Oil & Gas Hose

One of the largest hose products produced by Sinopulse is Petroleum & Oilfield Hoses. The hoses in this portfolio are used in a wide range of applications from drilling to production, refining to delivery.

When you are dealing with the high pressure demands of the gas and oil industry, a quality hose or fitting is the one you need to produce efficiently. That’s why Sinopulse has built a full line of high-quality hoses and fittings to outlast and outperform them all.

Our wide range of oil, waste and water hoses covers every aspect of oil and gas extraction and processing. We have designed and manufactured hose products that are tailor-made for this market application.

Improve the way you work with Sinopulse’s Petroleum & Oilfield Hoses.

- Extremely flexible. Excellent minimum bend radius

- Cover is weather, abrasion and weather resistant

- Heat, ozone and salt water resistant

- Operating temperature: -40°F (-40°C) to +194°F (+90°C)

- Anti-static copper wire grounds the hose

- Safe Ohm (SΩ) grounding wire is embedded in the hose wall to help prevent static buildup. The SΩ wire must be secured to ground to dissipate static electricity.

- 4:1 safety factor

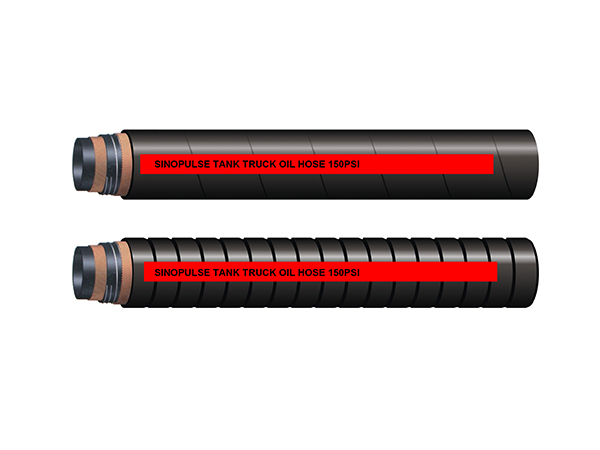

TANK TRUCK OIL HOSE 150psi

Hardwall hose designed for suction and delivery of a wide range of petroleum

fuel with aromatic content up to 50% for tank trucks.

Hot Products

Stages of the Drilling and Completion Process Where Hoses Are Required

Several stages of the drilling and completion process require rugged hoses that are durable and can withstand the rigors of the environment near the drill bit and the media flowing through them. These stages include:

At the top of this hose lineup is the Frac Hose, a hose that carries a variety of media and is expected to carry water, sand, and various frozen chemicals at high pressure. A series of tanks on site are connected to hundreds of feet of hose and are sent to a common mixer before being pressurized for delivery downward.

Oil hoses and chemical processing hoses are also in great demand. Fracking refers to opening up rock formations to release natural gas through hydraulic fracturing.

Delivering water to mix diamonds and fracturing fluids (including sand, chemicals, and water)

Pumping drilling mud.

Pumping concrete downhole.

High-pressure pumping of fracturing fluid downhole.

Hoses deliver water to the site.

petroleum transfer and suction hoses

For petroleum transfer and suction hoses, the types of hydraulic hoses used are specifically designed to handle the transfer of petroleum-based fluids, such as oils, gasoline, diesel, and other petroleum products. These hoses must be resistant to abrasion, corrosion, and chemical attack, while also being flexible and capable of withstanding high pressure and suction applications.

- Chemical Resistance: Must be able to resist attack from fuels and oils, including gasoline, diesel, and other petroleum-based products.

- Temperature Resistance: Petroleum transfer hoses are often used in a wide range of temperatures, so the hose should be able to handle both high and low temperatures.

- Abrasion Resistance: The hose should be durable enough to withstand the rough handling in industrial environments and the wear from fluid transfer.

- Flexibility: Flexible construction is essential, especially in applications where hoses need to be easily maneuvered and connected to various equipment.

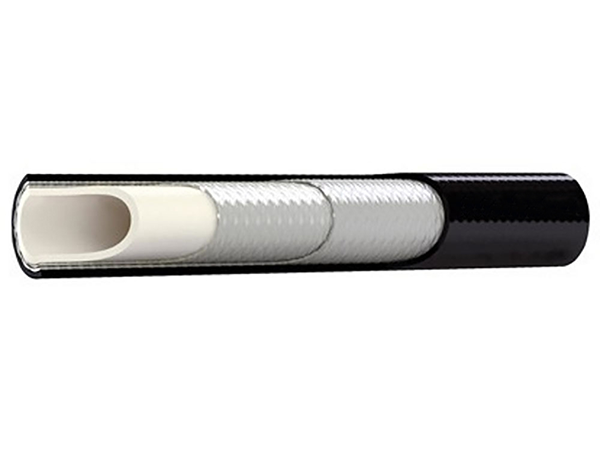

- Reinforcement: Reinforcement layers, such as steel wire or textile braiding, help prevent the hose from collapsing during suction or from bursting under high pressure.

Here are the typical types of hoses used for petroleum transfer and suction:

1. Petroleum Transfer Hose

Petroleum transfer hoses are used for the transportation of oil, gasoline, diesel, and other fuels in various industries, including refineries, fueling stations, and tanker loading/unloading.

-

SAE 100R4 (Suction and Return Hose):

- Description: Reinforced with a textile braid or spiral, suitable for suction and return lines.

- Application: Commonly used for petroleum transfer in low- to medium-pressure systems, such as fuel dispensing, tank trucks, or refinery systems.

- Pressure Rating: Typically up to 1,000 psi.

- EN Equivalent: EN 854 1TE (Suction and return line hose).

- Additional Features: Oil-resistant rubber, often has a smooth or corrugated exterior for flexibility.

-

SAE 100R5 (Wire Braided Hose):

- Description: A medium-pressure wire-braided hose, designed for general petroleum product transfer.

- Application: Ideal for higher-pressure transfer lines, including bulk fuel transfer from tankers, refineries, and oil terminals.

- Pressure Rating: Typically up to 2,000 psi.

- EN Equivalent: EN 857 2SC (Two steel wire braid construction for medium pressure).

-

SAE 100R12 (Wire Spiral Hose):

- Description: A high-pressure hose reinforced with multiple layers of steel wire spiral.

- Application: Used for high-pressure fuel transfer systems, such as offshore platforms or deepwater drilling operations where a high level of pressure resistance is required.

- Pressure Rating: Typically up to 6,000 psi.

- EN Equivalent: EN 856 4SP (Four steel wire spiral reinforcement for high-pressure applications).

2. Petroleum Suction Hose

Petroleum suction hoses are designed to handle both the suction and discharge of petroleum products, and they are typically used for applications like tank truck unloading, refinery operations, or tank farm transfer.

-

SAE 100R4 (Suction Hose):

- Description: A reinforced hose specifically designed for suction and low-pressure discharge of petroleum fluids.

- Application: Commonly used in tank trucks, refueling systems, and mobile oil transfer applications.

- Pressure Rating: Typically up to 1,000 psi.

- EN Equivalent: EN 854 1TE (Suction and discharge hose).

Oilfield cleanup and spill recovery hoses

Oilfield cleanup and spill recovery hoses are specialized hoses used for handling oil, chemicals, and hazardous materials during cleanup and recovery operations on oilfields. These hoses must be durable, resistant to chemicals, and capable of withstanding the harsh conditions found in such environments, including extreme temperatures, high pressures, and exposure to oil, fuel, and other potentially hazardous fluids.

- Chemical Resistance: These hoses need to be resistant to a wide range of oils, chemicals, and solvents commonly used in the oilfield and spill recovery operations.

- Abrasion Resistance: Due to the rough conditions in oilfield environments, these hoses must have excellent resistance to wear and tear.

- Temperature Resistance: These hoses must withstand extreme temperatures, particularly in oil and gas extraction sites, which can see both high and low temperatures.

- Flexible Construction: Oilfield cleanup hoses must be flexible enough to maneuver in tight spaces and be easily handled during spill recovery operations.

Here are the typical types of hydraulic hoses used for oilfield cleanup and spill recovery:

1. Oilfield Cleanup and Spill Recovery Hose

These hoses are used for the recovery and transportation of spilled oil, chemicals, and other hazardous materials. They are usually designed for heavy-duty operations and need to be resistant to abrasion, chemicals, and oil.

-

SAE 100R4 (Suction and Return Hose):

- Description: Textile braid reinforced hydraulic hose, commonly used for low-pressure suction and return lines.

- Application: Suitable for oilfield cleanup operations where suction and return of petroleum-based products are required. These hoses are flexible and resistant to abrasion and oil.

- Pressure Rating: Typically up to 1,000 psi.

- EN Equivalent: EN 854 1TE (Suction and return line hose).

- Additional Features: Oil-resistant inner lining, flexible outer cover for ease of handling, and durable construction for heavy-duty cleanup operations.

-

SAE 100R12 (Wire Spiral Hose):

- Description: High-pressure hose with multiple layers of steel wire spiral reinforcement.

- Application: Ideal for high-pressure oilfield applications, including spill recovery where high-pressure fluid transfer is required. Often used in oil spill recovery systems and for transferring recovered fluids to storage or disposal containers.

- Pressure Rating: Typically up to 6,000 psi.

- EN Equivalent: EN 856 4SP (Four steel wire spiral reinforcement for high-pressure applications).

- Additional Features: High pressure resistance, enhanced flexibility, and oil-resistant rubber lining.

-

SAE 100R16 (Two-wire Braid Hose):

- Description: Hose with two layers of wire braid reinforcement.

- Application: Suitable for medium-pressure hydraulic systems in spill recovery and oilfield cleanup. Can handle the transport of fluids with moderate pressure requirements, such as oil recovery from surface cleanup operations.

- Pressure Rating: Typically up to 4,000 psi.

- EN Equivalent: EN 857 2SC (Two steel wire braid construction for medium pressure).

- Additional Features: Strong and flexible for use in tough environments, resistant to oil and chemical contaminants.

-

SAE 100R7 (Thermoplastic Hose):

- Description: Thermoplastic hydraulic hose with a smooth, flexible outer cover.

- Application: Often used in spill recovery operations that require flexibility and resistance to oil and chemicals, especially for handling and transferring petroleum-based fluids from recovery locations.

- Pressure Rating: Typically up to 3,000 psi.

- EN Equivalent: EN 854 1TE (Thermoplastic hydraulic hose for medium-pressure applications).

- Additional Features: Lightweight, smooth surface for easier handling, resistant to chemical exposure.

polyurethane (PU) and HD (High-Density) polyurethane gasoline and alternative fuel vapor recovery hoses

For polyurethane (PU) and HD (High-Density) polyurethane gasoline and alternative fuel vapor recovery hoses, these hoses are specifically designed to safely handle fuel vapors during the refueling process, ensuring that toxic vapors are safely recovered and returned to the storage tank. These hoses are generally used in gasoline stations, fuel delivery trucks, and other refueling systems, and must be resistant to both the fuel itself and the vapors produced during the transfer process.

Polyurethane and HD polyurethane are chosen for their abrasion resistance, flexibility, and durability, while also being resistant to the harsh chemicals, oils, and vapors associated with fuels like gasoline and other alternative fuels (such as ethanol, biofuels, and compressed natural gas).

- Chemical Resistance: NBR or similar fuel-resistant materials are used for the inner tube to ensure that the hose does not degrade when in contact with gasoline vapors, ethanol, methanol, or other volatile fuels.

- Abrasion Resistance: The outer cover made from Polyurethane or HD Polyurethane provides high abrasion resistance, essential for hoses that are constantly in motion and subjected to rough handling.

- UV and Ozone Resistance: Polyurethane is highly resistant to UV rays and ozone, ensuring longevity when exposed to outdoor elements.

- Flexibility: Polyurethane hoses are known for their flexibility, which makes them easier to handle in dynamic environments like fueling stations or truck fueling operations.

- Temperature Range: These hoses are designed to withstand a range of temperatures, typically from -20°C to +80°C (-4°F to 176°F), depending on the specific formulation.

Types of Hydraulic Hoses Used for Polyurethane and HD Polyurethane Gasoline and Alternative Fuel Vapor Recovery:

1. SAE 100R7 (Thermoplastic Hose)

- Description: A thermoplastic hydraulic hose typically used for medium-pressure applications. It is often reinforced with a fiber braid or wire for flexibility and strength.

- Application: Used for fuel vapor recovery systems where the hose must transfer vapor and low-pressure fluids in a safe, controlled manner. It is ideal for the transfer of gasoline vapors or alternative fuels and is commonly seen in vapor recovery hoses at fuel stations.

- Pressure Rating: Typically up to 3,000 psi.

- EN Equivalent: EN 857 1SC (Two-wire braided hydraulic hose for medium-pressure applications).

- Material: Polyurethane or HD Polyurethane outer cover for flexibility, abrasion resistance, and UV stability. The inner tube is often NBR (Nitrile Butadiene Rubber) or another fuel-resistant material to handle gasoline and alternative fuels.

2. SAE 100R6 (Low-Pressure Hose)

- Description: A lightweight, textile-reinforced hose designed for low-pressure applications.

- Application: This hose can be used in vapor recovery systems that operate under lower pressures, such as fueling stations that need to handle gasoline vapors during the refueling process. It is suitable for recovery lines and also for systems involving alternative fuels like ethanol or methanol.

- Pressure Rating: Up to 1,000 psi.

- EN Equivalent: EN 854 1TE (Textile-braided hose for low-pressure fluid handling).

- Material: The hose will have a Polyurethane or HD Polyurethane outer cover for flexibility, oil resistance, and abrasion resistance. The inner tube often features NBR for gasoline and fuel resistance.

3. SAE 100R4 (Suction Hose)

- Description: Reinforced with a textile braid or spiral for low-pressure suction and discharge applications.

- Application: Often used for the suction of gasoline vapors and fuel vapor recovery. These hoses are used in fuel stations or tanker trucks to prevent vapor emissions and ensure safe transfer of volatile fuels.

- Pressure Rating: Typically up to 1,000 psi.

- EN Equivalent: EN 854 1TE (Suction and return line hose).

- Material: Polyurethane or HD Polyurethane outer cover to resist UV, ozone, and chemical exposure. The inner lining is designed to handle gasoline vapors.