraulic adapter fittings manufacturer in the industry. We are experts in creating both standard and custom solutions that cater to a wide range of applications, ensuring optimal performance in even the most demanding environments.

Quick Fitting Production: At Sinopulse, we understand your customers count on you to get them the products they need quickly and affordably, no matter when the order comes in. Our quick production ensures our products are reliable, on-hand, and ready to ship — reducing overall downtime for your customers. We specialize in short lead times, expediting, and drop shipping, which ensures orders are fulfilled on time. Whether you need a part for repair or to order new fittings, our comprehensive inventory and dedicated team of specialists will assure you have the products you need as quickly as possible.

Custom fitting solutions: As the demands of the industry evolve, so do the needs of our customers. Sinopulse doesn’t just supply; we actively collaborate to provide custom solutions that adapt to these changing requirements. Our engineering and design services team is dedicated to understanding your unique challenges and delivering precise, tailored solutions that exceed expectations.

Our online catalog represents only a portion of what we manufacture and offer. We specialize in handling special requests based on your application.