Hydraulic Hose Protection Sleeve

Hose Protective Sleeve / Hydraulic Hose Protection

Hydraulic and pneumatic hose lines are often subjected to harsh conditions, whether you're underground mining or tilling fields we have a suitable sleeve to protect your uptime!

The Hose Protection Sleeve extends the life of your hydraulic and pneumatic hoses, avoiding downtime, oil loss, contamination, and unnecessary expenses for hose replacement.

Each Hose Protection Sleeve wraps around one hose or hose bundle to keep contaminants out and protect them in the harshest working environments.

The Hose Protection Sleeve is suitable for any environment in nearly any machine, including industrial machinery, ocean-going vessels, and heavy equipment. Stop replacing hoses and start protecting them from abrasion, UV rays, wind, rain, snow, and dry rot. If you have a hose, the Hose Protection Sleeve has it covered.

Sinopulse Hose Protection

At Sinopulse, we offer complete hydraulic hose protection for your hydraulic system. We offer hose protective products include:

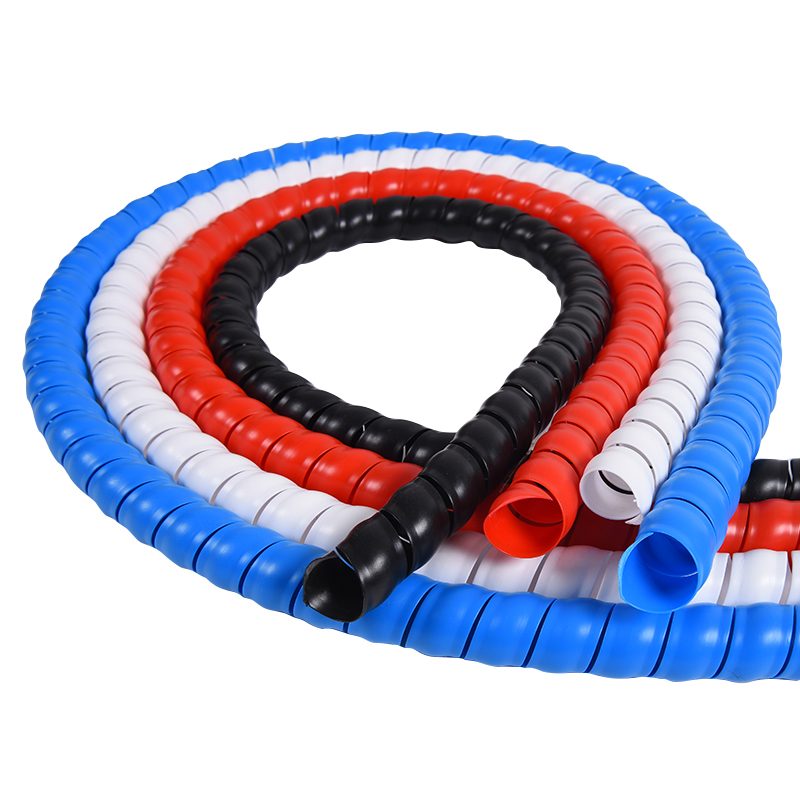

Spiral Guard

Nylon Sleeve

Wire Armour

Fire Sleeve (260°C rated)

All these products feature very durable construction. They are made from our own factroy and are available in many different sizes. We have a comprehensive variety of hydraulic hose protection wraps and guards to protect your hose connectors and high-pressure hoses against heat, abrasives, and punctures.

Flexible nylon sleeve protects hose from abrasion and allows bundling of hose lines.

Rust-resistant steel wire protects hose cover from abrasion and accidental damage

UV-resistant plastic coil protects ...

Spiral Guard Wrap protects against abrasion, cuts, crushing, UV and various hazards.

Made of heat and chemical resistant material and adjustable to fit various hose sizes

Nylon Sleeve Hose Guard | Nylon Protection Sleeving

Construction:

High tenacity multi-filament nylon

Application:Nylon protective sleeve is mainly used for wear resistance and

explosion proof hydraulic hose, oil rubber hose, the trachea and other pipe

fitting. Especially suitable for work at the severe condition.

TEMPERATURE: -50°C to- 190°C

| Code | Inside Diameter (mm) | Flat Width(mm) | Wall Thickness(mm) | Length(M) |

| NPS-020 | 20 | 12 | 1 | 50 |

| NPS-025 | 25 | 15 | 1 | 50 |

| NPS-030 | 30 | 17 | 1 | 50 |

| NPS-035 | 35 | 20 | 1 | 50 |

| NPS-040 | 40 | 23 | 1 | 50 |

| NPS-045 | 45 | 26 | 1 | 50 |

| NPS-050 | 50 | 31 | 1 | 50 |

| NPS-060 | 60 | 37 | 1 | 50 |

| NPS-070 | 70 | 44 | 1 | 50 |

| NPS-080 | 80 | 50 | 1 | 50 |

| NPS-090 | 90 | 56 | 1 | 50 |

| NPS-100 | 100 | 62 | 1 | 50 |

| NPS-115 | 115 | 72 | 1 | 50 |

| NPS-145 | 145 | 90 | 1 | 50 |

| NPS-176 | 176 | 110 | 1 | 50 |

Plastic Spiral Hose Wrap | Plastic Spiral Hose Wrap

Construction:

Material:PP (Polypropylene)

Application:Such hose sleeve is economical and convenient to protect the hydraulic and pneumatic hose, cable, wire and rope from premature wear. It can also extend the service life if them. Spiral wrap tubing can bear the extreme climate and work conditions. Spiral Guard Wrap protects against abrasion, cuts, crushing, UV and various hazards. Spiral Guard Wrap’s open spiral design makes it easy to install in the field, without the need to disconnect lines.

TEMPERATURE: -50°C to +80°C

Flat Surface spiral PP hose protective sleeve

| Code | Size | ID (mm) | OD (mm) | Wall Thickness (mm) | Width (mm) |

| FPS008 | 8 | 8 | 10 | 1 | 12 |

| FPS010 | 10 | 10 | 12 | 1 | 12 |

| FPS012 | 12 | 12 | 14 | 1 | 12 |

| FPS014 | 14 | 14 | 16 | 1 | 13 |

| FPS016 | 16 | 16 | 18.8 | 1.4 | 14.5 |

| FPS018 | 18 | 18 | 21.2 | 1.6 | 15.5 |

| FPS019 | 19 | 19 | 22.2 | 1.6 | 15.5 |

| FPS021 | 21 | 21 | 24.6 | 1.8 | 18.5 |

| FPS022 | 22 | 22 | 25.6 | 1.8 | 18.5 |

| FPS025 | 25 | 25 | 28.6 | 1.8 | 21.5 |

| FPS026 | 26 | 26 | 29.6 | 1.8 | 21.5 |

| FPS028 | 28 | 28 | 31.8 | 1.9 | 22.5 |

| FPS030 | 30 | 30 | 34 | 2 | 23 |

| FPS032 | 32 | 32 | 36 | 2 | 23 |

| FPS035 | 35 | 35 | 39 | 2 | 24 |

| FPS038 | 38 | 38 | 42 | 2 | 24 |

| FPS040 | 40 | 40 | 45.6 | 2.8 | 25 |

| FPS042 | 42 | 42 | 48 | 3 | 26 |

| FPS045 | 45 | 45 | 51 | 3 | 27 |

| FPS048 | 48 | 48 | 54 | 3 | 27 |

| FPS050 | 50 | 50 | 56 | 3 | 27 |

| FPS051 | 51 | 51 | 57 | 3 | 27 |

| FPS060 | 60 | 60 | 66 | 3 | 26.5 |

| FPS063 | 63 | 63 | 69 | 3 | 27 |

| FPS068 | 68 | 68 | 74 | 3 | 30 |

| FPS074 | 74 | 74 | 84.4 | 5.2 | 47.5 |

| FPS080 | 80 | 80 | 89 | 4.5 | 40.5 |

| FPS088 | 88 | 88 | 98 | 5 | 43 |

| FPS100 | 100 | 100 | 110 | 5 | 45 |

Arc Surface spiral PP hose protective sleeve

| Code | Size | ID (mm) | OD (mm) | Wall Thickness (mm) | Width (mm) |

| APS008 | 8 | 8 | 11 | 1.5 | 10 |

| APS010 | 10 | 10 | 12.8 | 1.4 | 11 |

| APS012 | 12 | 12 | 15 | 1.5 | 12 |

| APS014 | 14 | 14 | 17 | 1.5 | 13 |

| APS016 | 16 | 16 | 19.6 | 1.8 | 15 |

| APS018 | 18 | 18 | 21.6 | 1.8 | 16 |

| APS020 | 20 | 20 | 24 | 2 | 18 |

| APS021 | 21 | 21 | 25 | 2 | 18 |

| APS022 | 22 | 22 | 26 | 2 | 18 |

| APS023 | 23 | 23 | 27 | 2 | 19.2 |

| APS024 | 24 | 24 | 28 | 2 | 21 |

| APS025 | 25 | 25 | 29.8 | 2.4 | 21.5 |

| APS028 | 28 | 28 | 33.2 | 2.6 | 23 |

| APS030 | 30 | 30 | 34.8 | 2.4 | 22.5 |

| APS032 | 32 | 32 | 37.6 | 2.8 | 23 |

| APS035 | 35 | 35 | 40.6 | 2.8 | 24 |

| APS038 | 38 | 38 | 44 | 3 | 25 |

| APS040 | 40 | 40 | 47 | 3.5 | 27 |

| APS042 | 42 | 42 | 49 | 3.5 | 25 |

| APS045 | 45 | 45 | 53 | 4 | 28 |

| APS048 | 48 | 48 | 56 | 4 | 28 |

| APS050 | 50 | 50 | 59 | 4.5 | 29 |

| APS052 | 52 | 52 | 61 | 4.5 | 29 |

| APS055 | 55 | 55 | 64 | 4.5 | 30 |

| APS060 | 60 | 60 | 69 | 4.5 | 30 |

| APS063 | 63 | 63 | 72 | 4.5 | 30 |

| APS065 | 65 | 65 | 74 | 4.5 | 30 |

| APS067 | 67 | 67 | 76 | 4.5 | 30 |

| APS070 | 70 | 70 | 79 | 4.5 | 34 |

| APS074 | 74 | 74 | 84 | 5 | 34 |

| APS075 | 75 | 75 | 85 | 5 | 42 |

| APS080 | 80 | 80 | 91 | 5.5 | 45 |

| APS088 | 88 | 88 | 99 | 5.5 | 45 |

| APS090 | 90 | 90 | 101 | 5.5 | 45 |

| APS100 | 100 | 100 | 112 | 6 | 50 |

| APS150 | 150 | 150 | 162 | 6 | 38 |

| APS200 | 200 | 200 | 210 | 5 | 50 |

Hot Products

What is hydraulic hose sleeve?

Hydraulic hose sleeve is a protective covering that shields hydraulic hoses from abrasion, heat, chemicals, and mechanical damage. It helps organize and bundle hoses while extending their service life, enhancing system safety, and ensuring reliable performance in industrial, automotive, construction, and agricultural hydraulic applications.

What is hydraulic hose sleeve advantage?

Sleeves protect hoses from high temperatures, oils, and chemicals, maintaining hose integrity and preventing premature failures in industrial or automotive applications.

Sleeves could provide abrasion protection – Hydraulic hose sleeves shield hoses from rubbing, friction, and mechanical wear, reducing surface damage and extending the operational life of hydraulic systems.

Hydraulic hose sleeves help bundle and organize multiple hoses neatly, simplifying maintenance, reducing tangling, and improving workspace safety and efficiency.

Sleeves can be Easy Installation and Maintenance, providing flexible protection while allowing easy inspection, repair, or replacement of hydraulic hoses when needed.

By protecting hoses from environmental and mechanical stress, sleeves significantly increase service life, reducing replacement frequency and overall maintenance costs.

What is hydraulic hose sleeve made of?

Polyester and Nylon Braids – Braided polyester or nylon sleeves provide excellent abrasion resistance and mechanical strength. We offer these materials to safeguard hoses from friction, bending stress, and wear, maintaining reliable fluid transfer and system safety.

Spiral or Polyethylene Looms – Spiral or split polyethylene looms protect hoses while allowing flexibility and easy installation. We provide these for bundling multiple hydraulic hoses, reducing tangling, abrasion, and mechanical damage during operation.

Neoprene Rubber – Neoprene sleeves offer durability, heat resistance, and chemical protection. We use neoprene to cover hydraulic hoses operating in high-temperature or corrosive environments, ensuring long-term hose integrity and operational safety.

Velcro or Hook-and-Loop Materials – Adjustable Velcro sleeves allow quick installation and removal. We use them to organize and protect hydraulic hoses, simplifying maintenance while preventing wear and improving overall system safety.

Where to use hydraulic hose sleeves

Industrial Machinery – Hydraulic hose sleeves prevent abrasion, chemical corrosion, and heat damage in manufacturing and processing equipment, enhancing operational reliability and minimizing downtime.

Construction Equipment – Sleeves defend hoses in excavators, loaders, and cranes against dirt, debris, and mechanical wear, improving worksite safety and extending the service life of hydraulic systems.

Automotive and Transportation – Hydraulic hose sleeves reduce wear caused by vibration, heat, and friction in trucks, forklifts, and other vehicles, ensuring efficient fluid transfer and durable performance.

Agricultural Machinery – Sleeves shield hoses in tractors, harvesters, and sprayers from harsh environmental conditions, promoting dependable operation and long-term reliability in demanding agricultural settings.

Oil and Gas Industry – Hydraulic hose sleeves offer resistance to abrasion, chemicals, and high temperatures for hoses in pipelines, drilling rigs, and related equipment, contributing to safe and uninterrupted operations.

Marine Applications – Sleeves protect hydraulic hoses from saltwater corrosion, UV radiation, and physical impact, sustaining performance and durability in boats, ships, and offshore installations.

How to Customize Your Desire Hydraulic Hose Sleeve?

Materials: First, you need to choose the appropriate material for your hydraulic hose sleeve. Materials include PVC, polyester, neoprene, and others. You need to select based on its abrasion resistance, heat resistance, chemical corrosion resistance, and adaptability to various environmental conditions. This ensures the hydraulic hose maintains reliable performance under harsh operating conditions.

Length: Accurate sizing ensures a precise fit, complete coverage, and maximum protection while maintaining flexibility and ease of installation for efficient system operation.

Design: Hydraulic hose sleeves come in many designs, including spiral, braided, and split options. Selecting the proper design ensures enhanced abrasion resistance, ease of maintenance, and compatibility with hose routing requirements in diverse applications.

Color Coding and Identification: Using color-coded sleeves helps organize hoses, simplify maintenance, and improve safety by distinguishing lines and fluid types in complex hydraulic systems.