Factory Gallery

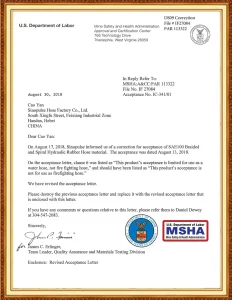

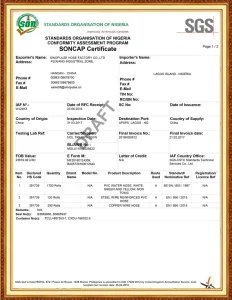

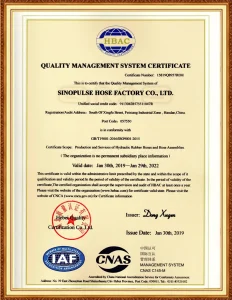

Sinopulse Hose Factory Co., Ltd has 20 years of manufacturing and exporting experience in hydraulic hose, industrial hose, and fittings since 2011. Our factory has passed ISO 9001 and MSHA certificates. The Brand Sinopulse is sold in many countries worldwide and has helped customers increase their market share in the local market.

The factory covers more than 78,000 square meters and includes a rubber mixing workshop, soft mandrill workshop, hard mandrill workshop, non-mandrill workshop, and office building. 60 production lines and 120 sets CNC machines, Our factory is capable of producing 80,000 meters of hose and 10 million fittings per day. Shipping the Hose and fittings to More than 200 clients from 80 countries and ares.

Factory Qualification Certification

(ONE) IN THE LABORATORY, BEFORE HOSE PRODUCTION

1) After finishing the rubber sheet in our laboratory, we test the rubber hardness and tensile. According to our requirement in Shore A 82-85, the rubber tensile both of the inner tube of hydraulic hoses and Outside cover rubber are high than other factories, If interested in our rubber material tensile, we may send you our test record and video, or you can visit our factory then we will show you how we test ubber material tensile

2) After we buy the steel wire used in the hose reinforcement layer from the top steel wire factories in China, we will test the wire tensile. The tensile must be within our required tolerance to ensure the working pressure and burst pressure.

3)We make vulcanization test for inner tube rubber and out cover rubber in our laboratory, to ssure the rubber we used vulcanization is under our control in 5 minutes, 10 minutes, half an hour, and one hour above.

4) We also check how much adhesive pulling power is between the rubber, to ensure adhension in hoses we produced.

after

Hose Raw Material Laboratory

The Raw Material test of hoses will make the Sinopulse hoses more resistant to high pressure, aging, wear and high pulse, longer service life and better connection with hydraulic fittings

(TWO) IN THE WORKSHOP, DURING HOSE PRODUCTION

1) Prepare a soft or steel mandrill on the previous day and dry the mandrill to ensure it separates well from the inner rubber tube but does not hurt the inner tube of hoses.

2) We adjust steel joint machines every week. We test the steel wire length difference according to the tolerance of standard to assure the same length before braiding the machine, so that we can avoid wire joints in the wire braid process to reduce the probability of hose leakage.

3) We use an advanced cold feeder extruder controlled by a PLC computer. Cold feeder extruder has more power to extrude rubber inner tube in good shape.

4) After finishing extruding the inner tube, we are required to make it recover the previous shape at normal temperature. After at least 8 hours, we begin to put it in the colding machine at -30C for the braiding machine.

5) In Germany's technology braiding machines ensure the braid reinforcement is more compact and in good shape, higher than standard. The finishing of the hydraulic hoses is in perfect shape.

6) Our standard requires pitch and steel wire distance in braiding and spiral machines, to ensure the steel wire angle is in control. and our meet the steel wire angle standard of most countries and also meet the relatively strict European standards.

7) After braiding or spiraling, we will carry out a series of production processes such as outer rubber extrusion, word film, water cloth wrapping, vulcanization, water cloth dewatering, etc. Each process has strict production records, inner and outer diameter control, and quality control. We will cut and classify the hoses that do not meet the quality standards into the secondary quality warehouse and will not sell them to you.

Hydraulic Hose Production Process

(THREE) AFTER PRODUCTION, BEFORE SHIPMENT.

Hydraulic hose factory three tests: Working pressure test, Burst pressure test, and Hose Impulse Testing

1) After finishing the hoses, we test proof pressure for60s, checking any possible leak or defective point of rubber hoses before shipping to our customers.

2) The burst pressure of hydraulic hoses must reach four times the working pressure.

3) The impulse testing must be above 200000 circles for braided hydraulic hoses and 400000 circles for spiral hydraulic hoses.

Before leaving the factory, all hydraulic hose is tested three times. Ensure trouble-free installation and operation of your new hose.

Partner with Sinopulse – Your Private Label Manufacturer for Industrial, Hydraulic, Thermoplastic, PVC, and Specialty Hoses

Sinopulse offers private label hydraulic and industrial hoses for global distributors. We manufacture and supply a wide range of low, medium, and high-pressure hoses, including rubber, thermoplastic, and PVC hoses that meet or exceed international standards.

With a highly skilled engineering team and advanced hose manufacturing capabilities in China, we are well-positioned to respond quickly to any custom design or production request.

Excellence in Customization Since 2011

At Sinopulse, every project is unique.

We listen to your needs and design tailored solutions that match your requirements.

Our mission is to provide problem-solving custom hose solutions that ensure optimal performance for your specific application.

High-Quality Custom Hydraulic and Industrial Hose Manufacturer

Since 2001, Sinopulse has built a reputation for reliable and competitively priced hose products.

Our knowledgeable, experienced, and customer-focused team is committed to quality.

With strong production capacity, fast lead times, and consistent product performance, we support distributors and hose assembly professionals who drive the industry forward.

Established in 2001 and upgraded to a leading hose manufacturing facility in 2011, Sinopulse is an expert in providing industrial and hydraulic hoses for OEMs across diverse industries.

Certified to multiple international standards, we ensure strict compliance with industry regulations.

Besides supplying components and fittings to OEMs, we offer fully customized hose solutions for oilfield and industrial equipment providers.

Our products are 100% customizable, and we collaborate closely with clients to meet their precise needs.

Quality Assurance

-

State-of-the-art Testing Equipment for consistent performance and durability

-

Responsive Customer Service: Work directly with professionals for fast, efficient support

-

Certifications: ISO 9001:2015, UL, CSA

-

Hose & Fittings with high pulse resistance and pressure durability

-

Premium Products: Competitive pricing with first-class quality and service

-

Innovation Focus: Dedicated to the design, development, production, and distribution of fluid power transmission products

-

Industry Expertise: Customized solutions for every sector

-

Technology Investment: Fully equipped modern factory and machinery to maintain a competitive edge

Product Range:

Hydraulic Hoses

Beyond standard hoses, Sinopulse offers a wide range of custom solutions.

Our newly launched ultra-flexible spiral hose series—1SNK, 1SCK, 2SNK, and 2SCK—are designed for demanding high-pressure applications.

These hoses exceed SAE 100R12, 100R13, 100R15, and ISO 18752-CC standards.

With up to 40% improved bend radius and 30% less bending force, these hoses offer outstanding ergonomics and safety advantages during equipment assembly.

Industrial Hoses

Sinopulse manufactures a full range of industrial hoses using various compounds and reinforcement techniques for a wide spectrum of markets and applications.

From low-pressure water hoses to hoses capable of transporting aggressive chemicals, we deliver dependable and consistent performance.

Customization options include branding and color coding.

Our industrial hoses are ideal for low-pressure applications in automotive, injection molding, paper mills, and general industry.

We also manufacture:

-

Sewer Jetting Hoses: Made from rubber and thermoplastics with excellent service life

-

Concrete Pumping Hoses: Highly abrasion-resistant, flexible, and long-lasting, ideal for boom and end hoses in tough environments

-

Sandblasting Hoses: Superior abrasion resistance for extended use

-

Oil Hoses: High flexibility and easy handling across all petroleum applications

PVC Hoses

With over 20 years of experience in PVC hose R&D, manufacturing, and export, our PVC hose products serve a wide range of industries.

Thermoplastic Hoses

Designed for hydraulic systems, trucks, and specialized equipment, our thermoplastic hoses offer exceptional versatility and durability.

Compliant with and exceeding SAE 100R7, R8, and R18 standards, these lightweight hoses offer multiple benefits, including:

-

Dual/triple-layer bonded designs

-

Superior abrasion and UV resistance

-

PA inner tubes with oil-resistant PU outer covers for excellent all-around performance

Hose Solutions

Sinopulse offers hydraulic and industrial hoses that can be customized to replace branded equivalents.

Our hoses are versatile and durable, suitable for hydraulic fluids, oil, irrigation, food delivery, chemical transport, construction, and more.

They are designed to handle fluids, dry materials, chemicals, and various substances throughout all processing stages.

We supply hoses for industries such as:

-

Heavy Industry

-

Construction

-

Manufacturing

-

Beverage

-

Agriculture

-

Mining

-

Infrastructure

Our extensive, high-tech product range meets diverse needs with consistent quality.

Industrial Reach

Sinopulse proudly serves clients in over 150+countries, including both large and small entities across:

-

Government sectors

-

Resources

-

Agriculture

-

Industrial manufacturing

-

Marine

-

Chemical processing

-

Waste management

-

Railways

-

Oil and gas

-

Offshore and onshore manufacturing

Our goal is to create more value for more gloable customers! We have ability for hose research and design. If any custom need of hoses, reach us now !

So please rest assured to use, Sinopulse hose is trustworthy!