Spiral Hydraulic Hose

Wire Spiral Hydraulic Hoses is ultra high pressure hoses used to transmit high pressure hydraulic power. It is designed to withstand high pressure and transmit fluid power, and has strong pressure endurance and durability. It is usually spirally reinforced with multiple layers of steel wire and wrapped in synthetic rubber material to achieve efficient hydraulic transmission in hydraulic systems in engineering, agriculture, industry and other fields, while adapting to various temperatures and environmental conditions. With Sinopulse four-spiral and six-spiral hoses, you can trust the quality and performance, making it an ideal choice for industries that require reliable and durable solutions to meet demanding application requirements, to meet your high-pressure hose needs

Very high-pressure applications used for petroleum-based hydraulic fluids

Tube: High-strength synthetic rubber.

Reinforcement: Four spiral layers of high-strength steel wire.

Cover: Anti-abrasive synthetic rubber, resistant to oils, fuels and atmospheric conditions

Very high-pressure, pulsating applications used for petroleum-based hydraulic fluids

Tube: black and oil resistant synthetic rubber.

Reinforcement: four layers of spirally wrapped high tensile steel wire that separated by synthetic rubber fabric layer.

Cover: synthetic rubber. It is weather, oil, fuel, ozone and abrasion-resistant.

Very high-pressure applications subject to surges or flexing such as construction equipment, mining, and the high-performance industrial market.

Tube: High-strength synthetic rubber.

Reinforcement: Four spiral layers of high-strength steel wire.

Cover: Anti-abrasive synthetic rubber, resistant to oils, fuels and atmospheric conditions

Very high-pressure applications subject to surges or flexing such as construction equipment, mining, and the high-performance industrial market.

Tube: black and oil resistant synthetic rubber.

Reinforcement: six or more spiral layers of high-strength steel wire.

Cover: synthetic rubber. It is weather, oil, fuel, ozone and ...

Designed specifically to handle severe, high-pressure applications with pressure spikes or constant hydrostatic loads.

Tube: High-strength synthetic rubber.

Reinforcement: Four layers of high-strength steel wire spiral up to size 1'' ; Six layers of spiral from size 1-1/4'' to 2'' .

Cover: Anti-abrasive synthetic rubber, resistant ...

For applications that require higher pressures, Sinopulse offers a range of four-wire and six-wire spiral hydraulic hoses. These spiral hoses are designed to provide superior performance that exceeds industry standards. Our spiral hoses portfolio includes models designed for low or high temperature, high wear and suction applications, ensuring that we have the perfect solution to meet your hydraulic needs. We offer first-class quality and performance spiral hydraulic hose. Trust Sinopulse to provide the best for your hydraulic applications. Four-wire and six-wire spiral high-pressure hoses are the best choice for high-pressure applications. These hoses can handle higher working pressures and temperatures. At the same time, after continuous research and development and upgrading by Sinopulse, our hoses have higher durability and longer service life, ensuring that you will reduce downtime and replacement times during use, thereby saving long-term costs. With Sinopulse four-spiral and six-spiral hoses, you can trust the quality and performance, making it an ideal choice for industries that require reliable and durable solutions to meet demanding application requirements, to meet your high-pressure hose needs

R12 Spiral Hose features a 4-wire construction with a maximum working pressure of 4000 psi and is designed for hydraulic system service for petroleum, fire-resistant and water-based fluids, fuels and lubrication systems.

R13 Spiral Hose All sizes of this 4-wire and 6-wire construction hose feature a 5100 psi working pressure and are recommended for critical applications in construction, forestry and other off-highway vehicles. Now with 4S/6S spiral hose fittings for world-class performance.

R15 Spiral Hose All sizes of this 4-wire and 6-wire construction hose feature a 6100 psi working pressure and are recommended for extreme duty applications in construction equipment, oil and gas rigs, mining equipment and other high pressure applications. Now with 4S/6S spiral hose fittings for world-class performance.

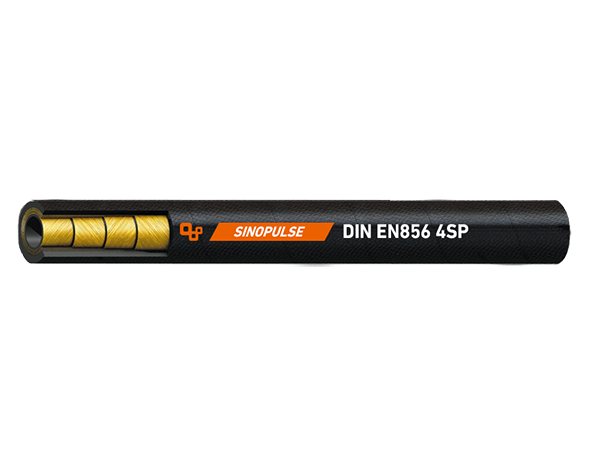

EN856 4SP Spiral Hose is a Four steel wire spiral Hydraulic Hose with a maximum working pressure of 6500psi, mainly used for Mineral and biological oils, water-glycol based, water, lubricants.

EN856 4SH Spiral Hose is extraordinary flexibility, excellent bend radius properties and exceptional impulse life, it can be used in petroleum-based hydraulic fluids of very high pressure and tight bends. It can withstand the temperature of +125°C. Maximum working pressure 6500psi

Pressure range: Typically 5,000 psi or higher (R13)

Temperature Range: – 40ºC to + 125ºC.

Common sizes: includ 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, 1 inch and larger sizes.

Connection accessories: Wire spiral hydraulic hoses are often equipped with threads, flanges or quick connectors on the ends to connect the hose to various components in the hydraulic system, such as hydraulic pumps, valves and hydraulic cylinders.

Wire Spiral Hydraulic Hose Features

Wide range of applications: it is an extremely flexible hose designed to operate at high working pressures and is used in modern construction, marine, mining and forestry equipment.

Impact and abrasion resistant: two, four or six-ply helical steel wire reinforcement provides excellent impact and abrasion resistance for long-lasting, durable performance under the toughest operating conditions.

High pressure resistance: for severe pressure applications requiring high working pressures and excellent impact resistance.

Application scenarios (including but not limited to the following areas):

Our spiral wire hydraulic hose is usually composed of three parts: seamless oil-resistant neoprene tube, high-strength steel wire spiral layer and synthetic rubber with oil resistance, wear resistance and weather resistance. It can also have extraordinary strength under the most demanding high-pressure operations. Its outer layer can resist abrasion and ozone, ensuring the service life and reliable performance of the hose, making it the first choice for applications requiring excellent strength and elasticity, most commonly used in high-pressure hydraulic oil lines.

- Construction machinery: Hydraulic systems used in construction and engineering machinery such as excavators, loaders, bulldozers, etc.

- Agricultural machinery: Hydraulic systems used in agricultural equipment such as agricultural tractors, harvesters, and agricultural vehicles.

- Industrial equipment: Hydraulic systems used in various industrial equipment, such as metallurgy, mining, papermaking, food processing and other fields.

- Construction machinery: Hydraulic systems used in construction equipment such as concrete pumps, tower cranes, and drilling rigs.

- Transportation equipment: Hydraulic systems used in various transportation equipment such as trucks, ships, railway vehicles, etc.

Hot Products

The four wire spiral layers or six wire spiral layers of spiralled wire reinforcement provides superior kick resistance and abrasion resistance for durable, long-lasting performance under the toughest working conditions.

EN 856 4SP Steel Wire Spiraled Hydraulic Rubber Hose Technical Specification

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| EN856 4SP-04 | 1/4″ | 6.4 | 18.0 | 45.0 | 6525 | 180 | 26100 | 150 | 0.620 |

| EN856 4SP-06 | 3/8″ | 9.5 | 20.8 | 44.5 | 6453 | 178 | 25810 | 180 | 0.730 |

| EN856 4SP-08 | 1/2″ | 12.7 | 24.0 | 41.5 | 6018 | 166 | 24070 | 230 | 0.900 |

| EN856 4SP-10 | 5/8″ | 15.9 | 27.6 | 35.0 | 5075 | 140 | 20300 | 250 | 1.130 |

| EN856 4SP-12 | 3/4″ | 19.1 | 31.8 | 35.0 | 5075 | 140 | 20300 | 300 | 1.480 |

| EN856 4SP-16 | 1″ | 25.4 | 39.7 | 28.0 | 4060 | 112 | 16240 | 340 | 1.980 |

| EN856 4SP-20 | 1.1/4″ | 31.8 | 50.8 | 21.0 | 3045 | 84 | 12180 | 460 | 2.910 |

| EN856 4SP-24 | 1.1/2″ | 38.1 | 57.2 | 18.5 | 2683 | 74 | 10730 | 560 | 3.430 |

| EN856 4SP-32 | 2″ | 50.8 | 69.8 | 16.5 | 2393 | 66 | 9570 | 660 | 4.890 |

EN 856 4SH Steel Wire Spiraled Hydraulic Rubber Hose Technical Specification

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| EN856 4SH-12 | 3/4″ | 19.1 | 31.8 | 42.0 | 6090 | 168 | 24360 | 280 | 1.476 |

| EN856 4SH-16 | 1″ | 25.4 | 38.7 | 38.0 | 5510 | 152 | 22040 | 340 | 1.984 |

| EN856 4SH-20 | 1.1/4″ | 31.8 | 46.2 | 32.5 | 4713 | 130 | 18850 | 460 | 2.428 |

| EN856 4SH-24 | 1.1/2″ | 38.1 | 53.5 | 29.0 | 4205 | 116 | 16820 | 560 | 2.871 |

| EN856 4SH-32 | 2″ | 50.8 | 68.0 | 25.0 | 3625 | 100 | 14500 | 700 | 4.534 |

SAE 100R12 Steel Wire Spiraled Hydraulic Rubber Hose Technical Specification

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| SAE 100R12-06 | 3/8″ | 9.5 | 20.2 | 28.0 | 4060 | 112 | 16240 | 125 | 0.707 |

| SAE 100R12-08 | 1/2″ | 12.7 | 23.5 | 28.0 | 4060 | 112 | 16240 | 180 | 0.871 |

| SAE 100R12-10 | 5/8″ | 15.9 | 27.3 | 28.0 | 4060 | 112 | 16240 | 200 | 1.107 |

| SAE 100R12-12 | 3/4″ | 19.1 | 31.0 | 28.0 | 4060 | 112 | 16240 | 240 | 1.339 |

| SAE 100R12-16 | 1″ | 25.4 | 38.0 | 28.0 | 4060 | 112 | 16240 | 300 | 1.984 |

| SAE 100R12-20 | 1.1/4″ | 31.8 | 47.0 | 21.0 | 3045 | 84 | 12180 | 420 | 2.532 |

| SAE 100R12-24 | 1.1/2″ | 38.1 | 54.0 | 17.5 | 2540 | 70 | 10150 | 500 | 3.040 |

| SAE 100R12-32 | 2″ | 50.8 | 67.5 | 17.5 | 2540 | 70 | 10150 | 640 | 4.586 |

SAE 100R13 Steel Wire Spiraled Hydraulic Rubber Hose Technical Specification

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| SAE 100R13-12 | 3/4″ | 19.1 | 31.8 | 35.0 | 5075 | 140 | 20300 | 240 | 1.472 |

| SAE 100R13-16 | 1″ | 25.4 | 39.2 | 35.0 | 5075 | 140 | 20300 | 300 | 1.984 |

| SAE 100R13-20 | 1.1/4″ | 31.8 | 50.0 | 35.0 | 5075 | 140 | 20300 | 420 | 3.519 |

| SAE 100R13-24 | 1.1/2″ | 38.1 | 58.5 | 35.0 | 5075 | 140 | 20300 | 500 | 3.440 |

| SAE 100R13-32 | 2″ | 50.8 | 72.0 | 35.0 | 5075 | 140 | 20300 | 640 | 4.765 |

SAE 100R15 Spiral Steel Wire Spiraled Hydraulic Rubber Hose Technical Specification

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| SAE 100R15-12 | 3/4″ | 19.1 | 31.8 | 42.0 | 6090 | 168 | 24360 | 265 | 1.472 |

| SAE 100R15-16 | 1″ | 25.4 | 39.2 | 42.0 | 6090 | 168 | 24360 | 330 | 1.984 |

| SAE 100R15-20 | 1.1/4″ | 31.8 | 50.0 | 42.0 | 6090 | 168 | 24360 | 445 | 3.519 |

| SAE 100R15-24 | 1.1/2″ | 38.1 | 58.2 | 42.0 | 6090 | 168 | 24360 | 530 | 4.499 |

| SAE 100R15-32 | 2″ | 50.8 | 72.0 | 35.0 | 5075 | 140 | 20300 | 640 | 6.449 |

What is spiral hydraulic hoses

A spiral hydraulic hose, or spiral hose, is a high-pressure hydraulic hose that is a critical part of hydraulic systems used in dozens of industries. Spiral hoses get their name from their reinforcement, which is made of multiple layers of steel wire (usually four or six layers) that are twisted together and stacked in alternating directions to create a "spiral" shape. Of the two main types of rubber hydraulic hoses (braided or spiral), spiral hydraulic hoses are the preferred choice for high-pressure applications and extreme conditions, and the added rigidity of their spiral construction makes them stronger and safer than the more flexible braided hydraulic hoses. However, due to this rigidity, the bend radius of spiral hoses is significantly smaller than that of braided hoses. As with all things, which type of hose to choose depends on the application.

Where can Spiral Hydraulic Hose used?

Spiral hoses are reliable and rugged high-pressure hydraulic hoses that can get heavy-duty jobs done safely and efficiently. They are popular in industries such as construction, mining, agriculture, highway maintenance, and any application that needs to handle high peak pressures and rigorous operating conditions. Spiral hydraulic hoses are versatile and highly sought after. As a result, there are many different categories, types, and sizes of spiral hoses, so finding the right hose and size for your operation can be difficult and overwhelming.

Difference between Spiral and Braided Hydraulic Hoses?

Construction

For braided hoses, as the name implies, this layer consists of steel wires that alternately cross to form a braid. The manufacturing process is fairly complex and requires the use of large braiding machines to form the braid on an extruded inner tube. It also requires an extensive quality inspection protocol to ensure that the braid does not split; otherwise, the thickness of the final product will be affected.

Spiral hoses, on the other hand, also have steel wires wrapped around the inner tube, but instead of interlacing, they are arranged in parallel in a spiral pattern. Manufacturing a spiral hydraulic hose is generally faster than a braided hose because it has the same number of reinforcement layers.

Flexibility

Braided hoses are more flexible than spiral hoses. This is because the interlocking pattern of the braid gives it a higher tensile strength. Spiral hydraulic hoses require additional layers of counter-helix to withstand the same pressure as braided hydraulic hoses, which increases its outer diameter and reduces its minimum bend radius. Therefore, braided hydraulic hoses are ideal for applications that require the hose to be twisted in an unconventional position to be installed.

Durability

Durability is one area where spiral hoses outperform braided hoses. In hydraulic systems where pressure changes occur frequently, the hoses tend to expand and contract to compensate for the peaks and drops in pressure. Over time, these changes can cause braided hoses to lose tensile strength as the tightness between them weakens. Additionally, the friction between the braided wires generates heat, which degrades the performance of the inner and outer tubes. Spiral braids tend to exhibit higher resistance to pressure changes, making them more durable in the long run.

Applications

Most braided hoses are suitable for low- to medium-pressure applications, such as return lines, hydraulic lifts, and large engines. Spiral hoses are ideal for hydrostatic drives that operate at higher pressures and have rapid pressure changes. They are most commonly used in large, specialized heavy machinery, such as mining excavators and off-road dump trucks.

Choose Sinopulse

For 20 years, Sinopulse has been providing our customers with high-quality custom hydraulic hoses and accessories. Our employees design, source, manufacture, and install fluid transfer systems for nearly every type of company, from local petrochemical cleanup services to international mining groups. Regardless of the industry or application, we believe in providing our customers with high-quality service and quality products. Sinopulse produces a wide range of high-quality spiral hydraulic hoses for a variety of applications and offers some of the world's most popular hose product lines. If you need a spiral hose that is resistant to high pressure, has a long service life, and is stable, Sinopulse is your best choice. As a professional hydraulic hose manufacturer, we ensure that our customers have access to the latest hydraulic hose technology and the best products on the market. Sinopulse spiral hoses and high-pressure hydraulic hoses exceed all industry standards for pressure, temperature and abrasion resistance, ensuring your business can operate sustainably.