Hydraulic Hose

Hydraulic hose is specifically designed to convey hydraulic fluid within a hydraulic system.

Hydraulic hoses are used in a wide range of hydraulic equipment, including construction machinery, the coal chemical industry, agricultural machinery, metallurgy, mining, petroleum, ships, marine, and heavy industrial equipment. They play a vital role in mining, agriculture, forestry, and construction.

Sinopulse is a 20-year-experienced hydraulic hose factory and manufacturer. The hydraulic hoses we produce meet and exceed SAE and DIN EN standards, such as SAE R1AT, SAE R2AT, SAE R16, EN853 2SN, EN853 1SN, etc.

Check our full range of hydraulic hose products here.

Factory And Production Capabilities

Our hose factory covers more than 45000㎡, includes a rubber mixing workshop, wire workshop, mandrill workshop, hose braided workshop, hose spiral workshop, rubber extrusion workshop, hose testing workshop and a hose R&D building. From hose rubber production to wire braiding and spiral to final packaging, every process is done in our factory. Every production process has strict quality control to ensure you receive high-quality hydraulic hose.

Factory 86 hydraulic hose production lines can daily output of up to 100,000 meters. So our fast production and on-time delivery could reduce equipment downtime and save you costs.

Quality Standards and Testing

As a professional hydraulic hose manufacturer, we know the importance of hose quality. Our hydraulic hoses meet or exceeded ISO9001:2008, MSHA, SGS, FDA, and GOST standards to any market needs. At the same time, there is strict production process quality management and finished hose testing process, including pulse test, pressure test, burst test, etc.

And Sinopulse hoses and fittings are manufactured to the same superior performance standards and specifications as products from famous hydraulic hose manufacturers such as Parker, Gates, and Eaton. They are our goal and motivation.

Global Market and One-stop Solutions

Our products are exported to the United States, Europe, Brazil, Africa, and other countries and are highly praised by customers. With our excellent engineering staff and advanced hose manufacturing capabilities, we can respond quickly to any questions or requests for custom design production.

Welcome to cooperate with us, become our distributor, or build your own hydraulic hose. For bulk orders, we support one-stop solution services for customization and R&D of hydraulic hoses and fittings! Contact Sinopulse now

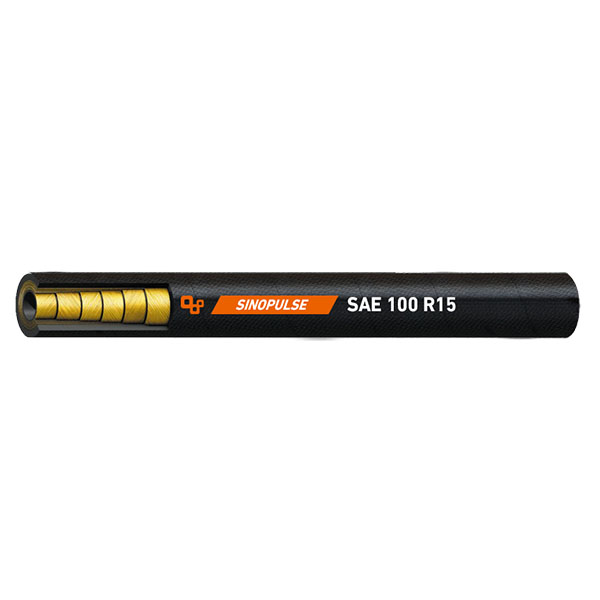

Supply 3/8 inch to 2 inch sizes spiral hoses with working pressure up to 6000 psi. Custom length, good quality, and bulk quantities have discounted prices. Wear-resistant, low-temperature, and high-temperature hose options are available

Product including: EN 856 4SP, 4SH. SAE 100R12, R13, R15

Supply 3/16 inch to 2 inch sizes braided hoses with working pressure up to 6000 psi.Custom lengths, good quality, and bulk quantities have discounted prices. Super flexible, wear-resistant, low-temperature, and high-temperature hose options available

Product including: SAE 100R1AT, R2AT, R16, R17, 1SC, 2SC, EN853 1SN, 2SN

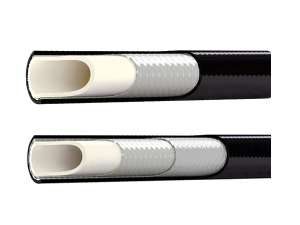

Supply 3/16 inch to 1 inch sizes textile braided hoses with working pressure up to 1500 psi.The cover smooth or wrapped is optional, mostly used in medium- and low-pressure hydraulic systems. custom length and bulk quantities have discounted prices.

Product including: SAE 100R3, R6, 2TE, 3TE

Supply chemical, temperature, and moisture resistant thermoplastic hoses, available in sizes from 1/8 inch to 1 inch and pressures up to 5000 psi.Available in standard, anti-static, and twin line hose options. Support customized color, logo and packaging

Product including: SAE 100R7 and SAE 100R8

Supply PTFE hose, corrosion resistance, high temperature resistance and low friction improve safety in use. 1/8 inch to 1 1/2 inch size is avaliable. Working pressure up to 4000 psi. custom length and ptfe tube type. bulk quantities have discounted prices.

Product including:SAE 100 R14

Supply specialty hose, such as R4 suction and return hose, R5 braided textile cover hose, pressure washer hose or other specialty hose for your need. We can produce all the special hydraulic hoses you need.

Supply high-quality stainless steel metal hose blanks, mesh sleeves, spiral hose, continuous ring corrugated hose, ring corrugated hose. Multi-layer mesh, thickened and ultra flexible options available.

Supply 1/4" - 1/2" ultra high pressure hydraulic hose, and it working pressure up to 16000psi. mainly used for waterjet cutting, cleaning of tubes, and heat-exchangers. Bulk quantities have discounted prices.

About Sinopulse Hydraulic hoses

Sinopulse is a leading hydraulic hose manufacturer with 15 years of experience in the hydraulic industry. We offer a full range of hydraulic hoses. Our hydraulic hoses are designed for harsh environments and cover applications in construction, agriculture, mining, and industrial.

Our product line includes standard hydraulic hoses, high-pressure hoses, high-temperature hoses, abrasion-resistant hoses, and specialty hydraulic hoses, available in various pressure ratings, materials to meet any hydraulic needs.

We produce 100,000 hydraulic fittings and 80,000 meters of hydraulic hose daily, ensuring fast delivery to you.

Sinopulse hydraulic hoses use premium materials and advanced manufacturing processes to ensure superior durability, flexibility, and pressure stability. Each hose features an oil-resistant inner tube, a high-strength steel wire or textile reinforcement layer, and a weather-resistant and abrasion-resistant protective outer layer.

All Sinopulse hoses are designed to meet or exceed SAE, EN, and international industry standards, providing consistent performance and extended service life even under the most demanding conditions.

Are you looking for China hydraulic hose manufacturers, Sinopulse, as a professional China hydraulic hose manufacturer with own factory, provides high quality hydraulic hose products with competitive price to the world. All hoses are manufactured in our Sinopulse hose factory in China, one of the largest and most professional hose manufacturing factories in China.

Sinopulse Hydraulic hoses applications

Hydraulic hoses can safely transport fluids within the hydraulic system, and due to their flexibility, the required installation space is extremely small.

The Sinopulse product range includes hoses made of rubber, elastomers and thermoplastic plastics. Their reinforcing materials include fabrics, steel wire braiding or multi-layer spiral steel wire inserts. These hoses can withstand pressures up to 600 bar. These hoses are suitable for numerous mobile and fixed hydraulic applications. The hydraulic hoses we produce are widely used in various industries. They are primarily used in construction, road, transport, and agricultural machinery. We use components manufactured by renowned companies, guaranteeing the highest quality and durability.

Sinopulse innovates, designs and manufactures custom fluid transfer solutions for many well-known OEM brands. Our hoses are used in the global mobile and off-highway hydraulic markets. We can meet even the most stringent OEM regulations in a variety of industries, such as those listed below.

Agriculture

Construction

Cranes, Lifts,Utility

Forestry & Landscaping

Marine

Material Handling Mining/Drilling

Pressure Cleaning

Transportation/RVs

High-quality hydraulic hoses China

The product range includes a variety of design and material combinations of hydraulic hoses, suitable for all applications of both fixed and mobile hydraulic systems. All hydraulic hoses used for low-pressure, medium-pressure and high-pressure applications, as well as suction hoses, are made of high-quality materials and have undergone extensive testing.

Sinopulse hydraulic hose types include:

SAE 100 R1, SAE 100 R2, SAE 100 R16, SAE 100 R17, SAE 100R19, EN 853 1SN, EN 853 2SN, EN 857 1SC, EN 856 2SC; ISO 1436 1SN, ISO 1436 2SN, ISO 11237 1SC, ISO 1437 2SC, etc.

The braided hydraulic hose is made of steel wires braided together. The steel wires are alternately braid in different directions around the inner rubber tube of the hose to form the braided reinforcement layer.

Steel braided hoses have single or double steel wire braided reinforcement. They are used in automobiles, engineering equipment, oil extraction, machinery manufacturing.

We produce braided hydraulic hose that meets or exceed standards above. We also supply super-wear-resistant series, high-temperature series, low-temperature series, super-flexible series, and other braided hoses to meet your needs.

SAE 100 R12, SAE 100 R13, SAE 100 R15, EN 856 4SP, EN 856 4SH

Steel wire spiral hoses withstand higher pressures. and they are available in 4- and 6-layer steel wire spiral reinforcement. As a professional hydraulic factory, we provide custom sizes and other hose solution you need.

The inner reinforcement layer of the spiral hydraulic hose is steel wires. This structure can have up to six layers and is suitable for high pressure up to 500 bar.

SAE 100 R3, SAE 100 R6, EN 854 2TE, EN 854 3TE.

Textile braided hydraulic hoses withstand lower pressures but are more flexible. They are used in low-pressure hydraulic systems to transport petroleum-based hydraulic fluids.

The textile hydraulic hose uses high-tech synthetic fibers such as aramid to achieve maximum pressure stability. These hoses are flexible and lightweight and are suitable for low pressure ranging up to 100 bar.

PTFE Hose:

SAE 100 R14

PTFE hose's PTFE inner tube material offers superior corrosion and chemical resistance and high temperatures. It's used in fluid compatibility, high temperatures, and corrosive-environment industries. We can customize PTFE tubes to your specifications, including smooth and convoluted PTFE hose.

=SAE 100 R7, SAE 100 R8, EN 855 R7, EN 855 R8

=Thermoplastic hoses are made from polyurethane, polyolefin, or thermoplastic elastomer materials. This type of hose is UV-resistant and abrasion-resistant. We can produce these hoses to meet your specific needs, including single or double line, color, reinforcement material (metal or fiber braided),and anti-static.=

Hydraulic hoses made of thermoplastic or elastomer materials possess excellent oil resistance and aging resistance, and can maintain flexibility even at extremely low temperatures as low as -40°C. Other advantages of thermoplastic hoses include light weight, strong chemical corrosion resistance, and flexibility. Hoses made of thermoplastic and elastomer materials both have extremely strong resistance to ultraviolet radiation and high impact strength.

=

Metal Hose is made of 314 or 316 stainless steel, offering flexibility, durability, and anti high temperatures and pressures. Metal hydraulic hoses are particularly suitable for need flexible and vibration applications.

SAE 100 R5: This hose is a low-pressure hydraulic rubber hose. It's special in its steel wire braided reinforcement layer with a textile braided cover. so it has excellent abrasion resistance and flexibility. We also offer a high-temperature resistant R5 hose series. Please contact us if you need.

SAE 100 R4 Hose: The SAE 100 R4 hose is a spiral hose primarily used for the suction and return of hydraulic fluids, mineral oils, and fuels. Because of the need for suction, its reinforcement consists of single or multiple layers of braided textile fabric with a steel wire helix in the hose to prevent deformation during suction.

Why Choose Sinopulse as your reliable hose manufacturer

Sinopulse hose factory is a leading supplier of high-pressure hydraulic hose, with over 20 years of experience in the hydraulic hose industry. Sinopulse offers a hydraulic hose option for most applications from industrial to marine, with high-pressure and high-temperature hydraulic hose products available in a wide range of pressure ratings, materials, and styles. Sinopulse’s quick production of high-quality hydraulic hose ensures the right hose to match any specification is in stock and ready for delivery.

Tested hydraulic hose

Every hydraulic hose manufactured by Sinopulse undergoes pulse and pressure testing. Only hoses that pass these tests are shipped to customers.

If you have higher pressure or temperature requirements for your hoses, we can customize them and provide samples for testing to meet your specific needs.

As a reliable hydraulic hose manufacturer, we have 86 production lines, capable of producing 8,000 meters of hose and 100,000 hydraulic fittings daily, ensuring on-time delivery.

one-stop hose and fittings solution service

In addition to hydraulic hoses, we also offer a wide range of hydraulic hose assemblies, hydraulic hose fittings, adapters, quick couplings, hose protections and crimping machines. You can find everything you need here to ensure your hydraulic system is leak-free, reduce equipment downtime, and lower maintenance costs.

Sinopulse Factory Advantages

Sinopulse has its own testing laboratory, rubber raw material production factory, customized research and development center, and quick production line, which can quickly and reliably meet the requirements of each customer.

-

Fast delivery

With 80000 meters of hose daily output, we guarantee the fastest production and delivery capability.

-

Strict hose quality control

The hydraulic hoses and hose assemblies should be fully tested on our own test lab. and all hoses we produce meet ISO9001:2015 and MSHA.

-

Customer services

We are 7/24H service to help you choose hydraulic hose suitable for your application.

Sinopulse has over 20 years of experience in the hydraulic industry, and our hydraulic fluid experts can provide advice to help you choose the most suitable hydraulic hose. Furthermore, you can communicate with our staff online or through a factory visit to receive advice on hydraulic hose selection and installation.

-

Custom hose

The production of hydraulic hose is carried out in Sinopulse's own factory, meeting various demands.

-

Hose manufactured in bulk

The hose production line composed of advanced production equipment from Germany and Italy enables us to quickly manufacture a variety of hoses including hydraulic, high-pressure, PTFE and industrial hoses, covering both small and large batches. We are committed to providing the highest process reliability and products that meet quality standards, and customizing storage and logistics processes according to your individual needs.

-

Factory-based customized hose assembly production, with efficient processes

Through the Sinopulse hose compression factory production, you can customize the production of hydraulic hoses and other components according to your needs.

Provide the required assemblies as per demand

Quick production of hose options

The assemblies are directly used, without storage costs

-

Using ID cards for hose production management

For each hydraulic hose pipeline production process, a production process quality inspection form needs to be filled out. We call it an ID card and give it a unique identifier. This ensures the quality of each hydraulic hose production process and enables the replication of the corresponding products. This allows us to guarantee the quality of the produced hydraulic hoses.

Choose Sinopulse as your China Hose & Fitting Specialist.

Contact us today to learn more about our hydraulic hoses and to send an inquiry.

Download PDF Hose Catalog

we supply the safest, most durable, and efficient industrial hydraulic hoses, couplings, fittings, and equipment. we supply hydraulic solution, from low-pressure to ultra-high pressure hose assemblies, application-specific systems to versatile fluid compatibility. Recognized to meet MSHA and ISO international standards and quality certifications. meanwhile we alse custom hose assemblies to improve your onsite safety, reduce downtime, and increase your productivity. contact us now!

- Bulk hydraulic hoses can be cut to a desired length, and compatible hose fittings can be attached to the ends of the hoses to create custom hydraulic hose assemblies.

- Hydraulic hose assemblies come with fittings installed on both ends for connecting the hoses to compatible equipment.

- Hydraulic hose protections prevent hydraulic hoses to pressure or fluid from escaping during a hose failure.

Learn more in our guide: Hydraulic Hose vs Rubber Hose.

Hot Products

Related Product

FAQ of hydraulic hose

What is hydraulic hoses?

Hydraulic hoses are key components to convey hydraulic fluid between components in hydraulic systems.

What is hydraulic hose structure?

Hydraulic hose construction with 3 layers. The inner layer is in direct contact with hydraulic fluid. So, they need to be oil-resistant. The reinforcement layer is made up of steel or textile of high tensile strength. This layer provides the necessary strength for high-pressure applications. The reinforcements have a spiral or braided design. The outer cover of the hose acts as a protective layer and should be anti-abrasive and resistant to oils, fuels and atmospheric conditions.

What are hydraulic hoses used for?

Hydraulic hose is used to allow hydraulic fluid to flow from one component to another

High-pressure hydraulic hoses are an excellent choice for use in industrial machinery, such as machine tools, cranes, forklifts, and construction equipment. These hoses are also used in the transport of liquids and gases at high pressures, in high-pressure cleaning processes, in food processing equipment, and in refrigeration equipment. Furthermore, these hoses are suitable for use in control systems, such as liquid or gas flow management. In conclusion, high-pressure hydraulic hoses are a versatile and reliable tool that can be used in a variety of applications.

What are hydraulic hoses materials?

Hydraulic hoses are made from many materials, including rubber, thermoplastics, and metal.

What hose diameter should I choose?

Selecting the appropriate hydraulic hose diameter is extremely important. Too small a hose diameter can cause the oil in the hydraulic system to heat up . We recommend selecting the inner diameter based on information about the oil flow. In short, the recommended diameter is DN = inner diameter of the hydraulic hose.

Are all Hydraulic hoses high-pressure?

No, there are not only high-pressure hydraulic hose but also low-pressure hydraulic hoses for different applications.

Low-pressure hoses handle less than 250 PSI, medium up to 3,000 PSI, and high-pressure between 3,000-6,000 PSI

How do I choose a hydraulic hose?

Choosing the right hydraulic hose is no easy task. First, you need to confirm the type of fluid passing through the hose. You also need to understand the working environment of your project, which determines the pressure and temperature range of the hydraulic hose. Then, confirm the size and length of the hose. The softness and service life of the hose are also within your considerations. Finally, if you are using hydraulic assemblies, you need to confirm ends and couplings type. in this way you can attach hose more easily. If you still have difficulty choosing a hydraulic hose, consulting a professional hydraulic hose manufacturer would be better.

How to properly crimp hydraulic hose assembly

Before you can correctly crimp the hydraulic pipe, you need to confirm a lot of information. First, confirm whether your hydraulic connector is compatible with the hydraulic pipe. Then measure the inner diameter of the hose to confirm that the size of the hose to be crimped is correct, and confirm that the material of the replacement hose is consistent with the old hose. After all these are confirmed, use a professional hose crimping machine to crimp. You set the relevant parameters and molds of the crimping machine, click Start, and the crimping machine begins to crimp according to the settings. The last crimped hose needs to be checked to ensure that the crimping is appropriate and there is no leakage. Then you can install this hydraulic pipe assembly on your equipment.

Top Hydraulic Hose Manufacturers in the World:

There are many excellent hydraulic hose manufacturers worldwide, such as

- Parker

- Sinopulse

- Gates

- Eaton

- Manuli Hydraulics

- Alfagomma Group

- RYCO Hydraulics

- SEMPERIT

- Bridgestone

- PIRTEK

You may not be familiar with the name of a manufacturer like Sinopulse. Sinopulse is a leading hydraulic hose manufacturer in China. Compared to other famous hose manufacturers, Sinopulse offers comparable quality, lower prices, and comprehensive service. They earn more and more recognition from world hydraulic hose customers.

Why Choose China Hydraulic Hose Factory?

The global hydraulic hose industry continues to expand. Numerous manufacturers have emerged worldwide, and Chinese hydraulic hose factories, with their multiple industry advantages, are also increasingly emerging. The Chinese hydraulic hose industry is increasing rapidly, China has a stable society, a large population, and affordable raw materials, enabling it has long-term cost advantages.

And China's technological development and professional hose making machines enable efficient hose production and delivery

That’s why Chinese hydraulic hose factories are one of the best choices for global customers.

Where to find the best wholesale and custom hydraulic hose factory in China

There are many ways to find a suitable China hydraulic hose manufacturer. First of all, you can attend hydraulic hose related exhibitions. Professional Chinese hydraulic hose manufacturers will participate in engineering equipment exhibitions and agricultural machinery exhibitions. Go to view China's online B2B platforms is also a good way to find them, such as Alibaba, Made in China and other platforms. If do not have any purchase hydraulic hose experience in China, you could find a professional purchasing company to help you buy hydraulic hose, because they understand the Chinese market rules better. What's more, you can also find them by searching for "Chinese hydraulic hose manufacturers" through social media LinkedIn, Facebook, Google, Bing, etc.

To view top 10 china hydraulic hose manufacturer, click here!

Hydraulic Hose Manufacturing Process

Choose Sinopulse for your hydraulic hoses manufacturer

Sinopulse is one of the leading hydraulic hose manufacturers in China. We are committed to providing the best hydraulic hose for your hydraulic projects, low budget machines and bring you an incredible hydraulic hose experience.

Sinopulse is a professional manufacturer of hydraulic hose, the factory covers an area of 45,000 square metres, 200+ employees, more than 10 engineers, including 5 senior engineers, the company has strong technical force, excellent tooling equipment, complete testing equipment, advanced production technology, and a perfect quality management system.(view Sinopulse factory)

Sinopulse offers durable hoses. Our hydraulic hoses are made of quality rubber materials that can withstand harsh working conditions and provide optimum performance.

Our hydraulic hoses are made from rubber materials that can withstand harsh working conditions and deliver optimal performance. We offer a wide range of hydraulic hoses, so you can flexibly choose the required specifications, lengths, thicknesses and diameters. We also offer customised printing services

With professional experience in manufacturing and selling hydraulic hoses, we keep abreast of the latest developments in hydraulic hose technology and provide comprehensive solutions for a wide range of industries.(view how Sinopulse hydraulic hose manufactured)

We are committed to providing quality products at competitive prices, and we endeavour to do so at the best possible price without compromising on quality!

Sinopulse manufactured all types of hydraulic hoses and fittings

Sinopulse high-pressure, high-temperature hydraulic hose features three-layer construction to ensure strength, flexibility, and proper pressure maintenance. Flexible, hydraulic-oil-resistant inner cores, steel or fabric mesh reinforcement layers and protective outer cover are all part of Sinopulse’s hose quality. All Sinopulse Hydraulics hoses meet or exceed SAE specifications.

- High-pressure Braided Hydraulic Hose

- High-pressure Spiral hydraulic hose

- Low-pressure textile braided hydraulic hose

- Thermoplastic Hose

- Specialty Hose

- Hose Protection Sleeve

- Hydraulic Hose Fittings

- hydraulic hose adapters

- quick couplers

- hydraulic hose crimping machine

Known for our advanced hose manufacturing capabilities, technical excellence, and friendly customer service, we are large enough to be a leader in the fluid power industry, yet small enough to be flexible, responsive, and proactive. We are ready to help with your most challenging applications, crafting individualized products and solutions for your specific needs. Not to mention, we have a 100% on-time delivery rate.

Sinopulse innovates, engineers and manufactures custom fluid conveyance solutions for many well-known OEM brands. Our hoses are hard at work throughout mobile and off-highway hydraulic markets around the world. We can satisfy even the strictest OEM regulations in various industries.

Each type of hose in our factory undergoes meticulous testing to ensure it meets our exact standards. With ISO 9001:2015 certification, we're committed to delivering excellence in every order. You can count on us for superior quality hose, backed by thorough quality checks on every purchase.

From the moment you connect with us, our dedicated team will provide personalized support and guidance. Whether you have questions about our products, need assistance with an order, or require technical expertise, we're here to help!

Expertise

All hoses are manufactured at our Sinopulse hose factory in China, one of the largest and most professional hose manufacturing facilities in the world. With our excellent engineering staff and world-class hose manufacturing capabilities, we can respond quickly to any questions or requests for custom design production.

Quality

Sinopulse's manufacturing processes are ISO 14001 certified to ensure an effective environmental management system, as well as ISO 9001, ISO 17025 and ISO 27001 certified to protect the health and safety of employees, and IATF 16949 certified to ensure quality management of automotive products.

Professional Factory

The factory covers an area of more than 45,000㎡ and has nearly 200 employees, supporting a variety of hose production - hydraulic, PVC, thermoplastic and industrial hoses, producing Sinopulse's leading hoses and private label products. R&D and strict quality control support every area of our production.

World Wide

We have distribution centers across the U.S., in Canada, Africa, Europe, South Asia, and South America.

Various Industries

In building, construction, mining, agriculture, transportation, food and other market sectors that require hydraulic and industrial hoses, our quality products meet and exceed all industry standards.

We are a leading hydraulic hose manufacturer in China, if you are looking for hydraulic hose, hydraulic hose couplings, industrial hose and other hose related products.

Sinopulse hose products feature the highest quality and superior performance to maximize customer productivity.

As one of the global hose experts, Sinopulse explores novel technologies in the hose industry and serves all consumers with superior quality.

If you are looking for professional hydraulic hose and industrial hose manufacturers, Sinopulse is your best choice. We offer better wholesale hydraulic hoses and best solutions to help you with your hydraulic projects. Feel free to contact us anytime.