Wire Braided Hydraulic Hose

Sinopulse has a full range of steel wire braided hydraulic hoses to meet the requirements of all low, medium and high pressure hydraulic applications. Whether you need high-performance hoses for critical systems or standard hoses for others, Sinopulse can supply.

Wire braid hydraulic hoses can be divided into many types according to the layer number. Here we will introduce two kinds of steel wire wire braid hydraulic hoses that are widely used in the markets. They are namely single wire braid hose and double wire braid hose.

Single and Double Wire Braid Hydraulic Hoses

Sinopulse braided hydraulic hoses are fundamental fluid conveyance solutions for various equipment and applications with wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities.

Sinopulse hydraulic steel wire braided hoses are designed with a safety factor of 4:1 relating minimum burst pressure and recommended working pressure.

Hydraulic hoses are designed for petroleum base hydraulic fluids applications with a temperature range of –40˚C (-40˚F) to +100˚C (+212˚F). Special rubber compounds and other lining materials allow to exceed these limits.

Hydraulic hoses may also be used for water base hydraulic fluids if the working temperature does not exceed +70˚C (+158˚F).

For conveyance of Hot Air working temperature should be reduced to a maximum of +60˚C (+140˚F)

Applications

- Hydraulic system service with petroleum and water-based fluids, for general industrial service.

- Petroleum and fire-resistant hydraulic fluids, fuel and lubricating systems

- Low temperature flexing and hydraulic system service with petroleum and water-base fluids

- Logging, construction, mining and other off highway applications

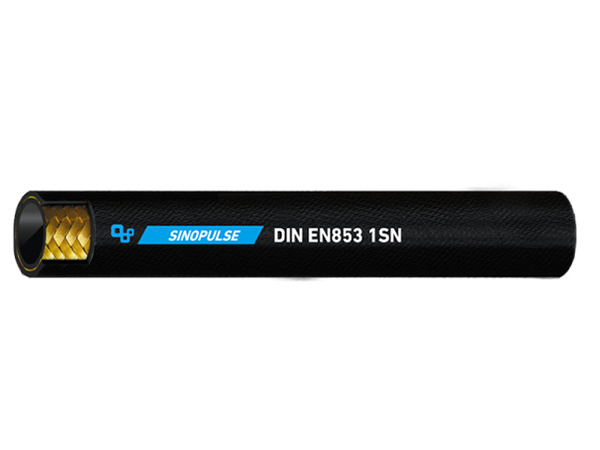

Single-Wire Braided Hydraulic Hose

The single wire braid hydraulic hose is made of oil resistant synthetic rubber lining, single wire braid reinforcement and oil, fuel and abrasion resistant rubber cover.

Low & medium pressurehydraulic systems, petroleum & water-based fluidsconstruction equipment, and agriculture equipment

- Inner reinforcement: 1 Wire Steel Wire Braid

- Outer Cover: MSHA Certified, Vulcanized Abrasion and Weather Resistant Synthetic Rubber

- Temp Operating Range: -40°F/-40°C to 212°F/100°C (+248°F/120°C max.)

SAE 100R1AT single wire braided hydraulic hose

EN853 1SN single wire braided hydraulic hose

EN857 1SC single wire braided hydraulic hose

SAE 100R1 Single Steel Wire Braided Hydraulic Rubber Hose Technical Specification

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m | Codigo | Codigo |

| SAE 100R1-03 | 1SN-03 | 4.8 | 3/16" | 4.6-5.4 | 12.5 MAX . | 250 | 3625 | 1000 | 14500 | 90 | 0.240 | 50/100 | ××××1-××-03 | 00110-03 |

| SAE 100R1-04 | 1SN-04 | 6.4 | 1/4" | 6.2-7.0 | 14. 1MAX . | 225 | 3263 | 900 | 13050 | 100 | 0.255 | 50/100 | ××××1-××-04 | 00110-04 |

| SAE 100R1-05 | 1SN-05 | 7.9 | 5/16" | 7.7-8.5 | 15.7 MAX . | 215 | 3118 | 860 | 12470 | 115 | 0.304 | 50/100 | ××××1-××-05 | 00110-05 |

| SAE 100R1-06 | 1SN-06 | 9.5 | 3/8" | 9.3-10.1 | 18.1 MAX . | 180 | 2610 | 720 | 10440 | 130 | 0.390 | 50/100 | ××××1-××-06 | 00110-06 |

| SAE 100R1-08 | 1SN-08 | 12.7 | 1/2" | 12.3-13.5 | 21.4 MAX . | 160 | 2320 | 640 | 9280 | 180 | 0.472 | 50/100 | ××××1-××-08 | 00110-08 |

| SAE 100R1-10 | 1SN-10 | 15.9 | 5/8" | 15.5-16.7 | 24.5 MAX . | 130 | 1885 | 520 | 7540 | 205 | 0.581 | 50/100 | ××××1-××-10 | 00110-10 |

| SAE 100R1-12 | 1SN-12 | 19.1 | 3/4" | 18.6-19.8 | 28.5 MAX . | 105 | 1523 | 420 | 6090 | 240 | 0.690 | 50/100 | ××××1-××-12 | 00110-12 |

| SAE 100R1-16 | 1SN-16 | 25.4 | 1" | 25.0-26.4 | 36.6 MAX . | 87 | 1262 | 348 | 5046 | 300 | 0.830 | 50/100 | ××××1-××-16 | 00110-16 |

| SAE 100R1-20 | 1SN-20 | 31.8 | 1.1/4" | 31.4-33.0 | 44.8 MAX . | 63 | 914 | 252 | 3654 | 420 | 1.325 | 20/40 | ××××1-××-20 | 00110-20 |

| SAE 100R1-24 | 1SN-24 | 38.1 | 1.1/2" | 37.7-39.3 | 52.1 MAX . | 50 | 725 | 200 | 2900 | 500 | 1.500 | 20/40 | ××××1-××-24 | 00110-24 |

| SAE 100R1-32 | 1SN-32 | 50.8 | 2" | 50.4-52.0 | 65.5 MAX . | 40 | 580 | 160 | 2320 | 630 | 1.875 | 20/40 | ××××1-××-32 | 00110-32 |

Double-Wire Braided Hydraulic Hose

Double wire braid hydraulic hose construction: It is made of synthetic rubber lining of oil resistant, two wire braid reinforcement separated by synthetic rubber layer, and synthetic rubber cover that is oil, fuel, weather and abrasion resistant.

Low & medium pressure hydraulic systems, petroleum & water-based fluids, Construction equipment, Agriculture equipment

- Reinforcement: 2 Wire Steel Braid

- Outer Cover: MSHA Certified, Vulcanized Abrasion and Weather Resistant Synthetic Rubber

- Temp Operating Range: -40°F/-40°C to 212°F/100°C (+248°F/120°C max.)

EN 853-2SN double steel wire braided Hydraulic Hose

EN857 2SC double steel wire braided Hydraulic Hose

SAE 100R16 double steel wire braided Hydraulic Hose

SAE 100R17 double steel wire braided two wire Hydraulic Hose

SAE 100R2 Double Steel Wire Braided Hydraulic Rubber Hose Technical Specification

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m | Codigo | Codigo |

| SAE 100R2-03 | 2SN-03 | 4.8 | 3/16" | 4.6-5.4 | 14.1 MAX . | 415 | 6018 | 1660 | 24070 | 90 | 0.340 | 50/100 | ××××1-××-03 | 00210-03 |

| SAE 100R2-04 | 2SN-04 | 6.4 | 1/4" | 6.2-7.0 | 15.7 MAX . | 400 | 5800 | 1600 | 23200 | 100 | 0.372 | 50/100 | ××××1-××-04 | 00210-04 |

| SAE 100R2-05 | 2SN-05 | 7.9 | 5/16" | 7.7-8.5 | 17.3 MAX . | 350 | 5075 | 1400 | 20300 | 115 | 0.430 | 50/100 | ××××1-××-05 | 00210-05 |

| SAE 100R2-06 | 2SN-06 | 9.5 | 3/8" | 9.3-10.1 | 19.7 MAX . | 330 | 4785 | 1320 | 19140 | 125 | 0.560 | 50/100 | ××××1-××-06 | 00210-06 |

| SAE 100R2-08 | 2SN-08 | 12.7 | 1/2" | 12.3-13.5 | 23.0 MAX . | 275 | 3988 | 1100 | 15950 | 180 | 0.640 | 50/100 | ××××1-××-08 | 00210-08 |

| SAE 100R2-10 | 2SN-10 | 15.9 | 5/8" | 15.5-16.7 | 26.2 MAX . | 250 | 3625 | 1000 | 14500 | 205 | 0.732 | 50/100 | ××××1-××-10 | 00210-10 |

| SAE 100R2-12 | 2SN-12 | 19.1 | 3/4" | 18.6-19.8 | 30.1 MAX . | 215 | 3118 | 860 | 12470 | 240 | 0.930 | 50/100 | ××××1-××-12 | 00210-12 |

| SAE 100R2-16 | 2SN-16 | 25.4 | 1" | 25.0-26.4 | 38.9 MAX . | 165 | 2393 | 660 | 9570 | 300 | 1.360 | 50/100 | ××××1-××-16 | 00210-16 |

| SAE 100R2-20 | 2SN-20 | 31.8 | 1.1/4" | 31.4-33.0 | 49.5 MAX . | 125 | 1813 | 500 | 7250 | 420 | 1.850 | 20/40 | ××××1-××-20 | 00210-20 |

| SAE 100R2-24 | 2SN-24 | 38.1 | 1.1/2" | 37.7-39.3 | 55.9 MAX . | 90 | 1305 | 360 | 5220 | 500 | 2.300 | 20/40 | ××××1-××-24 | 00210-24 |

| SAE 100R2-32 | 2SN-32 | 50.8 | 2" | 50.4-52.0 | 68.6 MAX . | 80 | 1160 | 320 | 4640 | 630 | 2.650 | 20/40 | ××××1-××-32 | 00210-32 |

SAE 100R17 one or two steel wire braided hydraulic hose

3000 psi constant pressure hose that exceeds with impulse life, temperatures and abrasion resistance all exceeding the industry standards. This provides more durability and longer life hose assemblies. Recommended for high-pressure oil lines used on construction equipment and other off-highway applications

Steel wire braided hoses can be used to transport petrochemicals and hydraulic fluids under relatively high pressures and temperatures. In addition, oil-resistant wire braided hoses can provide flexible connections between steel pipes in hydraulic systems. They can find their applications in the fields of mine hydraulic bracket, automatic hydraulic systems of oil field exploiting machine, mine projects and other industrial sectors, especially used as jackhammer component. It can withstand in the temperature of -40°C to +100°C, and the maximum temperature can be +125°C. Also the surface of steel wire braided hydraulic hose can be two types including smooth and fabric surface.

Stainless Steel Braided PTFE Hoses

The Stainless Steel PTFE Hose merges a white extruded PTFE inner core with a stainless-steel braid outer cover, assuring superior chemical resistance and thermal stability from -65°F to 450°F. Ideally suited for the chemical, pharmaceutical, and food processing industries where hoses encounter high temperatures and corrosive substances.

SAE 100R14 Stainless Steel Braided PTFE Hydraulic Hoses Technical Specification

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | ||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm |

| SNP-R1401 | R14-01 | 3.2 | 1/8" | 3.0-3.4 | 5.8-6.2 | 280 | 4060 | 840 | 12180 | 40 |

| SNP-R1402 | R14-02 | 4.8 | 3/16" | 4.6-5.0 | 7.6-8.2 | 233 | 3379 | 699 | 10135.5 | 50 |

| SNP-R1403 | R14-03 | 6.4 | 1/4" | 6.1-6.5 | 9.1-9.7 | 210 | 3045 | 630 | 9135 | 75 |

| SNP-R1404 | R14-04 | 7.9 | 5/16" | 7.9-8.3 | 10.9-11.5 | 187 | 2712 | 561 | 8134.5 | 100 |

| SNP-R1405 | R14-05 | 9.5 | 3/8" | 9.5-10 | 12.6-13.2 | 163 | 2364 | 489 | 7090.5 | 125 |

| SNP-R1406 | R14-06 | 10.5 | 13/32" | 10.0-10.5 | 12.9-13.5 | 150 | 2175 | 450 | 6525 | 165 |

| SNP-R1407 | R14-07 | 12.7 | 1/2" | 12.7-13.2 | 15.6-16.2 | 140 | 2030 | 420 | 6090 | 165 |

| SNP-R1408 | R14-08 | 15.9 | 5/8" | 15.8-16.3 | 18.9-19.5 | 117 | 1697 | 351 | 5089.5 | 200 |

| SNP-R1409 | R14-09 | 19.1 | 3/4" | 18.8-19.3 | 22.9-23.5 | 93 | 1349 | 279 | 4045.5 | 230 |

| SNP-R1410 | R14-10 | 22.0 | 7/8" | 21.8-22.3 | 26.2-26.8 | 82 | 1189 | 246 | 3567 | 260 |

| SNP-R1411 | R14-11 | 25.4 | 1" | 24.8-25.3 | 28.9-29.5 | 58 | 841 | 174 | 2523 | 300 |

Sinopulse has the largest inventory of steel wire braided hydraulic hose in the China. Our braided hydraulic hose is designed for medium to high-pressure applications and is constructed of the highest quality materials. With oil-resistant synthetic rubber inner cores, high tensile steel wire braiding, and abrasion, weather, and ozone resistant synthetic rubber outer covers, Sinopulse braided hydraulic hose is ideal for nearly any hydraulic application.

Do you need bulk custom steel wire braided hydraulic hose? Contact us, and we will create your custom steel wire braided hydraulic hose to keep your equipment running for every industry.

Why You Should Replace Rubber Hoses with Braided Steel Wire Hoses

Hoses are an integral part of your home plumbing equipment, but not all hoses are created equal.

If your appliances come with rubber hoses, it’s time to consider upgrading them to braided steel hoses.

Here are some of the top reasons to replace the rubber hoses on these appliances.

Braided Steel Hoses Last Longer

It’s more convenient to use braided steel hoses than rubber hoses, which are sensitive to heat, water, and chemicals. These factors can cause leaks or ruptures, which can lead to flooding and water damage. However, steel hoses are sturdier and can withstand greater wear and tear, such as higher water pressure.

Braided Steel Hoses Are Safer

Since steel hoses are less likely to break

Braided Steel Hoses Don’t Bend

Rubber hoses bend easily, which can impede water flow, and steel hoses are tough and won’t kink or bend like rubber hoses.

While braided steel hoses last longer, you still need to plan to replace them within three to five years. Although steel hoses are much less likely to kink or leak, you should still check them once or twice a year to make sure there is no damage.

Braided Hydraulic Hose vs. Spiral Hose: Which to Use?

Braided Hydraulic Hose

Wire braided hydraulic hose consists of one or two high-strength steel wires that are braided and overlapped in a crisscross pattern around a synthetic rubber or elastomeric hose. The braiding of the wires is done on a machine that wraps the wires around the hose in a crisscross pattern. This overlapping braiding provides flexibility, allows for tight bends, and significantly improves burst resistance. Unlike spiral-wound hose, braided hydraulic hose can withstand greater tensile stress, allowing for tighter bend radii.

Braided hose is the most popular hydraulic hose, primarily due to its superior strength and flexibility. While available in a variety of pressure ratings and sizes, the pressure rating decreases as the ID of the inner tube increases. This equates to a four-to-one safety factor for the hose, with a working pressure of one-quarter the burst pressure.

Spiral Hydraulic Hose

Spiral hydraulic hose is stiffer and is typically used in high-pressure applications where there are no significant space constraints and the hose does not need to be extremely flexible. Spiral-wound hose consists of four or six steel wires, depending on the application, that are wound in a spiral and stacked on top of each other, rather than being wound like a braided hose. Spiral hose uses high-tensile steel wire to provide excellent strength to hydraulic hoses, but it is also very inflexible and has a minimal bend radius. However, the smaller the diameter, the smaller the bend radius.

For example, a small diameter spiral wound hydraulic hose only needs one layer of spiral wire to operate at 3000 PSI, so it is inherently flexible. Whereas a large diameter hose may need four layers of spiral wire to withstand 3000 PSI, which will make it very rigid and have a greatly reduced bend radius, resulting in less routing flexibility.

Spiral hydraulic hose has extremely high resistance to pressure spikes, which is necessary for many large diameter, high pressure applications.

Braided vs. Spiral: Which to Choose

It really comes down to trade-offs. If the application requires a high pressure hose that can withstand higher pulses, then a spiral wound hose is the best choice. But you will sacrifice flexibility and it will be difficult to build a system in a small space or connect to equipment that frequently articulates, such as a backhoe or robotic arm. In these applications, a braided hose may be the best choice. In fact, according to the technical brief: “Robotic system designers should choose the right power source for the job. Often, electric motors are chosen without considering the advantages of hydraulics or pneumatics. For applications that require precise control of large forces and smooth motion, or applications that require motion to be “forgiving,” fluid power can provide significant advantages over electromechanical motion.”

For example, using the same hose construction type in a braided hose and then in a spiral-wound hose, flexibility decreases as the diameter increases.

Braided hoses are used in low to medium pressure, lower pressure applications such as engines, hydraulic lifts, and return lines. Spiral hoses are best suited for high pressures and frequent pressure fluctuations such as hydrostatic drives, large off-road earthmoving dump trucks, or mining excavators. In short, braided hoses are great for high pressure applications that require a tight bend radius, while spiral hoses are best suited for extremely high pressure, high pulse applications.

Braided Steel Hoses Manufacturing Process