Stainless Steel PTFE Hose

Sinopulse, a leading PTFE hose manufacturer in China, is pleased to introduce our range of PTFE hoses.

PTFE hoses, also known as PTFE flexible hoses or stainless steel braided PTFE hoses, are flexible conduits coated with an inner layer of PTFE (polytetrafluoroethylene). These hoses offer excellent resistance to chemicals, high temperatures, abrasion, and corrosion, making them the ideal choice for handling aggressive chemicals and high-temperature fluids.

PTFE hose has excellent temperature characteristics in both high and low temperatures, excellent chemical resistance, non-contamination properties, low coefficient of friction and resists deterioration. Therefore, the hose is generally used in applications where all or one of the above properties is the main criterion.

CONSTRUCTION:

Tube: PTFE (polytetrafluoroethylene).

Cover: Single braid of AISI #304 series stainless steel wire

TEMPERATURE: -55 °C to +210 °C (intermittent 260 °C).

Pressure range: 1500 psi - 600 psi

Size range: 3/16” – 1-1/4”

CONSTRUCTION:

Tube: PTFE (polytetrafluoroethylene), Corrugated tube.

Cover: Single braid of AISI #304 series stainless steel wire

TEMPERATURE: -55 °C to +210 °C (intermittent 260 °C).

APPLICATION:

PTFE hose has excellent temperature characteristics in both high and ...

CONSTRUCTION:

Tube: PTFE (polytetrafluoroethylene).

Cover: Single braid of AISI #304 series stainless steel wire

TEMPERATURE: -55 °C to +210 °C (intermittent 260 °C).

APPLICATION:

PTFE hose has excellent temperature characteristics in both high and low temperatures, ...

Our custom, precision machined fittings will provide you with truly reliable PTFE HOSE ASSEMBLIES for all your demanding applications.

CONSTRUCTION:

Tube: PTFE (polytetrafluoroethylene).

Cover: Single braid of AISI #304 series stainless steel wire

TEMPERATURE: -55 °C to +210 °C (intermittent 260 °C).

CONSTRUCTION:

Tube: PTFE (polytetrafluoroethylene), Corrugated tube.

Cover: Single braid of AISI #304 series stainless steel wire

TEMPERATURE: -55 °C to +210 °C (intermittent 260 °C).

PTFE hose has excellent temperature characteristics in both high and low temperatures, excellent chemical resistance, non-contamination properties, low coefficient of friction and resists deterioration. Therefore, the hose is generally used in applications where all or one of the above properties is the main criterion.

Sinopulse specializes in the design and manufacture of PTFE flexible hoses. With over 20 years of experience, we produce some of the world’s most technologically advanced PTFE flexible hose products. From design to production, our factory handles every step of the process, ensuring that we can meet the specific needs of any application. Our commitment to quality and reliability has earned us the trust of our customers, who rely on our hoses as the most dependable choice for their manufacturing operations.

PTFE hoses are highly versatile and suitable for a wide range of applications, including the transportation of compressed gases, fuels, chemicals, and steam. These hoses are also commonly used in industries such as pharmaceuticals, power generation, and automotive, where they serve as suction, delivery, and discharge hoses. Additionally, Sinopulse PTFE hoses are ideal for applications in food, pharmaceutical, and chemical industries.

Features

- Chemical Resistance: PTFE hose assemblies can handle a wide variety of fluids.

- Chemically Inert: PTFE hoses will not crack or degrade during use in chemical applications.

- Medium and High Pressure: PTFE hoses are available for both medium and high-pressure applications.

- Excellent Cleanability: PTFE hoses are easy to clean, ensuring optimal performance.

- Durability and Flexibility: Strong yet flexible, PTFE hoses can withstand vibration and continuous flexing.

Application:

These PTFE hoses are widely used across various demanding applications, including compressed gas and industrial sectors. The smooth bore hose features a low-friction surface that allows for high flow rates, while also being easy to drain and clean. Stainless steel PTFE hoses are commonly found in industries such as chemicals, automotive, aerospace, and pharmaceuticals. They are frequently used in chemical processing equipment, high-temperature fluid delivery systems, hydraulic systems, air conditioning and refrigeration systems, fuel delivery systems, and other machinery.

Fluid Compatibility: Air and gas, alcohol, brake fluid, coolant, engine oil, ethanol fuel (E85+), ethanol/gasoline blends, gear oil, methanol, nitro, methane monoxide, nitrogen, power steering fluid, racing fuel, transmission fluid, vacuum, and water.

Chemical PTFE hoses, Bleach and chlorine PTFE hoses, Bromine PTFE hoses, Steam PTFE hoses, Acid PTFE hoses, Compressed natural gas (CNG) PTFE hoses, Natural gas PTFE hoses, Oil PTFE hoses, Pump hoses and pump connectors PTFE hoses, Fuel PTFE hoses, Coolant hoses, Solvent and paint PTFE hoses, Alcohol PTFE hoses, Medical PTFE hoses

PTFE Hoses Structure

Tube: temperature chemical resistant PTFE material.

Cover: Braided with stainless steel.

PTFE Hoses Feature

Temperature Range: -60℃ to +260℃.

Working pressure: depends on temperature.

Main Applications: for carrying chemicals and use with petroleum base hydraulic fluids. pharmaceutical and chemical fluids transfer, and in many automotive and aerospace applications

Conductivity: Conductive (black) and non-conductive (white) PTFE hose assemblies are available

Fittings: Fittings for your PTFE hoses are available with or without PTFE linings, tailored to your specifications. These fittings can be made from brass, stainless steel, Hastelloy, carbon steel, or titanium. Both standard and custom accessory configurations are available.

Applicable Standards: SAE J517 100R14

SAE 100R14 SS PTFE Hose Technical Specification

| Hose Size (dash) | Hose Size (inch) | I.D. (mm) Min | I.D. (mm) Max | O.D. (mm) Min | O.D. (mm) Max | Max W.P. (MPa) | Max W.P. (PSI) | P.P (MPa) | P.P (PSI) | Min B.P. (MPa) | Min B.P. (PSI) | Min B.R (inch) | Min B.R (mm) | Ref. W.T. (kg/m) |

| Braided Stainless PTFE Hose -3 | 3/16” | 3.2 | 4.3 | 5.3 | 6.8 | 10.5 | 1523 | 41.4 | 5002 | 82.7 | 11990 | 1.57 | 40 | 0.08 |

| Braided Stainless PTFE Hose-4 | 1/4” | 4 | 5 | 6.4 | 8.2 | 10.5 | 1523 | 41.4 | 5002 | 68.9 | 9990 | 1.97 | 50 | 0.11 |

| Braided Stainless PTFE Hose-5 | 5/16” | 4.8 | 6.6 | 6.9 | 10.1 | 10.5 | 1523 | 41.4 | 5002 | 62.4 | 9054 | 2.36 | 60 | 0.14 |

| Braided Stainless PTFE Hose-6 | 3/8” | 6.3 | 7.5 | 8.4 | 10.4 | 10.5 | 1523 | 41.4 | 5002 | 55.2 | 8007 | 2.76 | 70 | 0.19 |

| Braided Stainless PTFE Hose-7 | 7/16” | 10 | 11 | 10.1 | 11.6 | 9.7 | 1406 | 38.8 | 4495 | 48.2 | 6985 | 3.15 | 80 | 0.21 |

| Braided Stainless PTFE Hose-8 | 1/2” | 12.5 | 13.3 | 13 | 15.3 | 8.4 | 1218 | 34.5 | 3965 | 41.4 | 6003 | 3.54 | 90 | 0.29 |

| Braided Stainless PTFE Hose-10 | 5/8” | 15.3 | 16.3 | 15.6 | 18.1 | 7 | 1015 | 28.1 | 3109 | 27.6 | 4003 | 4.72 | 120 | 0.44 |

| Braided Stainless PTFE Hose-12 | 3/4” | 18.4 | 19.8 | 20.1 | 23.3 | 5.6 | 812 | 22.6 | 2369 | 24.3 | 3527 | 6.5 | 165 | 0.59 |

| Braided Stainless PTFE Hose-14 | 7/8” | 21.4 | 23 | 21.4 | 23.6 | 5.6 | 812 | 22.6 | 2369 | 17.2 | 2494 | 7.09 | 180 | 0.63 |

| Braided Stainless PTFE Hose-16 | 1” | 25 | 26.6 | 26.6 | 31.9 | 4.2 | 609 | 16.8 | 2436 | 13.8 | 2001 | 9.06 | 230 | 0.86 |

| Braided Stainless PTFE Hose-18 | 1 1/8” | 28.7 | 29.4 | 29.7 | 33.5 | 4.2 | 609 | 16.8 | 1812 | 10.6 | 1537 | 10.63 | 270 | 0.59 |

| Braided Stainless PTFE Hose-20 | 1 1/4” | 29.7 | 29.8 | 31.9 | 33.7 | 4.2 | 609 | 16.8 | 1812 | 8.6 | 1247 | 16.14 | 410 | 0.664 |

Find a trusted hose factory. Any requirements and problems can ask us at any time.

Why Choose Sinopulse

At Sinopulse, we collaborate closely with you and your team to create the optimal solution for your specific application needs. Selecting the right PTFE hose manufacturer is crucial to achieving the best hose assembly for your critical fluid transfer applications.

Our team of experts is available to answer any questions you may have about our products or manufacturing capabilities. Whether you require a custom specialty product, a high-volume order, or simply need assistance getting started, you can chat live with one of our experts on our website.

What is PTFE Hose

PTFE hose is a highly versatile and durable alternative to rubber hoses. Polytetrafluoroethylene (PTFE) is used as an inner tube for stainless steel braided cover hoses to enhance temperature range compatibility, chemical resistance, flexibility, and impact resistance. Its unique properties, including exceptional chemical and temperature resistance, make it a popular choice among engineers and facility managers.

What are the advantages of PTFE hoses

PTFE hoses offer excellent chemical resistance, making them suitable for a wide range of media. They are capable of withstanding both high and low temperatures, performing well in extreme conditions. Each PTFE hose features a low-friction surface, which minimizes pressure drop and prevents the buildup of unwanted deposits. Additionally, PTFE hoses are moisture-resistant, helping to prevent hydrolysis.

What fields can PTFE hose be used in?

It can be applied to many fields, such as: automotive hose, biotechnology and pharmaceuticals hose, industrial processes hose, water and wastewater treatment hose, food and beverages hose

Can PTFE hose be used in the food and beverage industry

Dissolved oxygen (DO) is a significant concern in the food and beverage industry, especially due to the repetitive motion of food and beverage processing equipment. PTFE and PTFE-lined hoses are ideal for efficient product transfer and handling in these applications, offering an exceptionally long service life. Their design maintains a smooth, round bore without deformation, ensuring a smooth, consistent flow with minimal turbulence.

Why PTFE materials

Stainless steel is an excellent choice for metal-filled PTFE when high temperature and wear resistance are required. Typically, 50% by weight (equivalent to 15% by volume) of stainless steel is added to enhance the thermal conductivity of the PTFE material under load at extreme temperatures and reduce load-induced deformation.

Stainless steel-filled PTFE materials offer excellent wear resistance and compressive strength, making them ideal for valve seats and seals in high-temperature and steam applications.

Additionally, stainless steel-filled PTFE is highly machinable and complies with FDA and EC regulations, making it the preferred material in the food processing industry.

What is SAE 100R14 SS PTFE Hose

R14 Stainless steel PTFE hose combines a white extruded PTFE tube with a stainless steel braided cover, ensuring superior chemical resistance and thermal stability over a range of -65°F to 450°F. This hose is ideal for industries such as chemical, pharmaceutical, and food processing where the hose encounters high temperatures and corrosive substances.

Tube: White extruded PTFE

Cover: Stainless steel braid

Temperature operating range: -65°F to +450°F

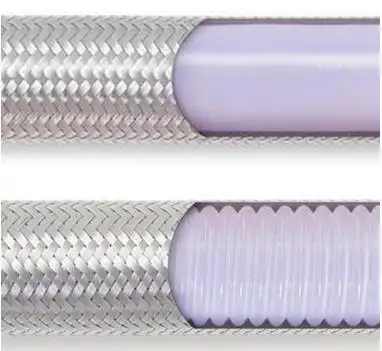

Smooth bore PTFE hose vs Convoluted bore PTFE hose

Smooth bore PTFE hoses

Smooth bore hoses are used as an alternative to silicone hoses for increased compatibility and cleanability.

Smooth bore hoses are suitable for chemical and other fluid flow applications where rough use may occur.

Smooth bore hoses are suitable for most automotive and general purpose applications. They can be used at high pressures.

Smooth bore hoses are suitable for all applications where increased flexibility and kink resistance are required.

Convoluted bore PTFE hoses

Convoluted bore hoses are used to transfer process fluids where a smooth bore is not a specific requirement.

Corrugated bore hoses are suitable for all applications where smooth bore and/or high pressure is not required

Difference between Conductive PTFE hoses and Non-conductive PTFE hoses

PTFE hoses feature a PTFE liner with either a braided or rubber outer layer. Conductive PTFE hoses have a black, conductive PTFE core, making them suitable for handling media that may generate static electricity. In contrast, non-conductive PTFE hoses have a white, non-conductive PTFE core, which prevents the transfer of static charge.

When to Choose Smooth Bore Fluoropolymer (PTFE) Hose

Medium-pressure smooth bore fluoropolymer (PTFE) hose (3000 PSI) features a PTFE hose core reinforced with a stainless steel wire braid outer layer for strength and protection. This flexible water hose is used in a wide variety of applications, including demanding compressed gas and industrial applications. The low friction surface of the smooth bore hose provides high flow rates, and these hoses are easy to drain and/or clean.

When to Choose Convoluted PTFE Hose

Convoluted PTFE Hose is manufactured with smooth, round, spiral corrugations that help promote easy cleaning and self-draining for the ultimate high-purity corrugated hose. The key features of corrugated hose are its light weight and its flexibility providing excellent flex life.

What are the brands of PTFE hoses

Sinopulse, Bioflex Ultra, titeflex, pureflex, Aflex

How to choose the right length of PTFE hoses

Bulk hose can be cut to the desired length and compatible fittings can then be installed on the end of the hose to enable it to be connected to tools and equipment. Hose assemblies come with fittings already installed on the end of the hose for quick connection to tools and equipment.

Why Choose Sinopulse

Sinopulse specializes in the design and manufacture of PTFE-lined flexible hoses. We work closely with you and your team to develop the best solution for your specific application needs. Selecting the right PTFE hose manufacturer is crucial to ensuring you get the optimal hose assembly for your most demanding fluid transfer applications.

Our experienced consultants are here to help you choose the right hose for your requirements. We can assist in determining whether your application calls for a smooth bore or corrugated PTFE hose, rubber-covered or stainless steel braided, or even a simple PTFE tube.

At Sinopulse, we go beyond being just a supplier; we are problem solvers committed to providing you with the perfect industrial hose for your needs. When you require the highest quality hoses and exceptional customer service, we are here for you. We offer industrial PTFE hose solutions around the clock. Whether it’s a midnight emergency requiring an immediate hose replacement or a need for guidance to optimize hose lifecycle, we have the expertise to support your operations successfully.