SAE 100R14 Hydraulic Hose

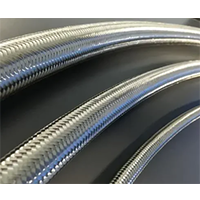

Stainless Steel PTFE Hoses - R14 - SAE100R14

SAE 100 R14 hydraulic hose offers excellent chemical resistance and thermal stability in the -65°F to 450°F range, making R14 hose suitable for transporting petroleum- or water-based hydraulic fluids at operating temperatures from -54°C to +204°C. The hose is available with a stainless steel PTFE core and a braided stainless steel cover. Stainless steel PTFE hose combines a white extruded PTFE core with a stainless steel braided cover, making the hose ideal for chemical, pharmaceutical and food processing industries that encounter high temperatures and corrosive materials.

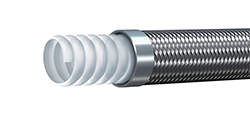

SAE 100R14 hydraulic hose, also known as PTFE (Polytetrafluoroethylene) hose or Teflon hose, is a smoothbore PTFE lined hose. It is made to meet or exceed the SAE 100R14 specification. It could deliver petroleum fluid and water-based hydraulic fluids in the working temperature range of -40°C to +260°C. SAE 100R14 Hose is commonly used in the chemical, pharmaceutical, food processing, and automotive industries. It is designed to handle high temperatures, corrosive fluids, and applications that require a non-stick surface. compare to another hose, it also have the longest life.

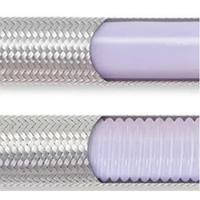

It consists of two layers: a convoluted or smooth PTFE inner tube and a stainless steel braided cover. A smooth PTFE inner tube is ideal for high and low temperature applications, it is also anti-corrosive and non-stick. The braided stainless steel cover is made from SUS304 or SUS316, so it has higher pressure resistance and withstands extreme temperatures. The maximum working pressure can vary depending on the size and construction of the r14 hose, but it is commonly available with pressure ratings up to 3,000 psi.

SAE 100R14 Structure:

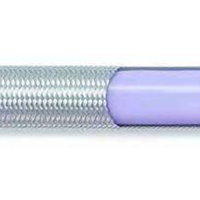

Tube: White Extruded PTFE

Reinforcement: 1-Braid of High Tensile Stainless Steel Wire

Cover:303×× series stainless steel wire; (normal ss316)

Feature

Application: Low pressure and vacuum petroleum base fluid

Safety factor: 4:1

Temperature Range: -40℃ to 260℃(-65°F to 450°F)

Applicable Standards: SAE J517 100R14.

Suitable fitting:SAE 100R14 Range is a smoothbore PTFE lined hose that is made to meet or exceed the SAE 100R14 specification. This range is also available in USA with a fully validated range of fittings and ferrules for your added safety. Use with T-Series Hose Fittings, E Series Crimp Fittings or R14 Reusable Hose Fittings , SAE 100 R14 Ferrule

The specification of the SAE 100 R14 R14 SMOOTH PTFE Tube Hydraulic Hose

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | EsWeightr de pared | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | mm | m | Codigo | Codigo |

| SNP-R14-01 | R14-01 | 3.2 | 1/8" | 3.0-3.4 | 5.8-6.2 | 280 | 4060 PSI | 840 | 12180 | 40 | 1.000 | 90-110 | ××××1-××-02 | 00TFO-02 |

| SNP-R14-02 | R14-02 | 4.8 | 3/16" | 4.6-5.0 | 7.6-8.2 | 233 | 3379 PSI | 699 | 10135.5 | 50 | 1.000 | 90-110 | ××××1-××-03 | 00TFO-03 |

| SNP-R14-03 | R14-03 | 6.4 | 1/4" | 6.1-6.5 | 9.1-9.7 | 210 | 3045 PSI | 630 | 9135 | 75 | 1.000 | 90-110 | ××××1-××-04 | 00TFO-04 |

| SNP-R14-04 | R14-04 | 7.9 | 5/16" | 7.9-8.3 | 10.9-11.5 | 187 | 2712 PSI | 561 | 8134.5 | 100 | 1.000 | 90-110 | ××××1-××-05 | 00TFO-05 |

| SNP-R14-05 | R14-05 | 9.5 | 3/8" | 9.5-10 | 12.6-13.2 | 163 | 2364 PSI | 489 | 7090.5 | 125 | 1.000 | 90-110 | ××××1-××-06 | 00TFO-06 |

| SNP-R14-06 | R14-06 | 10.5 | 13/32" | 10.0-10.5 | 12.9-13.5 | 150 | 2175 PSI | 450 | 6525 | 165 | 1.000 | 90-110 | ××××1-××-08 | 00TFO-08 |

| SNP-R14-07 | R14-07 | 12.7 | 1/2" | 12.7-13.2 | 15.6-16.2 | 140 | 2030 PSI | 420 | 6090 | 165 | 1.000 | 90-110 | ××××1-××-08 | 00TFO-08 |

| SNP-R14-08 | R14-08 | 15.9 | 5/8" | 15.8-16.3 | 18.9-19.5 | 117 | 1697 PSI | 351 | 5089.5 | 200 | 1.000 | 45-55 | ××××1-××-10 | 00TFO-10 |

| SNP-R14-09 | R14-09 | 19.1 | 3/4" | 18.8-19.3 | 22.9-23.5 | 93 | 1349 PSI | 279 | 4045.5 | 230 | 1.500 | 45-55 | ××××1-××-12 | 00TFO-12 |

| SNP-R14-10 | R14-10 | 22.0 | 7/8" | 21.8-22.3 | 26.2-26.8 | 82 | 1189 PSI | 246 | 3567 | 260 | 1.500 | 45-55 | ××××1-××-16 | 00TFO-16 |

| SNP-R14-11 | R14-11 | 25.4 | 1" | 24.8-25.3 | 28.9-29.5 | 58 | 841 PSI | 174 | 2523 | 300 | 1.500 | 45-55 | ××××1-××-20 | 00TFO-20 |

The specification of the SAE 100 R14 R14 Corrugated PTFE Tube Hydraulic Hose

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | EsWeightr de pared | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | mm | m | Codigo | Codigo |

| SNP-R14-C01 | R14C-01 | 3.2 | 1/8" | 3.0-3.8 | 6.3-7.9 | 183 | 2654 PSI | 550 | 7975 | 24 | 1.000 | 45-110 | ××××1-××-02 | 00TFO-02 |

| SNP-R14-C02 | R14C-02 | 4.8 | 3/16" | 5.0-5.6 | 10.2-11.0 | 170 | 2465 PSI | 510 | 7395 | 28 | 1.000 | 45-110 | ××××1-××-03 | 00TFO-03 |

| SNP-R14-C03 | R14C-03 | 6.4 | 1/4" | 6.1-6.8 | 12.3-12.9 | 140 | 2030 PSI | 420 | 6090 | 32 | 1.000 | 45-110 | ××××1-××-04 | 00TFO-04 |

| SNP-R14-C04 | R14C-04 | 7.9 | 5/16" | 7.8-8.5 | 12.5-13.3 | 133 | 1929 PSI | 400 | 5800 | 36 | 1.000 | 45-110 | ××××1-××-05 | 00TFO-05 |

| SNP-R14-C05 | R14C-05 | 9.5 | 3/8" | 9.1-10.2 | 14.0-14.9 | 127 | 1842 PSI | 380 | 5510 | 59 | 1.250 | 45-110 | ××××1-××-06 | 00TFO-06 |

| SNP-R14-C07 | R14C-07 | 12.7 | 1/2" | 13.5-14.5 | 18.2-19.1 | 110 | 1595 PSI | 330 | 4785 | 80 | 1.250 | 45-110 | ××××1-××-08 | 00TFO-08 |

| SNP-R14C08 | R14C-08 | 15.9 | 5/8" | 15.8-17 | 24.2-25.5 | 73 | 1059 PSI | 220 | 3190 | 92 | 1.500 | 45-110 | ××××1-××-08 | 00TFO-08 |

| SNP-R14-C09 | R14C-09 | 19.1 | 3/4" | 19.0-20.2 | 27.8-28.5 | 67 | 972 PSI | 200 | 2900 | 105 | 1.500 | 45-110 | ××××1-××-10 | 00TFO-10 |

| SNP-R14-C10 | R14C-10 | 22.0 | 7/8" | 22.0-23.2 | 30.3-31.5 | 58 | 841 PSI | 175 | 2538 | 120 | 1.500 | 45-110 | ××××1-××-12 | 00TFO-12 |

| SNP-R14-C11 | R14C-11 | 25.4 | 1" | 25.8-26.9 | 34.3-35.5 | 50 | 725 PSI | 150 | 2175 | 135 | 2.000 | 45-110 | ××××1-××-16 | 00TFO-16 |

| SNP-R14-C12 | R14C-12 | 22.0 | 1-1/4" | 38.5-39.9 | 49.8-50.5 | 27 | 392 PSI | 80 | 1160 | 135 | 2.000 | 45-110 | ××××1-××-20 | 00TFO-20 |

| SNP-R14-C13 | R14C-13 | 25.4 | 1-1/2" | 49.5-50.8 | 62.0-63.5 | 19 | 276 PSI | 55 | 798 | 165 | 2.000 | 45-110 | ××××1-××-24 | 00TFO-24 |

Download

Sinopulse Hydraulic Hose Catalog

About Sinopulse hose factory

Raw Material:

Imported rubber material Vietnam and Thailand

High tensile strength 2750Mpa steel wire from China's first-class factory

Powerful, safe and stable hydraulic hose products

Good dispersibility, high bearing pressure and superior pulse performance.

Excellent oil resistance, heat resistance and aging resistance.

Excellent bending resistance and fatigue resistance

Factory Workshop:

Sinopulse is a 100% manufacturer of hydraulic hoses and industrial hoses, including all oilfields, agriculture, transportation, construction, mining, and forestry.

Daily output 500,000 meters of hoses, workshop covering 40,000 m²

40 production lines, involving high-speed joint machines, braiding machines, high-speed spiral machines, Italy VP automatic industrial machines, and Complete series Laboratory Testing Equipment

120 Skilled workers, 6 Engineers with 2 technical counselors from famous international companies,2 QC departments, and 2 warehouse managers are fall of our lovely people.

50 Sales and three groups of logistics specialists serve our clients from Italy, Germany, Uk, Spain, the USA, Canada, Brazil, Argentina, Panama, Peru, Chile, Viet Nam, Indonesia, Australia, Romania

Laboratory:

Our factory introduces a full range of laboratory testing equipment. It has advanced laboratory capabilities to conduct product quality testing and research and development work to ensure stable and excellent product quality.

After purchasing raw materials, we test each batch to ensure they meet our product's technical requirements.

After production, we test each hose, its working and burst pressure, and conduct a pulse test for each order to ensure that it is 100% qualified after leaving the factory.

We strive to provide our customers with top-notch hoses, doing everything we can to ensure their quality.

"Let our end users feel comfortable in use and safe in driving!" is our common goal.

Product packaging:

1. When packing hydraulic hoses, cartons or wooden boxes according to customer requirements.

2. We will pack the hose after finishing the hose production.

3. Generally, woven bags and plastic films are used for packaging.

4. Special packaging can be provided according to customer requirements. Special packaging is a request of Edible ACC Ording customers.

Find a trusted hose factory. Any requirements and problems can ask us at any time.

Hot Products

What is SAE 100R14?

SAE 100R14 PTFE hydraulic hose consists of a polytetrafluoroethylene (PTFE) inner tube and a 303 x x series stainless steel wire braided cover.PTFE tubing is ideal for delivering ultra-high and low-temperature hydraulic fluids in the -65°F to +400°F range. The stainless steel wire braid could make hose resistant to wet conditions, oil, chemicals, abrasion, and all types of weather.

Where are SAE 100R14 hydraulic hoses used

SAE 100R14 PTFE hoses are medium-pressure hydraulic hoses with anon-stick surface. They are widely used in air compressor discharge, hot oils and fluids, hot and greasy environments.

What is R14 Hydraulic Hoses

R14 hoses are PTFE hydraulic hoses with a stainless steel braid cover. The r14 Stainless Steel PTFE Hose has a amooth PTFE inner tube and a stainless-steel braided cover, so it has superior chemical resistance and works excellently in temperatures from -65°F to 450°F. hoses could deliver high temperatures and corrosive substances for the chemical, pharmaceutical, and food processing

What is SAE 100R14 HOSE?

SAE 100 R14 hydraulic hose is suitable for deliver mineral oils, hydraulic fluids, fuel oils, emulsified oils and hydrocarbons. It consists of two parts: the inner tube and the cover. The inner tube is made of smooth PTFE, so it could be resistant to a wide range of hydraulic fluids, corrosion and high and low temperatures. The cover is made of a high-strength stainless steel braid. The hose is resistant to abrasion and highly flexible, could be used in high and low temperature application, it is also anti-corrosive, and non-stick.