Food Grade Suction and Discharge Hose

Food and beverage hoses are designed for the safe transfer of liquids, solids and gases in food and beverage processing applications. Designed to meet industry standards, these hoses are made from materials that ensure cleanliness, flexibility, and odor and contamination resistance. Ideally suited for breweries, dairies, distilleries and food processing facilities, these hoses provide durability and reliable performance while maintaining product integrity. Whether pumping, draining or conveying, food and beverage hoses help ensure efficient, sanitary operations.

Food-grade EPDM tubing is odorless and tasteless for non-oily transfer applications. Ultra-flexible, anti-microbial, food-grade suction and discharge hoses are designed for beer, wine, drinking water, grain, powders, flour, dry food, oil, syrup, dairy, juice, and more. Hoses meet FDA, USDA, 3-A Sanitary Standard Authorization (#1376), and CFIA.

What Is a Food Grade Hose?

Food grade hose (or food grade tube) is used for the transfer and transportation of food products such as seeds, pellets, beer and water. They are used in a variety of applications to prevent product contamination

What Are Food Grade Hoses?

Food Grade Hoses are flexible tubing specifically designed to handle the movement of dry bulk food materials in a sanitary and contamination-free manner. According to the FDA (Food and Drug Administration), food grade hoses must adhere to strict, specific guidelines to avoid spoilage and potential contamination during everyday use. Contamination that may affect the quality, flavor, aroma and overall purity of food products may pose a health risk to consumers and, if quality is not up to par, can lead to regulatory violations and devastating lawsuits.

For this reason, agricultural facilities and farms must use FDA-approved hoses to ensure the safe transportation and production of food. This includes the use of translucent and white flexible hoses, as translucent food-grade tubing will allow operators and inspectors to detect clogs, blockages and possible contamination. Meanwhile, white tubing is made of higher purity plastics, indicating that they do not contain any dyes or recycled materials.

Another important factor in facility inspections is whether the food-grade hose is designed for its specific application, as some applications that require alcohol or acid resistance require durable, chemical-resistant, flexible piping to ensure that certain plastic materials don't leak into the process as the product is moved from one place to another.

By following these standards and regulations, food processing facilities will be able to rely on flexible piping designs that are common throughout the industry and won't have to worry about whether or not they're using non-compliant food-grade piping.

What Is Considered a Food Grade Hose?

For a flexible hose to be considered a food grade hose, it must meet the standards and specifications set by the FDA. For a material to be an FDA hose, this must mean that the material must be durable enough not to undergo any physical changes when exposed to temperature, must not leach any chemicals onto food, and must be able to pass through rigorous cleaning and sanitizing cycles. With this in mind, food-grade hose must be made from non-toxic materials such as PVC, thermoplastic rubber, and polyurethane, as plastics and rubber are inherently resistant to chemicals, moisture, and extreme temperatures.

FDA-approved hose must also have excellent durability and pressure-carrying capacity to handle all the daily rigors of food processing and transfer. Most importantly, however, all food-grade hoses must be designed to be odorless and tasteless to ensure that the integrity of the food material is preserved and transferred in its most natural state. By adhering to these rules and regulations, food manufacturers can appropriately utilize the right food-grade hose for their specific application.

Should FDA hose be static dissipative?

FDA hose should be static dissipative if the material being conveyed is inherently flammable and abrasive. When food-grade hose conveys large quantities of dry foods and grains, the abrasive nature of the dry material can create a static buildup. Static dissipative flexible hose is designed to allow static energy to be discharged and escape through the flexible hose wall.

If the flexible hose does not dissipate any charge, it can create a spark that sends an energy current to the machine's central system or ignite the material and cause massive fires and explosions. Considering how much flammable material surrounds most agricultural facilities, a static-related explosion could destroy the facility and the workers inside. With this in mind, there is a reason why agricultural processing plants such as grain handling facilities take as many precautions as possible to control the flow of grain dust.

If an electrical spark were to develop in a flexible duct throughout the facility, it could ignite the grain dust and cause a massive accident. For this reason, agricultural facilities must reduce the likelihood of static-related incidents by using food-grade static dissipative hoses and eliminating as many ignition sources and exposures as possible.

What Makes a Hose Food Safe?

In order to be approved for use, food quality hoses must meet several criteria. One of the most common problems is that they must be approved by the FDA. The FDA sets standards that must be met for materials used in hoses, such as plasticizers.

Another common criterion is that the materials must meet the EN No 10/2011 standard for food contact applications. Similarly, food-safe water hoses must be approved by NSF 51 + NSF 61 before they can be used to convey drinking water.

Is PVC Food Safe?

PVC can be food safe. However, it must meet many criteria to be considered so. Standard PVC may contain substances such as phthalates (a synthetic chemical used in hose manufacturing) that can leach out of the hose and into the product it conveys.

PVC is one of the most common materials used to make food-grade hose. PVC tends to be odorless and tasteless, which makes it an ideal material, unlike other hose materials that can transfer odors or flavors into the product.

Which PVC Hose is FDA Approved?

While PVC hose is used in a variety of applications such as moving air, dust and fumes, clear-colored PVC hose is an FDA-approved hose that is a viable and cost-effective choice for any food-grade piping. Similar to polyurethane flexible hose, PVC flexible ducting is available in different weight classes: light, medium and heavy duty.

Each PVC flexible hose is reinforced with coiled spring steel wire and has an operating temperature range of -20 to +160 degrees Fahrenheit, making it ideal for a variety of applications involving food processing, pharmaceutical and healthcare applications. These flexible hoses also offer excellent abrasion, chemical and moisture resistance, which makes them especially good as food-grade hoses.

In addition, the clear, translucent color allows operators to spot any clogs or blockages as they occur, a feature that alone can significantly reduce maintenance downtime and temporary repairs. However, while PVC hose is less flexible than other hoses, such as polyurethane and thermoplastic hose, PVC is a very affordable alternative for those seeking FDA-approved general purpose hose!

What Are the Properties of PVC Food Grade Hoses?

Flexibility - Flexibility is a must for any food grade hose. Most applications require a hose or tube that is flexible and resistant to kinking. Food grade hoses are durable and easy to handle.

Abrasion Resistance - Since food grade hose is often used for solid product transfer, the hose needs to be resistant to abrasion to prevent breakage and leakage. Some of our heavy-duty food-grade hoses contain internal stainless steel spirals to prevent the hose from being crushed or kinked.

Odor Resistance - When dealing with applications that involve the transfer of food and beverages, it's important that the hose or tube doesn't transfer any odors or flavors to the product it's conveying. Standard PVC hose poses a risk of contamination, while food-grade hose made from odor-resistant PVC is ideal.

Chemical Resistance - Food-safe hoses also tend to have higher chemical resistance than standard PVC hoses, which makes them better suited for heavy-duty applications such as food processing plants.

Temperature resistance - Food-safe hoses are also able to withstand high temperatures. ThermoFlex is a high-temperature food-grade hose that can withstand temperatures up to 70 °C, while our suction and discharge food-grade hoses can withstand temperatures as low as -40 °C without losing flexibility.

Pressure resistance - Food grade hose can also withstand higher pressures, unlike standard PVC, which weakens over time.

Why use food-grade hose

Food-grade hoses provide clean, safe transfer of liquids and dry bulk food materials within pneumatic or suction systems. Because they come into contact with food, the hose material must not contain substances that could leach into the food and impair its purity, quality, odor or taste. In addition, these hoses must protect the food from external contaminants during transfer.

Non-metallic construction: In order to eliminate potential contamination caused by metal corrosion, our food-grade hoses are made of non-toxic, non-metallic materials such as PVC or rubber.

PVC or Rubber Materials: Our hoses are specially formulated to withstand the rigors of the food processing environment. This includes exposure to sanitizers, frequent cleaning procedures, harsh operating conditions and high temperatures.

Chemical resistance: Food and beverages can react unfavorably with certain materials, resulting in the production of hazardous chemicals and acids that can compromise product safety and quality. Our food-grade hoses are made from non-toxic materials that resist such reactions.

Odorless and tasteless: In order to maintain the integrity and flavor of food products, our food-grade hoses are made from odorless and tasteless materials. This ensures that the hose will not affect the flavor or quality of the product.

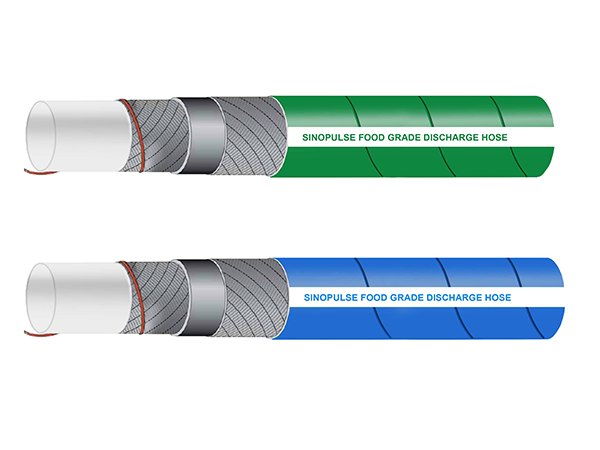

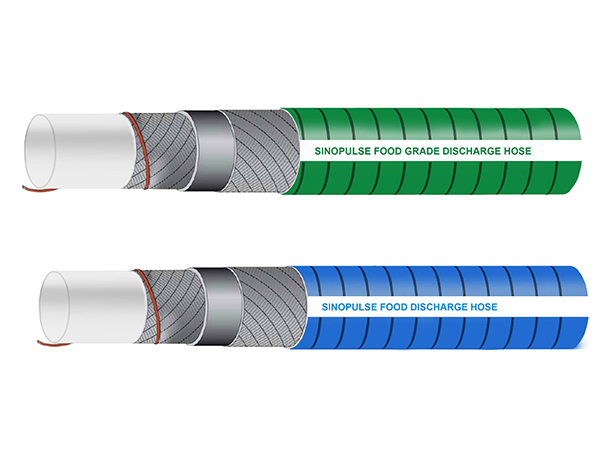

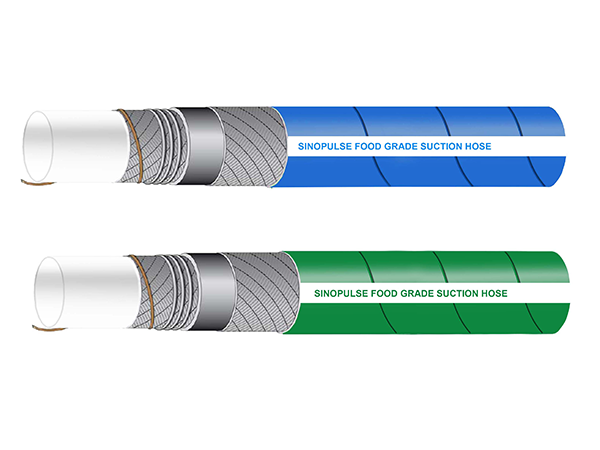

Types of Food-Grade Hoses

There are several types of food-grade hoses, each of which is suitable for certain types of food conveying applications. Selecting the most appropriate hose for an application will depend on a number of factors, including the operating conditions of the application and the characteristics of the food or beverage being conveyed.

Are Garden Hoses Food Safe?

Are garden hoses safe for drinking water? This is a common question and the answer is that garden hoses are not usually considered safe for drinking water unless otherwise stated.

Even after use, garden hoses can still retain water. If the garden hose is also exposed to sunlight, the warmth can cause bacteria to build up inside the hose.

Depending on the manufacturer, cheaper PVC garden hoses may also contain lead, which can cause health problems even in low doses. Cheaper garden hoses may also contain phthalates, which can be transferred to plants, lawns or crops grown in the garden.

When choosing a garden hose, it's important to make sure that it doesn't contain phthalates or DEPH so that any harmful substances can't be transferred from the hose into the garden.

When to choose food grade silicone hose

The equipment and hoses used in food and beverage production do not compromise quality. Instead, hoses must maintain the quality and integrity of the ingredients being processed. Silicone hoses are a good choice because they are relatively inert. They hold up well at both high and low temperatures and do not adhere to the material passing through them, allowing them to maintain the high quality of the final product.

Some hose materials may bleed into the component being processed, but silicone hoses do not. They are ideal for the food and beverage industry because they are inert in many environments and under many different conditions.

These are just a few of the applications and locations that benefit from using inert silicone hoses that hold up well without degrading or breaking down into the ingredients being processed:

Breweries

wineries

Dispensing of food grade products

Beverage dispensers

Water treatment and distribution plants

Juice and other beverage manufacturers

Filtration Systems

Another important consideration when processing food and beverages is the ability to maintain the nutritional value of the product. Silicone hoses accomplish this by protecting the ingredients flowing through them from degradation. Due to their relative inertness, silicone hoses do not alter the presence of vitamins and minerals in food because the tubing material does not interact with the contents flowing through these hoses.

Silicone hoses form a hermetic barrier to the outside world, which means that contaminants cannot accidentally enter a properly designed and properly constructed food or beverage processing system. Silicone materials are not inherently porous, so external contaminants can be kept away from the processing stream.

Safety must come first when manufacturing, handling or processing consumer products. There is no room for error in this department! You must ensure that the substances you produce or handle will not harm anyone in any way. Because silicone hoses are inert, form an effective barrier against temperature fluctuations, and can safely come into direct contact with food and beverages without contaminating them, they are an excellent choice for maintaining a high level of consumer safety.

When to Choose Food-Grade Plastic Tubing

Do you need FDA-approved PVC for the piping in your beverage dispensing tower? Do you need food-grade polyethylene for your commercial kitchen? Need some safe drinking water tubing? Offering a wide selection of high-performance food-safe tubing, you can meet all your food and beverage tubing needs.

Food and Beverage Dispensing Equipment - Flexibility, chemical resistance, FDA and NSF compliance, and high performance are some of the factors to consider when dispensing food and beverage tubing.

Beer and Wine Dispensing - Ideal for soda, beer, juice and spirits.

Air Line Dispensing - Many manufacturing facilities require their air lines to be FDA compliant. Depending on your working pressures and temperatures, Sinopulse offers FDA-compliant products to meet your air line needs!

When to Choose Thermoplastic Food-Grade Hoses

Thermoplastic hoses are made from heat and chemical resistant flexible plastic polymer materials. These hoses are suitable for the transfer and processing of a wide variety of liquid food products including juices, beer, wine, water, pastes and syrups.

When to Choose Rubber Food-Grade Hoses

The durability of food-grade rubber hoses makes them ideal for demanding, heavy-duty food transfer applications. Like thermoplastic hoses, rubber hoses are designed for suction and discharge of a wide variety of liquid foods and edible grains. Manufactured to all FDA food-grade standards and featuring a helical steel wire reinforcement that allows it to be grounded. These products include:

FDA Bulk Food Suction Hose: White natural rubber hose for suction, pneumatic or gravity transfer of edible grains and powders. Built-in spiral steel wire provides proper grounding when attached directly to the end of the hose.

FDA Liquid Food Suction Hose: This white nitrile rubber hose is designed for suction and discharge of liquid foods.

When to Choose Polyethylene Food Safe Tubing

Polyethylene food and beverage tubing is a cost-effective option that brings flexibility, crack resistance and many other benefits to any application. Made from linear low-density polyethylene (LLDPE), this food-grade tubing features high burst pressure, high tensile strength, and is tasteless and odorless. Polyethylene is well suited for food and beverage processing systems that use push-on or compression fittings.

When to Choose UHMWPE Food Grade Hose

UHMWPE (Ultra High Molecular Weight Polyethylene) hose is specifically designed and formulated to transport up to 96% alcohol, wine, beer, drinking water, and other related foods. This FDA-approved hose is versatile. With the ability to handle up to 96% alcohol, these hoses are ideal for breweries, wineries and distilleries. The hose is made of clear UHMWPE tubing to ensure food quality.

The hose is odorless and does not alter the flavor of the product. These hoses have a high working temperature and can be easily steam sterilized at 230ºF for 30 minutes. They comply with FDA Part 21, Section 177.2600(e) for liquid foods, are BfR-free, ADI-free, and comply with EC 1935 / 2004 Order this hose for your brewery, winery, or distillery today!

When to Choose EPDM Food Suction & Discharge Hose

Rubber hose recommended for food transfer applications requiring flexibility and ruggedness in a clean white FDA-rated tube. Food grade EPDM hose is odorless and tasteless for non-oil transfer applications. Ideal for inhalation and discharge applications. This ultra-smooth, anti-microbial tube is made with a special stainless steel mandrel to ensure cleanliness.

What are the Required Regulations for Food Grade Hose?

food-grade tubing must meet strict standards for safe use, including FDA guidelines for the regulatory compliance of plastic materials used with food equipment or food contact applications. In the past, we’ve supplied food-safe tubing that is compliant with many regulatory statutes, including:

USPVI

NSFSI

REACH

RoHS

NSF61

NSF51

Phthalate-free requirements

And others!

We produce top quality food & beverage transfer hoses our own factory, Sinopulse food grade hoses for handling in-plant and/or tank truck transfer of beer, wine, cider, spirits, potable water and other non-oily, liquid food products. These food grade flexible hoses are easy to clean! We have several options depending on your budget and requirements. The corrugated cover is chemical, oil, and abrasion resistant. Custom liquid transfer hose lengths are also available.

Sinopulse manufactures and supply superior-quality food-grade hoses for the safe and aseptic transfer of food products. All of our hoses are designed to meet the appropriate FDA, USDA and 3A requirements, and many are also available in full vacuum ratings. Our portfolio includes a wide range of specialized hose options, as well as accessories and attachments to support their use. Provide safe and food-safe transfer solutions to maintain the quality and integrity of your products.