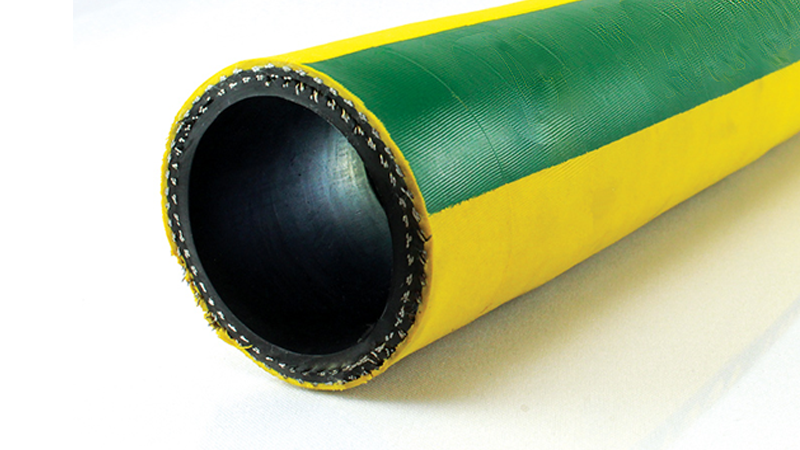

Air Hose 400psi

Construction

Tube: Nitrile Blend rubber, oil mist resistant, smooth. High-strength, versatile and oil resistant

Cover: Yellow SBR rubber, weather, ozone, and abrasion resistant, wrapped finish, pinpricked. Abrasion, weather, and ozone resistant

Reinforcement: 1ply, 2ply or 4ply High strength polyester woven synthetic fabric braided reinforcement. Adds extra strength and resilience.

Features:

I.D rang: 16/3"- 2"

Working pressure: 400PSI

Safety factor: 3:1

Temperature range: -30°C(-22F)to+80°C(+176°F)

Application: For tough applications in mines and quarries.

Branding: Sinopulse or customized

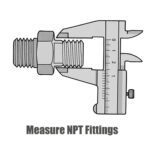

Typical Fittings: 1/2-1" universal fitting (not 1-1/4-2" 4-lug fitting, see coupling warnings), double lock/twist lock, N176 hex fitting, N315/320 long shank (water only), 1/2"-1" hose punch clamp/crimp sleeve, ground joint interlock bolt clamp coupling (re-tighten before each use due to cold flow/set of rubber hose). Crimp sleeves are not recommended on 1-1/4"-4" HD air due to wall thickness and temperatures - use interlock bolt clamps. For more information, you may contact us!

Packaging: 100m long, coiled, plastic wrapped

Specifications of 400PSI Air Heavy Duty Air/Multi-Purpose Hose

| Code | I.D (inch) | I.D (mm) | O.D (mm) | W.P (bar) | W.P (psi) | B.P (bar) | B.P (psi) | L (m) | L (ft) |

| CAH4-005 | 3/16 inch | 4.8 | 12 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-006 | 1/4 inch | 6.4 | 13 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-008 | 5/16 inch | 7.9 | 15 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-010 | 3/8 inch | 9.5 | 17 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-012 | 1/2 inch | 12.7 | 23 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-019 | 3/4 inch | 19.1 | 30 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-025 | 1 inch | 25.4 | 37 | 28 | 400 | 84 | 1200 | 100 | 330 |

| CAH4-032 | 1-1/4 inch | 31.8 | 46 | 28 | 400 | 84 | 1200 | 60 | 200 |

| CAH4-038 | 1-1/2 inch | 38.1 | 52 | 28 | 400 | 84 | 1200 | 60 | 200 |

| CAH4-050 | 2 inch | 50.8 | 68 | 28 | 400 | 84 | 1200 | 60 | 200 |

Advantage

Oil Resistance: Features oil-mist resistance, making it suitable for environments where oil exposure is common.

Covering: Bright yellow non-marking cover for easy identification and durability.

Pressure Rating: Designed for medium-high working pressure, offering reliable performance under normal conditions.

Durability: Weather and ozone-resistant, ensuring longevity even in outdoor environments.

Abrasion Resistance: Excellent resistance to abrasion, enhancing the hose's lifespan and reducing wear and tear.

Use tips

Suitable Applications: Designed for compressed air, ordinary industrial water, and non-corrosive oils.

Storage Requirements: Should be stored in a dry, light-proof place to maintain integrity.

Pressure Limits: Must not exceed the specified maximum pressure, and pressure should be increased gradually to avoid excessive impact.

Temperature Range: Air hoses must be used within the specified temperature range. If the ambient temperature exceeds 80°C, the outer layer of the hose should be insulated.

Operational Conditions: The hose must not be twisted, stretched, or squeezed during use.

Sinopulse Hose Factory

Raw Material:

Imported rubber material Vietnam and Thailand

High tensile strength 2750Mpa steel wire from China's first-class factory

Powerful, safe and stable hydraulic hose products

Good dispersibility, high bearing pressure and superior pulse performance.

Excellent oil resistance, heat resistance and aging resistance.

Excellent bending resistance and fatigue resistance

Factory Workshop:

Sinopulse is a 100% manufacturer of hydraulic hoses and industrial hoses, including all oilfields, agriculture, transportation, construction, mining, and forestry.

Daily output 500,000 meters of hoses, workshop covering 40,000 m²

40 production lines, involving high-speed joint machines, braiding machines, high-speed spiral machines, Italy VP automatic industrial machines, and Complete series Laboratory Testing Equipment

120 Skilled workers, 6 Engineers with 2 technical counselors from famous international companies,2 QC departments, and 2 warehouse managers are fall of our lovely people.

50 Sales and three groups of logistics specialists serve our clients from Italy, Germany, Uk, Spain, the USA, Canada, Brazil, Argentina, Panama, Peru, Chile, Viet Nam, Indonesia, Australia, Romania

Laboratory:

Our factory introduces a full range of laboratory testing equipment. It has advanced laboratory capabilities to conduct product quality testing and research and development work to ensure stable and excellent product quality.

After purchasing raw materials, we test each batch to ensure they meet our product's technical requirements.

After production, we test each hose, its working and burst pressure, and conduct a pulse test for each order to ensure that it is 100% qualified after leaving the factory.

We strive to provide our customers with top-notch hoses, doing everything we can to ensure their quality.

"Let our end users feel comfortable in use and safe in driving!" is our common goal.

Product packaging:

1. When packing hydraulic hoses, cartons or wooden boxes according to customer requirements.

2. We will pack the hose after finishing the hose production.

3. Generally, woven bags and plastic films are used for packaging.

4. Special packaging can be provided according to customer requirements. Special packaging is a request of Edible ACC Ording customers.