Thermoplastic Hose

Thermoplastic hose R7/R8

Thermoplastic hose is a kind of hose made of thermoplastic that can be heated up to 120 degrees and is powered by water pressure or pneumatic. It has the characteristics of lightweight, pressure resistance and corrosion resistance. Our SAE thermoplastic hoses have two layers of braided synthetic fibers and a polyurethane outer coating, making them abrasion resistant. Rated up to 212 F(100°C), the thermoplastic hoses are used in many hydraulic applications. Thermoplastic hydraulic hoses offer excellent abrasion resistance and flexibility, and are resistant to a wide range of chemicals.

Thermoplastic hoses are used to convey various fluid media, such as water and petroleum inside. Used in chemical machinery, printing machinery, plastic machinery, electronic manufacturing equipment, food packaging industry, medical equipment, and auto parts.

ID Size range: 1/8", 5/16", 1/4", 1/2", 1", and other custom sizes

TEMPERATURE: -40°C to +100°C (intermittent 110°C).

Our SAE 100R7 Thermoplastic Hydraulic Hose range is designed for medium pressure hydraulic and pneumatic systems and meets or exceeds the SAE 100R7 standard. It features an oil resistant seamless thermoplastic elastomer inner core, reinforced with high strength synthetic fibers and a highly abrasion resistant polyurethane outer layer, making ...

Our SAE 100R7 Thermoplastic Hydraulic Hose Series is designed for medium pressure hydraulic and pneumatic systems and meets or exceeds the SAE 100R7 standard. It features an oil resistant seamless thermoplastic elastomer inner core, reinforced with high strength steel wire, and a highly abrasion resistant polyurethane outer layer, making ...

The SAE 100R7 Orange Non-Conductive Thermoplastic Hydraulic Hose is made with a thermoplastic elastomer inner core to ensure consistent reliability in a variety of high-pressure applications. Designed for medium-pressure hydraulic and pneumatic systems, it meets or exceeds the requirements of SAE 100R7. It features an oil-resistant synthetic polyester inner ...

The Thermoplastic Hydraulic Hose SAE 100R7 (Black) Twin Line is designed for medium-pressure hydraulic and pneumatic systems, meeting or exceeding the requirements of SAE 100R7. Ideal for pneumatic or gas systems, this hose has an inner core made of oil resistant synthetic polyester tubing reinforced with braided high-strength synthetic ...

The SAE 100R8 Thermoplastic Hydraulic Hose is designed for hydraulic and pneumatic systems requiring pressure ratings above SAE 100R7. It features an oil-resistant, seamless thermoplastic elastomer core reinforced with braided high-tensile aramid fibers for added strength and durability. The high-abrasion resistant polyurethane outer layer ensures long-lasting durability in demanding ...

SAE 100R8 Thermoplastic Hydraulic Hose is designed for hydraulic and pneumatic systems requiring pressure ratings higher than SAE 100R7. It features an oil-resistant seamless thermoplastic elastomer core reinforced with a steel wire braid for increased strength and durability. Highly abrasion resistant polyurethane outer layer ensures long-lasting durability in demanding ...

SAE 100R8 Non-Conductive Thermoplastic Hydraulic Hose is designed for hydraulic and pneumatic systems requiring pressure ratings above the 100R8 standard. Its oil-resistant thermoplastic elastomer inner core is reinforced with braided high tensile aramid fibers for strength and flexibility. The non-conductive, highly abrasion-resistant polyurethane outer layer ensures durability and protection, ...

The Twin-Line Thermoplastic Hydraulic Hose, designated SAE 100R8 (Black) Twin-Line, is designed for medium-pressure hydraulic and pneumatic systems and meets or exceeds SAE 100R8 standards. Ideal for pneumatic or gas applications, perforated (needle-punched) hose is recommended. Its construction features an oil-resistant synthetic polyester inner core reinforced with braided high-strength ...

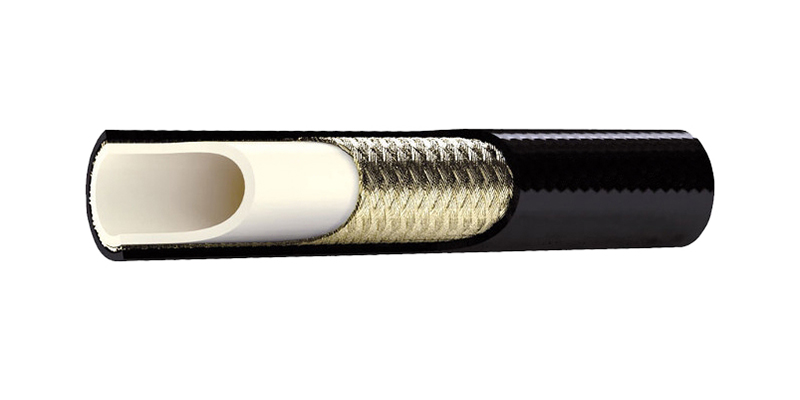

Thermoplastic Hydraulic Hose Construction:

Tube: PA (polyamide), Thermoplastic Elastomer, oil-resistant

Reinforcement: One or Two layer of high tensile steel/ fiber wire braided.

Cover: PU (polyurethane) Synthetic Rubber, black, Vulcanized Abrasion and Weather Resistant, MSHA Certified

Thermoplastic Rubber Hose Application:

Mainly transfer mineral and biological oils, water-glycol based, water, lubricants. Thermoplastic hydraulic hoses withstand extreme temperatures, abrasive chemicals and harsh environments such as forklift, machine tool and manlift applications

Thermoplastic Hoses Advantages:

Lightweight - 2x lighter than equivalent wire braided rubber hose

Long service life - highly abrasion resistant cover

Custom applications - multi-wire bonding and thermoforming

Withstands extreme environmental conditions and high wear applications, such as forklifts and telehandlers - with nylon and polyester hoses cover

Resists ozone, UV and aging - TPU and polyester outer layer

Chemical and low temperature resistance - thermoplastic composition

Permeation resistance - thermoplastic hose

Lightweight and thin outer diameter - thermoplastic hoses are lighter and more compact than rubber hoses of the same inner diameter

Clean core - unlike rubber cores, thermoplastic cores do not introduce debris into the hose interior, greatly reducing the risk of contamination in the hydraulic system.

Lower volume expansion - faster response time than rubber hoses.

Thermoplastic Hose Feature:

Inside diameter range: 1/8” to 1”

Working pressure range:

SAE 100R7 - 1015psi to 3335 psi

SAE 100 R8 - 1450psi to 5133psi

Safety Factor: 4:1

Temp Operating Range: -40°F/-40°C to 212°F/100°C ( intermittent +248°F/120°C max.)

Hose Interchange:

SAE 100R7 - Synflex 37NC 3130-02, Weatherhead H435 H43602 H436, Parker 510A/ 518A 540N-2, Aeroquip FC373 FC372-02, Gates 2C7S

SAE 100 R8 - Weatherhead H336, Aeroquip FC374, Synflex 3800, Parker's 520N/528N

Certification: MSHA and ISO9001:2015 and GOST and SGS Approved.

Standard: SAE 100R7, SAE 100R8 (Textile Braided / Steel Braided / Non-Conductive /Double Line )

SAE 100R7 Thermoplastic Hydraulic Hose Technical Specification

Our SAE 100R7 Thermoplastic Hydraulic Hose range is designed for medium pressure hydraulic and pneumatic systems and meets or exceeds the SAE 100R7 standard. It features an oil resistant seamless thermoplastic elastomer inner core, reinforced with high strength synthetic fibers and a highly abrasion resistant polyurethane outer layer, making it durable in demanding environments. With an operating temperature range of -40°F to +212°F, it is suitable for a wide range of industrial applications.

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m | Codigo | Codigo |

| SNP-R7C02 | R7-02 | 3.2 | 1/8" | 3.4-3.6 | 8.5 | 230 bar | 3335 psi | 920 bar | 13340 psi | 12 | 0.038 | 90-110 | ××××1-××-02 | 00018-02 |

| SNP-R7C03 | R7-03 | 4.8 | 3/16" | 4.6-5.4 | 10.8 | 210 bar | 3045 psi | 840 bar | 12180 psi | 30 | 0.080 | 90-110 | ××××1-××-03 | 00018-03 |

| SNP-R7C04 | R7-04 | 6.4 | 1/4" | 6.2-7.0 | 13.0 | 200 bar | 2900 psi | 800 bar | 11600 psi | 35 | 0.120 | 90-110 | ××××1-××-04 | 00018-04 |

| SNP-R7C05 | R7-05 | 7.9 | 5/16" | 7.7-8.5 | 15.1 | 190 bar | 2755 psi | 760 bar | 11020 psi | 45 | 0.145 | 90-110 | ××××1-××-05 | 00018-05 |

| SNP-R7C06 | R7-06 | 9.5 | 3/8" | 9.3-10.1 | 17.0 | 175 bar | 2538 psi | 700 bar | 10150 psi | 55 | 0.170 | 90-110 | ××××1-××-06 | 00018-06 |

| SNP-R7C08 | R7-08 | 12.7 | 1/2" | 12.3-13.5 | 20.7 | 140 bar | 2030 psi | 560 bar | 8120 psi | 75 | 0.250 | 90-110 | ××××1-××-08 | 00018-08 |

| SNP-R7C10 | R7-10 | 15.9 | 5/8" | 15.5-16.7 | 23.0 | 105 bar | 1523 psi | 420 bar | 6090 psi | 120 | 0.300 | 45-55 | ××××1-××-10 | 00018-10 |

| SNP-R7C12 | R7-12 | 19.1 | 3/4" | 18.6-19.8 | 26.0 | 90 bar | 1305 psi | 360 bar | 5220 psi | 145 | 0.346 | 45-55 | ××××1-××-12 | 00018-12 |

| SNP-R7C16 | R7-16 | 25.4 | 1" | 25.0-26.4 | 32.0 | 70 bar | 1015 psi | 280 bar | 4060 psi | 200 | 0.422 | 45-55 | ××××1-××-16 | 00018-16 |

SAE 100R8 Thermoplastic Hydraulic Hose Technical Specification

SAE 100R8 Thermoplastic Hydraulic Hose is designed for hydraulic and pneumatic systems that require pressure ratings above SAE 100R7. It features an oil resistant seamless thermoplastic elastomer core, reinforced with braided high tensile aramid fibers for increased strength and durability. Highly abrasion-resistant polyurethane outer layer ensures durability in demanding environments and operates in temperatures ranging from -40°F to +212°F (-40°C to +100°C)

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | Ferrule & Fitting Code | |||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m | Codigo | Codigo |

| SNP-R8C02 | R8-02 | 3.2 | 1/8" | 3.4-3.6 | 10.2 | 354 bar | 5133 psi | 1416 bar | 20532 psi | 20 | 0.09 | 90-110 | ××××1-××-02 | 00018-02 |

| SNP-R8C03 | R8-03 | 4.8 | 3/16" | 4.6-5.4 | 13.1 | 345 bar | 5003 psi | 1380 bar | 20010 psi | 40 | 0.120 | 90-110 | ××××1-××-03 | 00018-03 |

| SNP-R8C04 | R8-04 | 6.4 | 1/4" | 6.2-7.0 | 15.9 | 345 bar | 5003 psi | 1380 bar | 20010 psi | 50 | 0.160 | 90-110 | ××××1-××-04 | 00018-04 |

| SNP-R8C05 | R8-05 | 7.9 | 5/16" | 7.7-8.5 | 17.0 | 300 bar | 4350 psi | 1200 bar | 17400 psi | 65 | 0.175 | 90-110 | ××××1-××-05 | 00018-05 |

| SNP-R8C06 | R8-06 | 9.5 | 3/8" | 9.3-10.1 | 19.0 | 276 bar | 4002 psi | 1104 bar | 16008 psi | 75 | 0.190 | 90-110 | ××××1-××-06 | 00018-06 |

| SNP-R8C08 | R8-08 | 12.7 | 1/2" | 12.3-13.5 | 22.7 | 240 bar | 3480 psi | 960 bar | 13920 psi | 102 | 0.300 | 90-110 | ××××1-××-08 | 00018-08 |

| SNP-R8C10 | R8-10 | 15.9 | 5/8" | 15.5-16.7 | 25.0 | 185 bar | 2683 psi | 740 bar | 10730 psi | 150 | 0.360 | 45-55 | ××××1-××-10 | 00018-10 |

| SNP-R8C12 | R8-12 | 19.1 | 3/4" | 18.6-19.8 | 29.0 | 135 bar | 1958 psi | 540 bar | 7830 psi | 180 | 0.370 | 45-55 | ××××1-××-12 | 00018-12 |

| SNP-R8C16 | R8-16 | 25.4 | 1" | 25.0-26.4 | 34.0 | 100 bar | 1450 psi | 400 bar | 5800 psi | 230 | 0.490 | 45-55 | ××××1-××-16 | 00018-16 |

Hot Products

Thermoplastic hoses are often used as an alternative to rubber hydraulic hoses when you need a cleaner working environment. Thermoplastic hoses also feature a non-conductive outer shell manufactured with rubber. Sinopulse offers a large selection of high-quality thermoplastic hoses for a variety of applications, including mobile hydraulic machinery, factory equipment, and more.

What is Thermoplastic Hose?

Made with a thermoplastic elastomer inner core, these hydraulic hoses offer flexibility and optimal performance, ensuring reliability in a variety of high-pressure applications. The outer cover is MSHA-approved with a vulcanized, abrasion-resistant, and weather-resistant synthetic rubber to increase durability and extend hose life. Cleaner, lighter, and more flexible than wire-reinforced hoses, thermoplastic hoses are ideal for forklifts, snowplows, and other hydraulic applications. Dual hoses and non-conductive hoses are available.

What can thermoplastic hoses be used for?

Thermoplastic hoses are designed to withstand extremely high temperatures. Typically, thermoplastic hoses have a high level of contact strength between the tube layers, reinforcement layers, and cover layers. This high level of contact occurs because thermoplastic materials can be re-melted during the production process, allowing for chemical and mechanical bonding. The inner tube of a thermoplastic hose is typically made from plastics such as polyamides, polyesters, and fluoropolymers. The specific polymer used in the hose depends on design factors such as pressure capabilities, compatibility with the fluid to be conveyed, operating temperature range, abrasion resistance, and resistance to degradation from chemicals, solvents, cleaning fluids, salt water, ozone, and UV radiation. Thermoplastic hoses are typically made with one or two reinforcement layers to provide strength and pressure resistance. These reinforcement layers are typically braided and made from materials such as polyester fibers, polyamide fibers, or steel wire. One of the most important factors in the construction of a thermoplastic hose is how the tube layers, reinforcement layers, and cover layers are bonded together. Thermal and chemical bonding methods ensure a strong bond between the layers because the thermoplastic material can be re-melted during the production process.

Thermoplastic hydraulic hoses differ from regular hydraulic hoses because they are designed to withstand extreme temperatures and environmental factors that would cause rubber hoses to deteriorate prematurely. Due to this manufacturing process, thermoplastic hoses also have a self-supporting inner tube and cure without a mandrel. Due to this manufacturing process, thermoplastic hoses can be made in extremely long lengths - some continuous hoses are up to 8,000 meters long.

Thermoplastic Hose Advantages

Lightweight – weighs only 30-50% of conventional rubber hoses. Reduced diameter allows for the use of larger capacity hose reels.

Reduced bend radius – Thermoplastic hoses ensure easier routing in confined and tight enclosed areas.

Longer shelf life – This type of high pressure hose will not deteriorate when stored under the correct conditions.

Minimal volume expansion – Due to the lower elongation characteristics of the reinforcing yarn braid, thermoplastic hoses ensure reduced pressure loss, faster response time in hydraulic circuits, and reduced oil/fluid consumption.

Easier to handle – Generally, thermoplastic hoses are easy to clean and handle in the workshop. Fabric braided hoses do not require high powered cutting equipment to cut/prepare, in some cases simple hand or blade cutting equipment can be used.

Thermoplastic hose application

Thermoplastic Hose for LPG Applications up to 30 bar

Thermoplastic Hose for LPG Applications up to 30 bar This thermoplastic hose has a polyamide 6 core and is used in low pressure LPG systems. The thermoplastic hose has a black abrasion resistant outer layer and is suitable for fuel, gas and LPG applications. It is ideal for LPG applications up to 30 bar and has a non-metallic, lightweight design for easy handling and operation.

CNG Thermoplastic Hose - Pressures up to 350 bar

Thermoplastic Hose for CNG - Pressures up to 350 bar This type of thermoplastic hose is a high pressure hose for CNG refueling applications and has a conductive inner tube that dissipates static electricity build-up. This hose has an extra strong outer layer that resists abrasion, water and microorganisms. The thermoplastic hose is a non-metallic type and has a lightweight design for easy handling and operation. The thermoplastic hose has a strong construction for CNG refueling applications.

Thermoplastic hose - for CO2 fire extinguishing applications - up to 300 bar

Thermoplastic hose - for CO2 fire extinguishing applications - up to 300 bar This type of thermoplastic hose is used as a connection between the bottle/valve and the manifold of the CO2 main fire extinguishing system. The low temperature resistance of the outer layer prolongs the service life of these hoses. The fire extinguishing thermoplastic hose has been approved by the Italian MSHA (Mine Safety and Health Administration) under the number IC-305.

Thermoplastic hose for H2 - up to 700 bar

Thermoplastic hose for H2 - up to 700 bar This is a very high pressure thermoplastic hose for hydrogen refueling applications. Thermoplastic hose for hydrogen has a metal braid and a special conductive inner tube to eliminate static electricity build-up. This type of thermoplastic hose has an extra strong outer layer, is abrasion resistant and is anti-microbial. Thermoplastic hose for hydrogen is used as a connecting hose.

Thermoplastic hose for high pressure lubrication applications - up to 400 bar

Thermoplastic hose - for high pressure lubrication applications - up to 400 bar The thermoplastic hose on offer is designed for lubrication applications with pressures up to 400 bar. Suitable for use with petroleum or synthetic or water-based hydraulic oils, this high pressure hose is designed for a wide range of lubrication applications in industrial vehicles and hand-held or automatic lubrication dispensing equipment - different versions are available to meet a wide range of needs.

Thermoplastic hose - for beverage dispensing - up to 350 bar

Thermoplastic hose - for beverage dispensing - up to 350 bar This thermoplastic hose is designed for use in high pressure beverage dispensing equipment from 210 to 350 bar (3000 to 5000 psi). This is a high pressure hose particularly suitable for gases (including mixed gases) used in stationary and mobile beverage dispensing installations. The thermoplastic hose for this beverage application has an odorless inner tube. The thermoplastic hose is suitable for food applications.

Thermoplastic hose - for cylinder filling - up to 420 bar

Thermoplastic hose - for cylinder filling - up to 420 bar This type of high-pressure thermoplastic hose is particularly suitable for filling cylinders. The maximum pressure is approximately 420 bar. The aramid reinforcement of the thermoplastic hose increases its service life while reducing the risk of injury. Our thermoplastic hoses for cylinder filling are made of odorless material, eliminating the risk of contamination.

Benefits of Using PTFE

Nylon braided hose (PTFE) helps prevent gas odors from penetrating the hose itself and prevents odors from entering your workshop or garage. This hose is resistant to all types of fluids and chemicals, including gasoline, ethanol, transmission fluid, brake fluid, power steering fluid, and antifreeze. Rubber is not as resistant to these fluids as PTFE because the chemicals break down the rubber. If you don't notice, the hose will eventually start to leak. If you don't notice a gas leak, your vehicle could catch fire from the heat in the engine compartment.

In addition, PTFE has a higher temperature resistance than rubber. So if your engine overheats, there's less chance that the heat will damage the hose. In addition to PTFE's high heat resistance, it also has a higher pressure rating than rubber. So if a system, such as the cooling system or power steering, fails and causes more pressure than it should, there's less chance that the PTFE hose will burst. The AN6 size can handle pressures up to 2,500 psi.

Finally, if you buy nylon braided or stainless steel hoses made with PTFE instead of rubber, your new hose will make your engine look more professional. If you're looking for strength but prefer the softer texture of black nylon, you don't have to worry - our nylon braided lines do have stainless steel - they're just covered in nylon.

SAE 100 R7 Thermoplastic Hydraulic Hose

Tube: PA (polyamide) Oil-resistant seamless thermoplastic elastomer tube.

Reinforcement: One layer of Braided high strength synthetic fibers.

Cover: Black high abrasion resistant polyurethane.

- Hose ID: 1/8 Inch to 1 inch

- Hose OD: 8.5mm to 32mm

- Temperature Range: -40°C to +100°C (-40°F to +212°F), intermittent 110°C.

- Application: Medium pressure hydraulic and pneumatic systems.

- Working Pressure: 1000PSI to 3,000 PSI

- Minimum Burst Pressure: 12,000 PSI

- Minimum Bend Radius: 1 Inch

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| SAE 100R7-02 | 1/8″ | 3.3 | 8.5 | 17.2 | 2494 | 69 | 9991 | 13 | 0.038 |

| SAE 100R7-03 | 3/16″ | 4.8 | 10.8 | 20.7 | 3002 | 83 | 11992 | 20 | 0.080 |

| SAE 100R7-04 | 1/4″ | 6.4 | 13.0 | 20.7 | 3002 | 83 | 11992 | 33 | 0.120 |

| SAE 100R7-05 | 5/16″ | 7.9 | 15.1 | 17.2 | 2494 | 69 | 9991 | 46 | 0.145 |

| SAE 100R7-06 | 3/8″ | 9.5 | 17.0 | 15.5 | 2248 | 62 | 9005 | 51 | 0.170 |

| SAE 100R7-08 | 1/2″ | 12.7 | 20.7 | 13.8 | 2001 | 55 | 8004 | 76 | 0.250 |

| SAE 100R7-10 | 5/8″ | 15.9 | 23.0 | 13.8 | 2001 | 55 | 8004 | 86 | 0.300 |

| SAE 100R7-12 | 3/4″ | 19.1 | 26.0 | 11.5 | 1668 | 45 | 6525 | 150 | 0.346 |

| SAE 100R7-16 | 1″ | 25.4 | 32.0 | 6.9 | 1001 | 28 | 4060 | 180 | 0.422 |

SAE 100R7 Thermplastic Dual Line Hydraulic Hose

Tube: PA (polyamide) Oil-resistant seamless thermoplastic elastomer tube.

Reinforcement: One layer of Braided high strength synthetic fibers.

Cover: Black high abrasion resistant polyurethane.

- Hose ID: 1/8 Inch to 1 inch

- Hose OD: 8.5mm to 32mm

- Temperature Range: -40°C to +100°C (-40°F to +212°F), intermittent 110°C.

- Application: Medium pressure hydraulic and pneumatic systems.

- Working Pressure:1015 PSI to 3248 PSI

- Burst Pressure: 4060 PSI to 12992 PSI

- Minimum Bend Radius: 1 Inch

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | ||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m |

| SNP-R7D02 | R7D-02 | 3.2 | 1/8" | 3.4-3.6 | 8.5 | 224 | 3248 | 896 | 12992 | 19 | 0.076 | 90-110 |

| SNP-R7D03 | R7D-03 | 4.8 | 3/16" | 4.6-5.4 | 10.8 | 224 | 3248 | 896 | 12992 | 19 | 0.160 | 90-110 |

| SNP-R7D04 | R7D-04 | 6.4 | 1/4" | 6.2-7.0 | 13.0 | 210 | 3045 | 840 | 12180 | 38 | 0.240 | 90-110 |

| SNP-R7D05 | R7D-05 | 7.9 | 5/16" | 7.7-8.5 | 15.1 | 175 | 2538 | 700 | 10150 | 44 | 0.290 | 90-110 |

| SNP-R7D06 | R7D-06 | 9.5 | 3/8" | 9.3-10.1 | 17.0 | 158 | 2291 | 632 | 9164 | 51 | 0.340 | 90-110 |

| SNP-R7D08 | R7D-08 | 12.7 | 1/2" | 12.3-13.5 | 20.7 | 158 | 2291 | 632 | 9164 | 76 | 0.500 | 90-110 |

| SNP-R7D10 | R7D-10 | 15.9 | 5/8" | 15.5-16.7 | 25.0 | 192 | 2784 | 768 | 11136 | 152 | 0.600 | 45-55 |

| SNP-R7D12 | R7D-12 | 19.1 | 3/4" | 18.6-19.8 | 26.0 | 88 | 1276 | 352 | 5104 | 127 | 0.692 | 45-55 |

| SNP-R7D16 | R7D-16 | 25.4 | 1" | 25.0-26.4 | 32.0 | 70 | 1015 | 280 | 4060 | 203 | 0.844 | 45-55 |

SAE 100R7 Thermoplastic Non-Conductive Hydraulic Hose

Tube: PA (polyamide) Oil-resistant seamless thermoplastic elastomer tube.

Reinforcement: One layer of Braided high strength synthetic fibers.

Cover: Orange non-conductive, highly abrasion-resistant polyurethane

- Hose ID: 1/8 Inch to 1 inch

- Hose OD: 8.5mm to 32mm

- Temperature Range: -40°C to +100°C (-40°F to +212°F), intermittent 110°C.

- Application: Medium pressure hydraulic and pneumatic systems.

- Working Pressure: 1015 PSI to 3248 PSI

- Burst Pressure: 4060 PSI to 12992 PSI

- Minimum Bend Radius: 1 Inch

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | ||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m |

| SNP-R7N02 | R7N-02 | 3.2 | 1/8" | 3.4-3.6 | 8.5 | 224 | 3248 | 896 | 12992 | 19 | 0.038 | 90-110 |

| SNP-R7N03 | R7N-03 | 4.8 | 3/16" | 4.6-5.4 | 10.8 | 224 | 3248 | 896 | 12992 | 19 | 0.080 | 90-110 |

| SNP-R7N04 | R7N-04 | 6.4 | 1/4" | 6.2-7.0 | 13 | 210 | 3045 | 840 | 12180 | 38 | 0.120 | 90-110 |

| SNP-R7N05 | R7N-05 | 7.9 | 5/16" | 7.7-8.5 | 15.1 | 175 | 2538 | 700 | 10150 | 44 | 0.145 | 90-110 |

| SNP-R7N06 | R7N-06 | 9.5 | 3/8" | 9.3-10.1 | 17.0 | 158 | 2291 | 632 | 9164 | 51 | 0.170 | 90-110 |

| SNP-R7N08 | R7N-08 | 12.7 | 1/2" | 12.3-13.5 | 20.7 | 158 | 2291 | 632 | 9164 | 76 | 0.250 | 90-110 |

| SNP-R7N10 | R7N-10 | 15.9 | 5/8" | 15.5-16.7 | 25.0 | 192 | 2784 | 768 | 11136 | 152 | 0.300 | 45-55 |

| SNP-R7N12 | R7N-12 | 19.1 | 3/4" | 18.6-19.8 | 26.0 | 88 | 1276 | 352 | 5104 | 127 | 0.346 | 45-55 |

| SNP-R7N16 | R7N-16 | 25.4 | 1" | 25.0-26.4 | 32.0 | 70 | 1015 | 280 | 4060 | 203 | 0.422 | 45-55 |

SAE 100 R8 High Pressure Thermoplastic Hydraulic Hoses

Tube: PA (polyamide) Oil-resistant seamless thermoplastic elastomer tube.

Reinforcement: Two layer of Braided high strength synthetic fibers.

Cover: Black high abrasion resistant polyurethane.

- Hose ID: 1/8 Inch to 1 inch

- Hose OD: 10.2mm to 34mm

- Temperature Range: -40°C to +100°C (-40°F to +212°F), intermittent 110°C.

- Application: Medium pressure hydraulic and pneumatic systems.

- Working Pressure: 1500 psi to 5000 PSI

- Minimum Burst Pressure: 20000 PSI

- Minimum Bend Radius: 1 Inch

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| SAE 100R8-02 | 1/8″ | 3.3 | 10.2 | 34.5 | 5003 | 138 | 20012 | 20 | 0.090 |

| SAE 100R8-03 | 3/16″ | 4.8 | 13.1 | 34.5 | 5003 | 138 | 20012 | 40 | 0.120 |

| SAE 100R8-04 | 1/4″ | 6.4 | 15.9 | 34.5 | 5003 | 138 | 20012 | 50 | 0.160 |

| SAE 100R8-05 | 5/16″ | 7.9 | 17.0 | 20.0 | 4350 | 120 | 17400 | 65 | 0.175 |

| SAE 100R8-06 | 3/8″ | 9.5 | 19.0 | 27.6 | 4002 | 110 | 16008 | 75 | 0.190 |

| SAE 100R8-08 | 1/2″ | 12.7 | 22.7 | 24.0 | 3480 | 95 | 13920 | 102 | 0.300 |

| SAE 100R8-10 | 5/8″ | 15.9 | 25.0 | 18.5 | 2683 | 74 | 10732 | 150 | 0.360 |

| SAE 100R8-12 | 3/4″ | 19.1 | 29.0 | 13.5 | 1958 | 54 | 7832 | 180 | 0.370 |

| SAE 100R8-16 | 1″ | 25.4 | 34.0 | 10.0 | 1450 | 40 | 5800 | 230 | 0.490 |

SAE 100R8 Thermoplastic Twin Line Hydraulic Hose

Tube: PA (polyamide) Oil-resistant seamless thermoplastic elastomer tube.

Reinforcement: Two layer of Braided high strength synthetic fibers.

Cover: Black high abrasion resistant polyurethane.

- Hose ID: 1/8 Inch to 1 inch

- Hose OD: 10.2mm to 34mm

- Temperature Range: -40°C to +100°C (-40°F to +212°F), intermittent 110°C.

- Application: Medium pressure hydraulic and pneumatic systems.

- Working Pressure: 1500 psi to 5000 PSI

- Minimum Burst Pressure: 20000 PSI

- Minimum Bend Radius: 1 Inch

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | ||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m |

| SNP-R8D02 | R8D-02 | 3.2 | 1/8" | 3.4-3.6 | 10.2 | 354 | 5133 | 1416 | 20532 | 20 | 0.18 | 90-110 |

| SNP-R8D03 | R8D-03 | 4.8 | 3/16" | 4.6-5.4 | 13.1 | 345 | 5003 | 1380 | 20010 | 40 | 0.240 | 90-110 |

| SNP-R8D04 | R8D-04 | 6.4 | 1/4" | 6.2-7.0 | 15.9 | 345 | 5003 | 1380 | 20010 | 50 | 0.320 | 90-110 |

| SNP-R8D05 | R8D-05 | 7.9 | 5/16" | 7.7-8.5 | 17.0 | 300 | 4350 | 1200 | 17400 | 65 | 0.350 | 90-110 |

| SNP-R8D06 | R8D-06 | 9.5 | 3/8" | 9.3-10.1 | 19.0 | 276 | 4002 | 1104 | 16008 | 75 | 0.380 | 90-110 |

| SNP-R8D08 | R8D-08 | 12.7 | 1/2" | 12.3-13.5 | 22.7 | 240 | 3480 | 960 | 13920 | 102 | 0.600 | 90-110 |

| SNP-R8D10 | R8D-10 | 15.9 | 5/8" | 15.5-16.7 | 25.0 | 185 | 2683 | 740 | 10730 | 150 | 0.720 | 45-55 |

| SNP-R8D12 | R8D-12 | 19.1 | 3/4" | 18.6-19.8 | 29.0 | 135 | 1958 | 540 | 7830 | 180 | 0.740 | 45-55 |

| SNP-R8D16 | R8D-16 | 25.4 | 1" | 25.0-26.4 | 34.0 | 100 | 1450 | 400 | 5800 | 230 | 0.980 | 45-55 |

SAE 100R8 Thermoplastic Non-Conductive Hydraulic Hose

Tube: PA (polyamide) Oil-resistant seamless thermoplastic elastomer tube.

Reinforcement: Two layer of Braided high strength synthetic fibers.

Cover: Orange non-conductive, highly abrasion-resistant polyurethane

- Hose ID: 1/8 Inch to 1 inch

- Hose OD: 10.2mm to 34mm

- Temperature Range: -40°C to +100°C (-40°F to +212°F), intermittent 110°C.

- Application: Medium pressure hydraulic and pneumatic systems.

- Working Pressure: 1500 psi to 5000 PSI

- Minimum Burst Pressure: 20000 PSI

- Minimum Bend Radius: 1 Inch

| Code | Size | Inside Diameter | Outside Diameter | Working Pressure | Bursting Pressure | Bend Radius | Weight | Length | ||||

| # | Dash | mm | Inch | mm | mm | bar | psi | bar | psi | mm | kgs/m | m |

| SNP-R8N02 | R8N-02 | 3.2 | 1/8" | 3.4-3.6 | 10.2 | 354 | 5133 | 1416 | 20532 | 20 | 0.09 | 90-110 |

| SNP-R8N03 | R8N-03 | 4.8 | 3/16" | 4.6-5.4 | 13.1 | 345 | 5003 | 1380 | 20010 | 40 | 0.120 | 90-110 |

| SNP-R8N04 | R8N-04 | 6.4 | 1/4" | 6.2-7.0 | 15.9 | 345 | 5003 | 1380 | 20010 | 50 | 0.160 | 90-110 |

| SNP-R8N05 | R8N-05 | 7.9 | 5/16" | 7.7-8.5 | 17.0 | 300 | 4350 | 1200 | 17400 | 65 | 0.175 | 90-110 |

| SNP-R8N06 | R8N-06 | 9.5 | 3/8" | 9.3-10.1 | 19.0 | 276 | 4002 | 1104 | 16008 | 75 | 0.190 | 90-110 |

| SNP-R8N08 | R8N-08 | 12.7 | 1/2" | 12.3-13.5 | 22.7 | 240 | 3480 | 960 | 13920 | 102 | 0.300 | 90-110 |

| SNP-R8N10 | R8N-10 | 15.9 | 5/8" | 15.5-16.7 | 25.0 | 185 | 2683 | 740 | 10730 | 150 | 0.360 | 45-55 |

| SNP-R8N12 | R8N-12 | 19.1 | 3/4" | 18.6-19.8 | 29.0 | 135 | 1958 | 540 | 7830 | 180 | 0.370 | 45-55 |

| SNP-R8N16 | R8N-16 | 25.4 | 1" | 25.0-26.4 | 34.0 | 100 | 1450 | 400 | 5800 | 230 | 0.490 | 45-55 |

Why Choose Sinopulse

We offer a range of custom hose solutions designed to meet your specific requirements, providing optimal performance for any application. We specialize in providing standard and custom hose solutions designed to meet your specific needs. Our unwavering dedication to quality, innovation and precision guarantees you the most reliable and high-performance products for a wide range of industrial applications

Our advanced manufacturing techniques guarantee precision and durability, producing hoses that excel in demanding environments.

Each product is rigorously inspected by skilled professionals, ensuring that each hose meets our high standards for reliability and safety.

Sinopulse thermoplastic hoses are made with rigorous testing and 100% virgin raw materials for unmatched durability and reliability.

We offer conductive and non-conductive thermoplastic hoses that resist electrical current to meet your specific needs. We also have airless spray hoses that can be used at high pressures in painting and sandblasting applications. All hose add-ons and accessories are also available, including thermoplastic hose fittings, connectors, and more. All of our thermoplastic hydraulic hoses meet or exceed SAE performance requirements and are specifically designed to deliver petroleum, water-based, and synthetic hydraulic fluids for a wide range of industrial, power, agricultural, and construction machinery. For custom hose sizes or application-specific adjustments, buy your thermoplastic hose from us today! Let us find you the best hose for your application at an affordable price.