EN853 1SN / SAE 100R1AT Hydraulic Hose

SAE 100 R1 Steel Wire Reinforced Hydraulic Hose

SAE 100 R1 hydraulic hose is a single steel wire-braided hydraulic hose. The inner tube and cover are made of synthetic rubber, make it anti-abrasive, resistant to oils, fuels, and atmospheric conditions.

Our R1 hose manufactured to the Society of Automotive Engineers (SAE) Standard for High-Pressure Rubber Hoses for Hydraulic Systems, meets or exceeds the requirements of SAE 100R1AT and EN853 1SN

With up to 2300 PSI working pressure , the R1 hose is suitable for medium pressure application, such as forestry equipment, engineering equipment, etc.

Trust SINOPULSE for your R1 hydraulic hose needs.

According to: ISO 1436 / DIN EN 853 type 1SN / SAE J517 type SAE 100R1 AT

SAE 100 R1AT Hose Structure:

Inner Tube: oil-resistant synthetic rubber.

Reinforcement: 1 braid of high-tensile steel wire.

Cover: weather- and oil-resistant synthetic rubber.

| Hose code | Size | Dash size | Hose I.D. | WD | Hose OD | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | AT | |||||||||

| mm | inch | min | max | min | max | min | max | max | ||

| SAE100R1-01 | 5 | 3/16" | -3 | 4.6 | 5.4 | 8.9 | 10.1 | 11.9 | 13.5 | 12.5 |

| SAE100R1-02 | 6.3 | 1/4" | -4 | 6.2 | 7.0 | 10.6 | 11.7 | 15.1 | 16.7 | 14.1 |

| SAE100R1-03 | 8 | 5/16" | -5 | 7.7 | 8.5 | 12.1 | 13.3 | 16.7 | 18.3 | 15.7 |

| SAE100R1-04 | 10 | 3/8" | -6 | 9.3 | 10.1 | 14.5 | 15.7 | 19.0 | 20.6 | 18.1 |

| SAE100R1-05 | 12.5 | 1/2" | -8 | 12.3 | 13.5 | 17.5 | 19.0 | 22.2 | 23.8 | 21.5 |

| SAE100R1-06 | 16 | 5/8" | -10 | 15.5 | 16.7 | 20.6 | 22.2 | 25.4 | 27.0 | 24.7 |

| SAE100R1-07 | 19 | 3/4" | -12 | 18.6 | 19.8 | 24.6 | 26.2 | 29.4 | 31.0 | 28.6 |

| SAE100R1-08 | 25 | 1" | -16 | 25.0 | 26.4 | 32.5 | 34.1 | 36.9 | 39.3 | 36.6 |

| SAE100R1-09 | 31.5 | 1-1/4" | -20 | 31.4 | 33.0 | 39.3 | 41.7 | 44.4 | 47.6 | 44.8 |

| SAE100R1-10 | 38 | 1-1/2" | -24 | 37.7 | 39.3 | 45.6 | 48.0 | 50.8 | 54.0 | 52.0 |

| SAE100R1-11 | 51 | 2" | -32 | 50.4 | 52.0 | 58.7 | 61.9 | 65.1 | 68.3 | 65.9 |

| Hose code | Working pressure | Proof pressure | Min burst pressure | Min bending radius | Weight | |||

|---|---|---|---|---|---|---|---|---|

| MPa | psi | MPa | psi | MPa | psi | mm | kg/m | |

| SAE100R1-01 | 21.0 | 3045 psi | 42 | 6090 | 84 | 12810 | 90 | 0.210 |

| SAE100R1-02 | 19.2 | 2780 psi | 38.5 | 5580 | 77 | 11165 | 100 | 0.250 |

| SAE100R1-03 | 17.5 | 2540 psi | 35 | 5075 | 70 | 10150 | 115 | 0.311 |

| SAE100R1-04 | 15.7 | 2280 psi | 31.5 | 4570 | 63 | 9135 | 125 | 0.360 |

| SAE100R1-05 | 14.0 | 2030 psi | 28 | 4060 | 56 | 8120 | 180 | 0.451 |

| SAE100R1-06 | 10.5 | 1520 psi | 21 | 3045 | 42 | 6090 | 205 | 0.519 |

| SAE100R1-07 | 8.7 | 1260 psi | 17.5 | 2540 | 35 | 5075 | 240 | 0.651 |

| SAE100R1-08 | 7.0 | 1015 psi | 14 | 2030 | 28 | 4060 | 300 | 0.909 |

| SAE100R1-09 | 4.3 | 620 psi | 8.7 | 1260 | 18 | 2540 | 420 | 1.300 |

| SAE100R1-10 | 3.5 | 510 psi | 7 | 1015 | 14 | 2030 | 500 | 1.690 |

| SAE100R1-11 | 2.6 | 380 psi | 5.2 | 750 | 11 | 1520 | 630 | 2.00 |

Manufacture hoses that meet or exceed SAE 100R1. If you do not find your specified technical data in the table below, please send us your specified technical data.

Sinopulse Brand R1 Hose Layline Example:

SINOPULSE HYDRAULIC HOSE GR1AT-3 SAE 100R1AT 3/16" (DN5) Max. W.P. 21MPa (3045PSI) -2Q11-

Feature

High Quality: Our R1 Hose is made from high-quality synthetic rubber, making the hose resistant to abrasion, corrosion, weather, ozone, aging and anti-kink.

Wide Temperature Range: And the standard SAE 100R1 hose temperature range is from -40℃ to +100℃ (-40°F to 212°F),Intermittent Service 120°C (248°F). If you need a higher temperature R1 hose or a lower temperature R1 hose, please view our high temperature hose series and arctic low temperature hose series, or contact us. We have a professional R&D team to meet your needs.

High working pressure: When you choose 3/16-inch(-03 dash) r1 hose, the maximum working pressure of our r1 hose can reach 3000 psi

Custom Size: We have a variety of inner diameter sizes for you to choose from, range from 3/16" to 2"

Safer: Our R1 hose has been approved by MSHA and ISO 9001. The safety factor of the R1 hose is 4:1, making it much safer.

Applications

Used for conveying low-medium pressure of oil, air or water-based hydraulic fluids.

- Industrial Machinery: SAE 100R1 hoses are commonly used in industrial machinery such as hydraulic presses, machine tools, and conveyor systems. These hoses help transfer hydraulic fluids, operate various components, and ensure smooth, reliable operation.

- Construction Equipment: Hydraulic systems are widely used in construction machinery such as excavators, loaders and cranes, and SAE 100R1 hoses provide the hydraulic power necessary to control the movement of different components such as booms, buckets and outriggers.

- Agricultural Machinery: Tractors, harvesters and other farm equipment rely heavily on hydraulics for functions such as lifting, steering and operating attachments, and SAE 100R1 hose is suitable for transferring hydraulic fluid in these applications.

- Automotive: SAE 100R1 hoses are also used in the automotive industry for power steering, braking and suspension systems. These hoses facilitate the transfer of hydraulic fluid to ensure proper operation and control of these systems.

Factory View

Raw Material:

Imported rubber material Vietnam and Thailand

High tensile strength 2750Mpa steel wire from China's first-class factory

Powerful, safe and stable hydraulic hose products

Good dispersibility, high bearing pressure and superior pulse performance.

Excellent oil resistance, heat resistance and aging resistance.

Excellent bending resistance and fatigue resistance

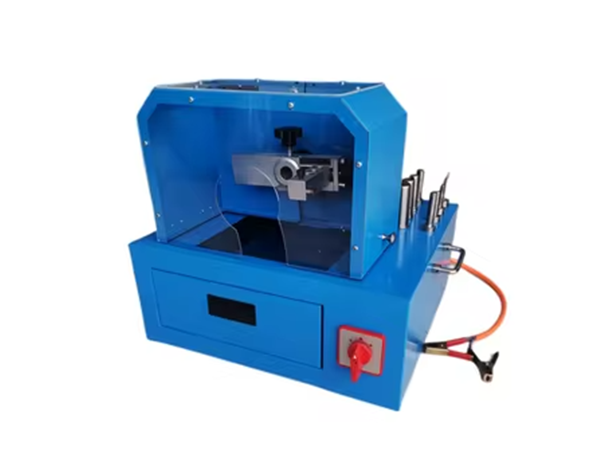

Factory Workshop:

Sinopulse is a 100% manufacturer of hydraulic hoses and industrial hoses, including all oilfields, agriculture, transportation, construction, mining, and forestry.

Daily output 500,000 meters of hoses, workshop covering 40,000 m²

40 production lines, involving high-speed joint machines, braiding machines, high-speed spiral machines, Italy VP automatic industrial machines, and Complete series Laboratory Testing Equipment

120 Skilled workers, 6 Engineers with 2 technical counselors from famous international companies,2 QC departments, and 2 warehouse managers are fall of our lovely people.

50 Sales and three groups of logistics specialists serve our clients from Italy, Germany, Uk, Spain, the USA, Canada, Brazil, Argentina, Panama, Peru, Chile, Viet Nam, Indonesia, Australia, Romania

Laboratory:

Our factory introduces a full range of laboratory testing equipment. It has advanced laboratory capabilities to conduct product quality testing and research and development work to ensure stable and excellent product quality.

After purchasing raw materials, we test each batch to ensure they meet our product's technical requirements.

After production, we test each hose, its working and burst pressure, and conduct a pulse test for each order to ensure that it is 100% qualified after leaving the factory.

We strive to provide our customers with top-notch hoses, doing everything we can to ensure their quality.

"Let our end users feel comfortable in use and safe in driving!" is our common goal.

Product packaging:

1. When packing hydraulic hoses, cartons or wooden boxes according to customer requirements.

2. We will pack the hose after finishing the hose production.

3. Generally, woven bags and plastic films are used for packaging.

4. Special packaging can be provided according to customer requirements. Special packaging is a request of Edible ACC Ording customers.

Download

Sinopulse Hydraulic Hose Catalog 2025

Hot Products

Related Product

What is SAE 100 R1?

SAE 100 R1 is a hydraulic hose. It is made for high pressure. It moves hydraulic fluid from one part to another. SAE means Society of Automotive Engineers. This group makes the rules for hoses. The number 100 shows the pressure level. The code R1 means the hose has one steel wire braid. The braid makes the hose strong. People use it in machines for building, farming, and industry.

What is SAE 100 R1 AT meaning?

SAE 100 R1 AT is a hydraulic hose. The letters AT mean “Type A – one wire braid.” The hose has one steel wire braid for strength. It follows SAE rules for safety and quality. It can carry oil, air, or water-based fluid. Many workers in farming, mining, and building use this hose.

What is SAE 100 R1 Hose?

SAE 100 R1 hose is a single wire braided hose. It has an inner tube of rubber. The rubber resists oil. It has a middle braid of steel wire. The braid gives it strength. It has an outside rubber cover. The cover resists weather and wear. People use this hose in hydraulic machines.

How many HP does the R1-04 have?

Hoses do not have horsepower. They have pressure ratings. The R1-04 hose is 1/4 inch wide inside. Its working pressure is 2,750 PSI. Its burst pressure is 11,000 PSI.

What is 100 R1 hose?

100 R1 hose is another name for SAE 100 R1 hose. It is a single wire braided hose. It works under high pressure. It can carry crude oil, fuel oil, lube oil, and antifreeze.

What do the numbers on the hydraulic hose mean?

The numbers show the hose size and rating. They show the ID , the outer width, and the pressure level.

What is the pressure rating of the SAE 100 R1 hose?

The rating changes with size. A 3/8 inch hose works at 3,000 PSI. A 1/2 inch hose works at 2,300 PSI. A 3/4 inch hose works at 1,500 PSI. A 1 inch hose works at 1,275 PSI.

What is the pressure rating of a 100 R1 hose?

The pressure depends on the size. It can be from 1,300 PSI to 3,600 PSI. You should check the hose manufacturer’s chart for the right number.

What is SAE 100 R1 AT?

SAE 100 R1 AT is a hose with one steel wire braid. It is used in machines that need medium or high pressure. It is common in mobile and industrial machines.

How do I read a hydraulic hose number?

The number on the hydraulic hose shows the size and pressure. For example, “1/4 – WP 3000 PSI” means the hose is 1/4 inch wide inside. It means the hose can work at 3,000 PSI.

Where to use SAE 100 R1 hose?

You can use R1 hose on farm machines. You can use it on digging and lifting machines. It works with oil, water, or mix fluids.

What is an R1 hose?

R1 hose is a single wire braided hose. It is made for medium pressure. It has a strong rubber cover. The cover protects the hose from cuts and wear.

What does 1/2 in SAE 100 R1 AT hydraulic hose mean?

The 1/2 means the hose is 1/2 inch wide inside. The name SAE 100 R1 AT means it is a single wire braided hose.

What are R1 hose specifications?

R1 hose works at medium pressure. The temperature range is from -40°C to +155°C. The inner tube is rubber. The braid is steel wire. The cover is rubber that resists weather and wear.

What is an R1 hydraulic hose?

R1 hydraulic hose has three parts. It has an oil-resistant rubber tube. It has one braid of steel wire. It has a rubber cover outside. The hose resists oil, heat, and aging. It can work between -40°C and +100°C.

What is the difference between R1 and R2 hydraulic hoses?

R1 hose has one steel wire braid. It works in medium pressure. R2 hose has two steel wire braids. It works in high pressure.

Do you supply SAE 100 R1 hose thread charts?

Yes, Sinopulse can supply them. Sinopulse makes SAE 100 R1 hoses. The hoses have one steel wire braid. They can work up to 3,600 PSI. We can give manuals and technical charts if needed.

What do R1, R2, R3 … R9 hoses mean?

The codes show the hose type and pressure level. R1 means single braid for medium pressure. R2 means two braids for higher pressure. Other numbers mean other builds and uses.

How is SAE 100 R1 hose made?

The hose has three layers. The inside is rubber that resists oil. The middle is a steel wire braid. The outside is rubber that resists oil, ozone, and wear. This makes the hose strong and long-lasting.

How to crimp the connector on SAE 100 R1 hose?

You do not need to cut the outer cover. You can crimp it with a crimping tool. You can use standard couplings or W series couplings.

How to find the best R1 or R2 hose manufacturer?

Choose a maker with certificates. Choose a maker that gives support. Choose a maker that shows test reports.

How to buy R1 or R2 hose from factories?

First, you need to know what you want. Then, you need to check suppliers and test samples. You can also visit the factory. After that, you should sign a contract. If your order is small, you can buy from a dealer. The price may be higher, but it is easier.

How can I find SAE 100 R1 hose suppliers for my shop?

You should look for stable quality. You should look for fair price. You should look for good service. Sinopulse can supply SAE 100 R1 hoses worldwide.

What is SAE 100R1 (R1AT) hose?

SAE 100R1, also called R1AT, R1, or EN853 1SN, is a medium-pressure hydraulic hose. It meets the Society of Automotive Engineers (SAE) standard. And used to transport hydraulic oil or water-based fluids. You can see it on forklifts, tractors, trucks, and construction machines. Many black hoses with steel wire braids are R1 hoses. It is a common hydraulic part in machines.

What is the structure of R1 hose?

R1 hose has three layers. The inner tube layer is oil-resistant rubber. It stops hydraulic oil from damaging the hose. The middle layer is steel wire braid. It helps the hose hold pressure. The outer cover layer is good quality rubber. It protects the inner layers from wear, aging, sun, and ozone. The hose lasts long even outdoors.

How is SAE 100R1 hose different from normal rubber hose?

Normal rubber hoses work at low pressure, like for water or air. They can burst under high-pressure hydraulic systems. R1 hoses have a steel wire layer. They hold more pressure. They are built for hydraulic systems. They are safer and last longer than normal hoses.

What is the difference between SAE 100R1 and R4 hose?

R1 and R4 have different uses. R1 is for high-pressure oil, like from pump to cylinder. R4 hose is for suction or return oil. It has spiral steel inside to prevent it from collapsing. R4 is used from tank to pump. You should not replace R4 with R1.

What is the difference between SAE 100R1 and R5?

R5 is also a high-pressure hose, but it is stronger. It has two layers: steel reinforce inside and fiber or other braid cover outside. It is more wear-resistant and shock-resistant. R5 is for machines that need more safety, like mining or heavy equipment.

What fluids can R1 hose carry?

R1 hose transports mineral-based hydraulic oil and water-based fluids. Most regular hydraulic systems can use it. It should not carry gasoline, diesel, or compressed gas unless the manufacturer allows it.

What machines or industries use R1 hose?

R1 hose is used in many machines. Tractors, harvesters, excavators, loaders, forklifts, machine tools, hydraulic stations, and injection machines all use it.

What is the working and burst pressure of R1 hose?

Pressure depends on the hose size. Small hoses size, like 3/16 inch, can hold about 250 bar (3600 psi). Burst pressure is about 4 times working pressure, around 1000 bar (14500 psi). Larger hoses, like ½ inch, may hold only 160 bar. Choose size by pressure needs.

What is the temperature range of R1 hose?

R1 hose works from -40°C to 100°C. It does not crack in cold. It does not soften in heat. This range fits most machines and mobile equipment.

Can SAE 100R1 and EN853 1SN replace each other?

Yes. SAE is US standard. EN853 1SN is European standard. They have the same structure, size, and pressure. Many makers mark both standards. You can replace one with the other on site.

Which brand hoses can R1-04 replace?

R1-04 means R1 hose with ¼ inch (6mm) inner diameter. It can replace many brands like Aeroquip FC211, Parker 421 series, Weatherhead H104. If size and fittings match, they can be used interchangeably.

What fittings work with R1 hose?

Use fittings made for r1 braided hoses. They are crimped on the hose. Common types are threaded or quick couplings. Fittings must match hose size and be crimped well. Otherwise, oil may leak or the hose may fail.

What are the common R1 hose sizes?

Common sizes are R1-04, R1-06, and R1-10. Divide the number by 4 to get inches: R1-04 is ¼ inch (6mm), R1-06 is ⅜ inch (10mm), R1-10 is ⅝ inch (16mm). These sizes are easy to buy and replace.

Do different sizes have different pressure limits?

Yes. Small hoses hold more pressure. Large hoses hold less pressure per area. For example, ¼ inch r1 hose can hold 250 bar. ½ inch r1 hose may hold 160 bar. Always check pressure before replacing or designing a line.

How to choose an R1 hydraulic hose?

Check r1 system pressure, flow, hose diameter, and length. And look at the installation path for bends or friction. the temper your application is also need to consider, like heat, cold, or sun.

How to maintain R1 hose?

Check the r1 hose for cracks, bulges, wear, or leaks. Check clamps and supports. Listen for strange sounds and watch fittings for leaks. Keep the hose clean. Avoid heavy pressure and frequent bends.

How long does an R1 hose last?

R1 hose lifespan is normally 3 to 5 years. High heat, vibration, sun, or chemicals shorten life. Check hoses regularly to decide if replacement is needed.

How to replace an R1 hose?

Choose a certified new r1 hose. Match fittings and crimp properly. Release pressure before removing old hose. Remove air from the system after installation. Test at low pressure first. Only use normally after no leaks are seen.

How to choose a reliable SAE 100R1 hose manufacturer?

You may check for certifications like ISO9001 or MSHA. And look at production quality and stable materials. Many manufacturers have tested every batch for pressure and burst, you could ask the video of hose test. Then check reviews and long-term customers. Good makers give support and reliable SAE 100R1at hydraulic hose product!